7 * 24-hour service hotline

+86 15836191545

1、 Product Overview

AFB stainless steel corrosion-resistant centrifugal pumps are improved and designed on the basis of FB corrosion-resistant pumps. All of them adopt new auxiliary impeller power shaft seals, advanced hydraulic models, novel structures and high-strength combined double end mechanical seals, which have the advantages of high energy saving, compact structure, stable performance, reliable use, etc. It is a single-stage single suction cantilever corrosion resistant centrifugal pump. The overflow parts of the pump in contact with the conveying medium are made of 1Cr18Ni9Ti material. It is used to transport corrosive liquid without solid particles. The temperature of the conveyed medium is - 20 ℃~120 ℃, and the inlet pressure of the pump is not more than 2kg/cm2. The double end sealing cooling device can transport high temperature medium of about 300 ℃.

2、 Model meaning

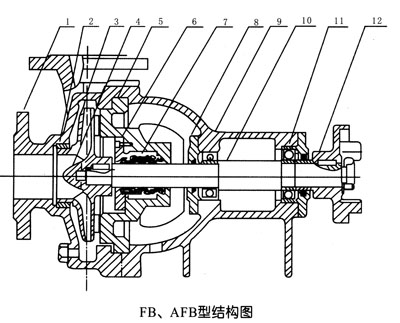

3、 Structural drawing

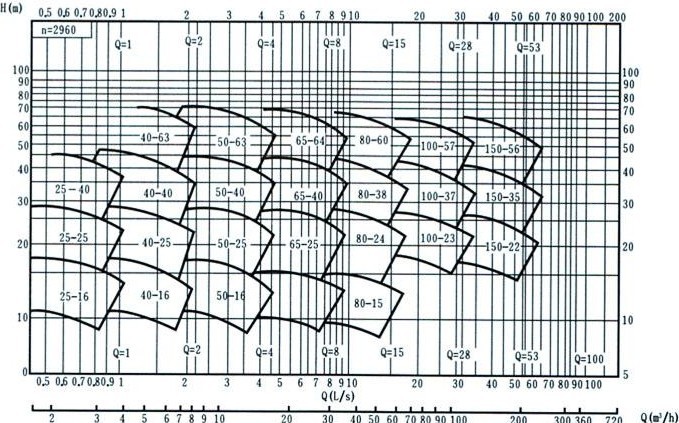

4、 Technical characteristics

5、 Structural characteristics

AFB stainless steel corrosion-resistant centrifugal pump (hereinafter referred to as AFB corrosion-resistant pump) is a single-stage single suction cantilever stainless steel corrosion-resistant centrifugal pump. It absorbs the characteristics of various pumps in the 1990s, adopts advanced hydraulic model, novel structure and high-strength composite double end mechanical seal, and has the advantages of high efficiency, energy saving, compact structure, stable performance, reliable use, etc. The parts at the overflow part of the pump are all made of various corrosion-resistant and wear-resistant alloy steel materials according to different transmission media. The inlet pressure of the pump is generally not more than 0.2MPa, and can reach 0.35~0.4MPa if necessary. The medium temperature is - 20 ° C~+130 ° C. The cantilever stainless steel corrosion-resistant centrifugal pump is widely used in petroleum, chemical, metallurgy, synthetic fiber, medicine, food and other industrial sectors.

6、 Installation and removal

[AFB stainless steel corrosion-resistant centrifugal pump] assembly and disassembly:

1. Disassembly:

Due to the use of extended couplings, it is not necessary to disassemble the inlet and outlet pipelines, pump body and motor when disassembling the pump. It is only necessary to remove the intermediate coupling in the extended coupling to remove the rotor components for maintenance.

1. Remove the drain pipe plug on the pump body and the drain pipe plug on the suspension body, and drain the liquid in the pump and the lubricating oil in the suspension body. (Note: If there are additional pipelines on the pump, they should also be removed).

2. Dismantle the connection between the pump body and the intermediate support, and withdraw all rotor components such as the intermediate support, suspension components and pump cover from the pump body.

