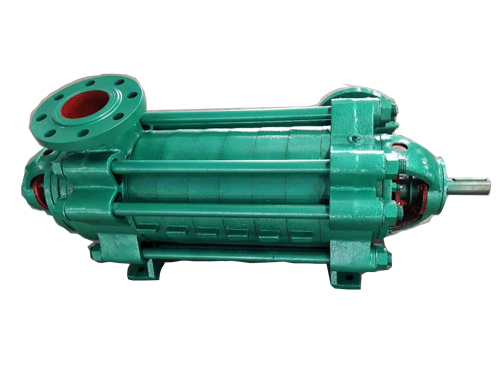

For conveying clean water or other liquids with physical and chemical properties similar to water, the temperature of the liquid shall not exceed 80 ℃. It has the characteristics of high efficiency, wide performance range, safe and stable operation, low noise, long service life, and convenient installation and maintenance.

For conveying clean water or other liquids with physical and chemical properties similar to water, the temperature of the liquid shall not exceed 80 ℃. It has the characteristics of high efficiency, wide performance range, safe and stable operation, low noise, long service life, and convenient installation and maintenance.

7 * 24-hour service hotline

+86 15836191545

Product overview

D-type horizontal multistage pump is a single suction multistage segmented centrifugal pump, which is used for conveying clean water or other liquids with physical and chemical properties similar to water. The temperature of the liquid shall not exceed 80 ℃. It has the characteristics of high efficiency, wide performance range, safe and stable operation, low noise, long service life, and convenient installation and maintenance. It can also be used for conveying hot water, oil, corrosive or abrasive media by changing the material and sealing form of the flow-through parts of the pump and adding a cooling system. The product complies with JB / t1051-93 type and basic parameters of multistage clean water centrifugal pump.

D-type horizontal multistage pump is mainly used for industrial and urban water supply and drainage, pressurized water supply for high-rise buildings, garden sprinkler irrigation, fire-fighting pressurization, long-distance water supply, cold and warm water circulation pressurization and equipment matching for heating, bathrooms, etc., especially for small boiler water supply.

The multistage centrifugal pumps (of our company) are all designed and optimized by computer. The company has strong technical force, rich production experience and perfect detection means, so as to ensure the stability and reliability of product quality.

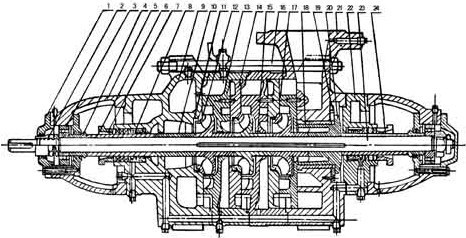

■ structural drawing and description of D-type horizontal multistage centrifugal pump:

1 bearing cover, 2 nut, 3 bearing, 4 water shield sleeve, 5 shaft sleeve frame, 6 shaft sleeve a;

7 packing gland, 8 packing ring, 9 water inlet section, 10 intermediate sleeve, 11 sealing ring, 12 impeller;

13 middle section, 14 guide vane baffle, 15 guide vane sleeve, 16 tension bolt, 17 guide vane of outlet section, 18 Balance sleeve;

19 balance disc, 20 balance ring, 21 outlet section, 22 tail cover, 23 shaft, 24 shaft sleeve b;

Product features:

1. The hydraulic model is advanced with high efficiency and wide performance range.

2. The pump operates smoothly with low noise.

3. The shaft seal adopts soft packing seal or mechanical seal, which is safe and reliable, simple in structure and convenient in maintenance.

4. The shaft is of full sealing structure, which ensures no contact with medium, no corrosion and long service life.

Structure description:

D-type horizontal multistage pump is a multistage segmented pump. Its suction port is located on the water inlet section in a horizontal direction, and its discharge port is vertically upward on the water section. Its head can be increased or decreased according to the use needs. Whether the water pump is well assembled or not has a great impact on the performance, especially the inlet and outlet of each impeller and the inlet and outlet center of the guide vane. If there is a slight deviation, the flow of the water pump will be reduced, the lift will be reduced, and the efficiency will be poor. Therefore, attention must be paid to it during maintenance and assembly.

The main parts of D-type horizontal multistage pump are: inlet section, middle section, outlet section, impeller, guide vane baffle, outlet section guide vane, shaft, seal ring, balance ring, shaft sleeve, tail cover and bearing body.

The inlet section, middle section, guide vane baffle, outlet section guide wing, outlet section and tail cover are all made of cast iron, which together form the working chamber of the pump.

