7 * 24-hour service hotline

+86 15836191545

1、 Product overview

This pump integrates self-priming and non clogging sewage discharge. It can not only pump the dirt, sediment, waste ore impurities, feces treatment and all engineering sewage containing large particle solid blocks and long fibers without installing a bottom valve and introducing water, like the general clean water self-priming pump, but also completely reduce the labor intensity of workers, and it is easy to use, move and install, with little maintenance and stable performance.

Scope of use

1. Ambient temperature ≤ 45 ℃, medium temperature ≤ 60 ℃.

2. PH value of medium: 6-9 for cast iron pump and 1-14 for stainless steel pump.

3. The larger diameter of the passing particles is 60% of the pump diameter, and the fiber length is 5 times of the diameter.

4. The total weight of impurities in the medium shall not exceed 15% of the total weight of the medium, and the specific gravity of the medium shall not exceed 1240kg / m3.

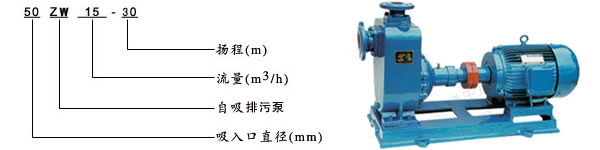

2、 Model meaning

3、 Structure diagram

4、 Technical characteristics

5、 Structural features

ZW type self-priming sewage pump is developed by the designers of our factory according to the structure and performance of ZX type self-priming centrifugal pump and QW type sewage pump, drawing on the advantages of similar products at home and abroad, and absorbing the use requirements and opinions of the majority of users in many aspects. It integrates self-priming and sewage. It does not need to install a bottom valve, irrigation and diversion like ordinary clean water Self-priming pumps, but also can pump the sewage containing large particle solid blocks and long fibers, sediments Waste ore impurities, feces treatment and all engineering sewage and colloidal liquids completely reduce the labor intensity of workers, and are easy to use, move and install, with little maintenance and stable performance.

6、 Installation and removal

7、 Performance parameters

| 型号 | 流量 (m 3 /h) | 扬程 (m) | 功率 (kw) | 转速 (r/min) | 效率 (%) | 汽蚀余量 (m) |

| ZW25-8-15 | 8 | 15 | 1.5 | 2900 | 45 | 2.0 |

| ZW32-5-20 | 5 | 20 | 2.2 | 2900 | 45 | 2.5 |

| ZW32-10-20 | 10 | 20 | 2.2 | 2900 | 45 | 2.5 |

| ZW32-9-30 | 9 | 30 | 3 | 2900 | 48 | 2.5 |

| ZW40-10-20 | 10 | 20 | 2.2 | 2900 | 45 | 2.5 |

| ZW40-20-15 | 20 | 15 | 2.2 | 2900 | 45 | 2.5 |

| ZW40-15-30 | 15 | 30 | 3 | 2900 | 48 | 2.5 |

| ZW50-10-20 | 10 | 20 | 2.2 | 2900 | 45 | 2.5 |

| ZW50-20-12 | 20 | 12 | 2.2 | 2900 | 45 | 2.5 |

| ZW50-15-30 | 15 | 30 | 3 | 2900 | 48 | 2.5 |

| ZW50-20-35 | 20 | 35 | 7.5 | 2900 | 48 | 2.5 |

| ZW65-30-18 | 30 | 18 | 4 | 2900 | 45 | 2.5 |

| ZW65-25-30 | 25 | 30 | 5.5 | 2900 | 50 | 3.0 |

| ZW65-25-40 | 25 | 40 | 7.5 | 2900 | 50 | 3.0 |

| ZW65-40-25 | 40 | 25 | 7.5 | 2900 | 50 | 3.0 |

| ZW65-65-25 | 65 | 25 | 7.5 | 2900 | 52 | 3.0 |

| ZW80-40-16 | 40 | 16 | 4 | 1450 | 50 | 3.0 |

| ZW80-40-25 | 40 | 25 | 7.5 | 2900 | 50 | 3.0 |

| ZW80-25-40 | 25 | 40 | 7.5 | 2900 | 50 | 3.0 |

| ZW80-65-25 | 65 | 25 | 7.5 | 2900 | 52 | 3.0 |

| ZW80-80-35 | 80 | 35 | 15 | 1450 | 45 | 3.0 |

| ZW80-40-50 | 40 | 50 | 18.5 | 2900 | 50 | 3.0 |

| ZW80-50-60 | 50 | 60 | 22 | 1450 | 55 | 3.0 |

| ZW100-100-15 | 100 | 15 | 7.5 | 1450 | 50 | 4.0 |

| ZW100-80-20 | 80 | 20 | 7.5 | 1450 | 53 | 4.0 |

| ZW100-100-20 | 100 | 20 | 11 | 1450 | 53 | 4.0 |

| ZW100-100-30 | 100 | 30 | 22 | 2900 | 53 | 4.0 |

| ZW100-80-45 | 80 | 45 | 37 | 2900 | 55 | 4.0 |

| ZW100-80-60 | 80 | 60 | 37 | 2900 | 53 | 4.0 |

| ZW100-80-80 | 80 | 80 | 45 | 2900 | 50 | 4.0 |

| ZW125-120-20 | 120 | 20 | 15 | 2900 | 55 | 4.5 |

| ZW150-180-14 | 180 | 14 | 15 | 1450 | 60 | 5.0 |

| ZW150-180-20 | 180 | 20 | 22 | 1450 | 60 | 5.0 |

| ZW150-180-30 | 180 | 30 | 37 | 1450 | 65 | 5.0 |

| ZW150-180-38 | 180 | 38 | 55 | 1450 | 45 | 5.0 |

| ZW200-280-14 | 280 | 14 | 22 | 1450 | 65 | 5.0 |

| ZW200-280-20 | 280 | 20 | 37 | 1450 | 62 | 5.0 |

| ZW200-300-25 | 300 | 25 | 45 | 1450 | 59 | 5.0 |

| ZW200-280-28 | 280 | 28 | 55 | 1450 | 55 | 4.8 |

| ZW250-420-20 | 420 | 20 | 55 | 1450 | 61 | 6.0 |

| ZW300-800-14 | 800 | 14 | 55 | 1450 | 65 | 6.0 |

Hundreds of customers to choose from