3. Remove the impeller nut, impeller and key.

4. Remove the pump cover, coaxial sleeve, mechanical seal end cover, mechanical seal and other components from the shaft. Take care not to slide the shaft sleeve relative to the pump cover, and then remove the mechanical seal together with the shaft sleeve, and then disassemble the shaft sleeve and the mechanical seal.

If packing is used for sealing, the shaft sleeve can be directly removed from the pump cover, and then the packing gland, packing and packing ring can be removed in sequence.

If the seal adopts a special structure, pay attention to different disassembly methods.

5. Remove the intermediate support and suspension support.

6. Remove the pump coupling and key.

7. Remove the dust discs at both ends of the suspension body and the front and rear covers of the bearing, and then remove the shaft and the bearing from the suspension body.

8. Remove the bearing from the pump shaft.

2. Assembly

Reverse the removal procedure.

[AFB stainless steel corrosion-resistant centrifugal pump] Installation:

1. The reasonable installation of the pump has a very important impact on the normal operation and service life of the pump, so it must be carefully calibrated before installation.

2. It must be ensured that the pump will not exceed its allowable NPSH during operation. The pump suction height (or back filling height) must be determined according to the NPSH characteristics of the pump, the resistance loss characteristics of the pipeline and the suction liquid level pressure of high-temperature water.

When the pump is used for suction, the bottom valve shall be installed on the suction pipeline, and the liquid filling screw hole or valve shall be installed on the outlet pipeline for pump filling before starting;

When the pump is used for back filling, valves and filters shall be installed on the suction pipeline to prevent sundries from entering.

3. The suction and discharge pipelines shall be provided with other supports, and the pump shall not be used as the support.

4. The place where the pump is installed shall be convenient for patrol inspection and maintenance.

5. Installation sequence

⑴ Place the unit on the foundation with embedded anchor bolts, and place a pair of wedge pads between the base and the foundation for alignment.

(2) Loosen the coupling. Use a level gauge to place it on the pump shaft or base, adjust the wedge pad, align the level of the unit, and then properly tighten the anchor bolts to prevent walking.

(3) Pour the base and anchor bolt holes with concrete.

(4) After the concrete is dry, the foundation bolts shall be tightened and the levelness of the pump shaft shall be checked.

(5) After connecting the pipeline and determining the rotation direction of the prime mover, connect the coupling, check the concentricity of the shaft again, measure the outer circle of the coupling, the difference between the left and right sides shall not exceed 0.1mm, and the gap between the end faces of the two couplings shall not exceed 0.3mm.

(6) After 3-4 hours of actual operation of the unit, a later inspection shall be carried out. If there is no adverse phenomenon, the installation shall be considered as qualified.

[AFB stainless steel corrosion-resistant centrifugal pump] Start, operation and stop:

1. Preparation before starting

⑴ Clean the pump and site before starting.

(2) Check whether the amount of lubricating oil in the bracket is appropriate (the oil level is about 2mm from the center line of the oil level gauge) and whether the oil level gauge is intact.

(3) Before connecting the coupling, check the rotation direction of the prime mover, and connect the coupling after it is consistent with the rotation arrow of the pump.

(4) After the mechanical seal is installed, the pump shaft can be easily rotated by hand without friction, and the protective cover of the coupling shall be installed.

⑸ The pump shall be used under suction, and the pump shall be filled or vacuumized before starting; The pump is used under the condition of reverse filling. Before starting, the pump shall be filled with the liquid conveyed. After the empty place in the pump is removed, the gate valve of the discharge pipe shall be closed.

(6) Check whether the foundation bolts are loose before starting. Whether the gland is skewed, and the supply of lubricating oil and cooling water.

2. Start

(1) Close the inlet and outlet pressure (or vacuum) gauge and water outlet valve (if there is a bypass pipe, it should also be closed at this time.) Start the motor (it is better to jog the motor first and confirm the correct rotation direction of the pump before starting the formal operation.), Then open the inlet and outlet pressure (or vacuum) gauge. When the pump reaches the normal speed and the instrument indicates the corresponding pressure, slowly open the outlet valve and adjust it to the required working condition. When the discharge pipeline is closed, the pump shall not work continuously for more than 3 minutes.