The impeller of D-type horizontal centrifugal pump is made of high-quality cast iron, with blades inside. The liquid enters from one side along the axial direction. Due to the unequal pressure in the front and back of the impeller, there must be axial force, which is borne by the balance plate. The impeller is subject to static balance test during manufacturing.

The shaft is made of high-quality carbon steel, and the impeller is installed in the middle. It is fixed on the shaft with keys, shaft sleeves and shaft sleeve nuts. One end of the shaft is equipped with a coupling component, which is directly connected to the motor.

The sealing ring of D-type horizontal centrifugal water pump is made of cast iron to prevent high-pressure water of the pump from leaking back to the inlet part. It is fixed on the inlet section and the middle section respectively. It is a vulnerable part and can be replaced with spare parts after wear.

The balance ring is made of cast iron and fixed on the outlet section. It and the balance together form a balance device.

The D-type horizontal centrifugal water pump balance plate is made of wear-resistant cast iron and installed on the shaft between the outlet section and the tail cover to balance the axial force.

The shaft sleeve is made of cast iron and located in the packing chamber. It is used to fix the impeller and protect the pump shaft. It is a vulnerable part and can be replaced with spare parts after wear.

The bearing is a single row radial ball bearing, lubricated with calcium base grease.

The packing plays a sealing role to prevent air from entering and a large amount of liquid from leaking out. The packing seal is composed of the inlet section and the packing chamber on the tail cover, the packing gland, the packing ring and the packing. A small amount of high-pressure water flows into the packing chamber to play the role of water seal. The tightness of the filler must be appropriate, not too tight or too loose, and the liquid can seep out drop by drop. If the packing is too tight, the shaft sleeve will easily generate heat and consume power. The packing is too loose, and the efficiency of the water pump will be reduced due to the loss of liquid.

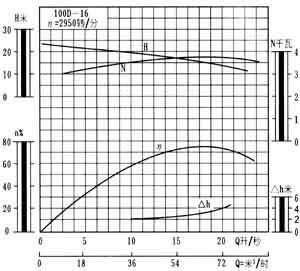

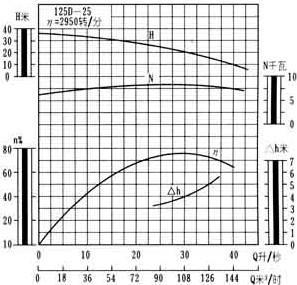

■ performance curve and parameters of D-type horizontal multistage centrifugal pump:

50D-8

100D-16

125D-25

| D/DG/DF/MD(P)6-25 | D/DG/DF/MD(P)6-50 | D/DG/DF/MD(P)6-80 | D/DG/DF/MD(P)12-25 |

| D/DG/DF/MD(P)12-50 | D/DG/DF/MD(P)12-80 | D/DG/DF/MD(P)25-30 | D/DG/DF/MD(P)25-50 |

| D/DG/DF/MD(P)25-80 | D/DG/DF/MD(P)46-30 | D/DG/DF/MD(P)46-50 | D/DG/DF/MD(P)46-80 |

| D/DG/DF/MD(P)85-45 | D/DG/DF/MD(P)85-67 | D/DG/DF/MD(P)85-80 | D/DG/DF/MD(P)85-100 |

| D/DG/DF/MD(P)120-50 | D/DG/DF/MD(P)120-100 | D/DG/DF/MD(P)150-30 | D/DG/DF/MD(P)150-50 |

| D/DG/DF/MD(P)150-80 | D/DG/DF/MD(P)150-100 | D/DG/DF/MD(P)155-30 | D/DG/DF/MD(P)155-67 |

| D/DG/DF/MD(P)200-50 | D/DG/DF/MD(P)200-100 | D/DG/DF/MD(P)200-150 | D/DG/DF/MD(P)210-70 |

| D/DG/DF/MD(P)280-43 | D/DG/DF/MD(P)280-65 | D/DG/DF/MD(P)280-95 | D/DG/DF/MD(P)280-100 |

| D/DG/DF/MD(P)300-45 | D/DG/DF/MD(P)360-40 | D/DG/DF/MD(P)360-60 | D/DG/DF/MD(P)360-95 |

| D/DG/DF/MD(P)450-60 | D/DG/DF/MD(P)450-95 | D/DG/DF/MD(P)500-57 | D/DG/DF/MD(P)550-50 |

| D/DG/DF/MD(P)580-60 | D/DG/DF/MD(P)640-80 | D/DG/DF/MD(P)720-60 | D/DG/DF/MD(P)1100-85 |

Loading, unloading, starting, running and stopping of pump:

(1) Connection sequence:

1) Install the sealing ring on the inlet section and guide vane baffle respectively.

2) Put the guide wing on the middle section, and then install the guide wing baffle on all the middle sections.

3) Pass the installed shaft sleeve a and the suspected shaft through the water bursting section and push them into the impeller. Lay a layer of paper pad on the middle section, install the middle section, and then push in the second impeller. Repeat the above steps to complete the installation of all impellers and middle sections.

4) Install the balance ring, balance sleeve and guide wing of the outlet section on the outlet section respectively.

5) Install the outlet section on the middle section, and then fasten the inlet section, middle section and outlet section together with tensioning bolts.

6) Install the flat washer and shaft sleeve b (this is not available for 50dB pump).

7) Install the paper pad on the tail cover, install the tail cover on the outlet section, and install the packing, packing ring and packing gland into the inlet section and the packing chamber of the tail cover in sequence.

8) Install the bearing body onto the water inlet section and the tail cover respectively, and fasten with bolts.

9) Install the bearing locating sleeve,? L ball bearing and fixed with nuts.

10) Put a proper amount of grease into the bearing body, put a paper cushion on the bearing cover, install the bearing cover on the bearing body and fasten it with screws.

11) Install coupling components, vent cock and all square plugs.

Disassembly shall be carried out in the opposite steps.

(2) Installation:

1. Preparation before installation.

1) Check the water pump and motor.

2) Prepare tools and lifting machinery.

3) Check the foundation of the machine.

2. Installation sequence:

1) When the complete set of water pump is delivered to the site, the motor has been installed for those with the base. It is not necessary to remove the water pump and motor when finding the flat base.

2) Place the base on the foundation, pad wedge-shaped sizing blocks near the anchor screws, and pad the base about 20 ~ 40mm high, ready to fill with water screw slurry after leveling.

3) Check the levelness of the base with a level gauge. After leveling, tighten the anchor nut and fill the base with cement paste.

4) After 3-4 days of cement dry consolidation, check the levelness again.

5) Wash and remove the dirt on the support plane of the base, the water pump foot and the motor foot;,, Put the water pump and motor on the base.

6) Adjust the level of the pump shaft, properly tighten the nut after leveling to prevent walking, install the motor after the adjustment is completed, and place an iron plate at the place that is not level,

There is a certain clearance between the pump and the coupling.

7) Place a leveling ruler on the coupling to check whether the axis of the water pump coincides with the axis of the motor. If the platform is not heavy, place a thin sheet at the foot of the motor or pump to make the outer circles of the two couplings level with the leveling ruler, then take out several thin iron sheets, replace the iron sheets with a planed whole iron plate, and recheck the installation.

In order to check the accuracy of installation, measure the clearance between the two coupling planes with feeler gauges at several opposite positions. The difference between the large and small clearances on the coupling plane in a circle shall not exceed 0.3mm, and the difference between the lower or left and right center lines at both ends shall not exceed 0.1mm.

(3) Start and stop:

1) Clean the grease on the shaft and other oiled parts.

2) Clean the bearing and oil chamber with gasoline and wipe them with cotton yarn.

3) Add calcium based spring oil into the bearing body.

4) The test is successful. Check whether the rotation of the motor is correct. Strictly prevent the nut from loosening when the water pump starts. Then start the motor.

5) Inject water into the pump or empty the pump to draw water.

6) Close the valve and pressure gauge cock on the discharge pipe.

7) After the above process, start the motor and open the pressure gauge cock

8) When the water pump is running at the normal speed, the pressure gauge shows the appropriate pressure Then open the rotary base of the vacuum gauge and gradually open the gate valve on the drainage pipeline to the required pressure.

9) When stopping the water pump, slowly close the gate valve on the drainage pipeline, close the vacuum gauge cock, stop the motor, and then close the pressure gauge cock.

10) When the water pump is stopped for a long time, the water pump shall be disassembled, the water of pump parts shall be wiped away, and the sliding surface shall be coated with anti rust oil for proper storage.

(4) Operation:

1) Pay attention to the bearing temperature of the water pump. It shall not exceed the outside temperature 351, and its limit temperature shall not be greater than 751^

2) The normal water leakage in the material room is not more than 15ml per minute. The compaction degree of the packing gland should be adjusted at any time.

3) Regularly check the shaft protector and pay attention to the temperature rise of the motor bearing.

4) In case of noise or abnormal sound during operation, stop the machine immediately to check the cause.

For performance parameters, please go to the pump selection page for direct inquiry

Hundreds of customers to choose from