(2) During the starting process, pay attention to the power reading of the prime mover and the vibration of the pump. The vibration number should not exceed 0.06 mm. The measured position is the bearing seat.

(3) Sealing condition: the mechanical seal shall be free of leakage and heat, and the packing seal shall be in continuous trickle state.

3. Run

⑴ Regularly check the heating of the pump and motor (the temperature rise of the bearing shall not exceed 75 ℃) and the oil supply of the oil level gauge. (Generally, the lubricating oil shall be replaced every 1500 hours of operation).

⑵ The suction valve cannot be used to regulate the flow to avoid cavitation.

(3) The pump shall not operate continuously under the design flow of less than 30%. If it is necessary to operate continuously under this condition, a bypass pipe shall be installed at the outlet to discharge the excess flow.

(4) Pay attention to whether there is noise in the pump operation. If abnormal conditions are found, they should be eliminated or stopped for inspection in time.

4. Stop

(1) Slowly close the gate valve of the discharge and outlet pipeline (if the pump is used under the condition of reverse filling, the gate valve of the suction pipeline shall also be closed), and close the switches of various instruments.

⑵ Cut off the power supply.

(3) If external liquid introduction is adopted for sealing, the liquid introduction valve shall also be closed.

(4) If the ambient temperature is lower than the freezing point of the liquid, the liquid in the pump shall be drained to prevent frost cracking.

(5) If the pump is shut down for a long time, in addition to discharging the corrosive liquid in the pump, all parts shall be disassembled and cleaned, especially the sealing chamber. It is better to dismantle the pump for cleaning and then reassemble it. In addition to oil anti rust treatment and sealing the pump inlet and outlet, regular inspection should also be carried out.

[AFB stainless steel corrosion-resistant centrifugal pump] Precautions for using mechanical seal:

This type of pump can be installed with different forms of mechanical seals according to different service conditions (such as built-in single end balanced and unbalanced, double end balanced and unbalanced, external mechanical seals, etc.) The use method and precautions are different according to the selected seal type. Here are just a few general precautions.

1. As mechanical seals are generally suitable for use in clean, non suspended particle media, newly installed pipeline systems and reservoir tanks should be carefully flushed to prevent solid impurities from entering the mechanical seal end face and causing seal failure.

2. In the medium easy to crystallize, the mechanical seal shall be washed frequently. Clean the crystals on the mechanical seal before restarting after shutdown.

3. The mechanical seal shall be disassembled carefully and shall not be knocked with hammer or iron to avoid damaging the sealing surfaces of the dynamic and static rings.

4. If dirt cannot be removed, try to remove the dirt, and then remove it after flushing to avoid damaging the sealing element.

5. Before installing mechanical seals, check all sealing elements for failure or damage, and repair or replace them if any.

6. The relative friction sealing surface of the moving ring and the stationary ring shall be strictly checked, and no fine scratches, bruises and other defects are allowed. All other parts, including pump body, impeller, sealing chamber, etc., shall be cleaned before assembly, especially the dynamic and static ring temple surfaces, which shall be carefully wiped with clean, soft cloth or cotton yarn, and then coated with a layer of clean grease or engine oil.

7. During assembly, pay attention to eliminate the deviation. When fastening the screws, tighten them evenly to avoid deflection and seal failure.

8. Correctly adjust the compression amount of the spring. After the pump is installed, when you pull the rotor by hand, you should feel that the seal spring has a certain compression amount, but it can rotate quickly and flexibly without the feeling of biting. If it feels too tight or does not move, it should be loosened properly.

9. For mechanical seals with external flushing, the flushing fluid shall be turned on before starting to fill the sealing cavity with sealing fluid. When stopping, stop the pump first, and then turn off the sealing flushing fluid.

Hundreds of customers to choose from