7 * 24-hour service hotline

+86 15836191545

BF corrosion-resistant centrifugal pump is used to transport corrosive liquid without solid particles. The temperature of the medium to be transported is - 20 ℃~105 ℃. The pump inlet is 0.6Mpa. The flow is Q3.36~190.8m3/h, and the lift is H5.2~100m.

• Flow: 2-191m ³/ h

• Lift: 5.2-70m

• Efficiency: 17% - 80%

• Pump weight: 40-194kg

• Motor power: 0.75-75kw

NPSH: 2.0-7.0m

Product Overview

BF corrosion-resistant chemical pump is a single-stage single suction cantilever corrosion-resistant chemical centrifugal pump. The company absorbs the characteristics of various pumps in the 1990s, adopts advanced hydraulic model, novel structure and high-strength combined single and double end mechanical seal, and has the advantages of high efficiency, energy saving, compact structure, stable performance, reliable use, etc.

This chemical pump is suitable for conveying corrosive liquid without solid particles. The temperature of the medium to be transported is - 40 ℃~105 ℃, and the double end seal cooling device can be used to transport high temperature medium with the medium temperature below 300 ℃.

All chemical pumps of the company are designed and optimized by computer. The company has strong technical force, rich production experience and perfect detection means, so as to ensure the stability and reliability of product quality.

performance parameter

Technical parameters and model significance of BF corrosion resistant chemical centrifugal pump:

Flow: 2 ~ 191m3/h;

Lift: 5.2~70m;

Rotating speed: 980/1480/2980r/min;

Power: 0.75~75KW;

Inlet diameter: 25~150mm;

High working pressure: 2.0Mpa.

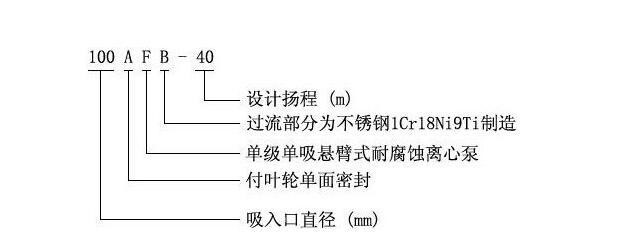

Model description example: 100FB-37A

100 - Pump suction diameter (mm)

F - Single suction single-stage cantilever corrosion resistant chemical centrifugal pump

The overflow part of the B-pump in contact with the transmission medium is made of stainless steel 1Cr18Ni9Ti.

37 - Pump design point lift value (m)

A - Cutting of impeller outer diameter.

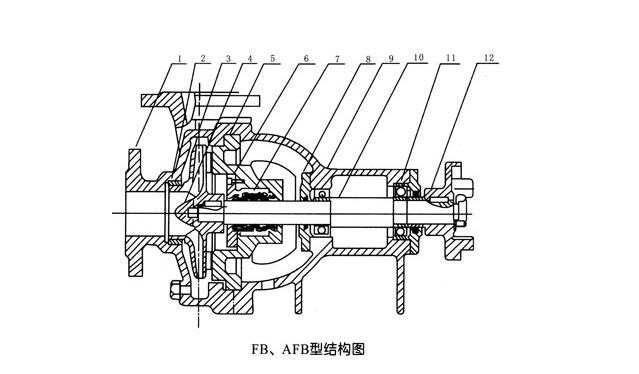

Structure description of BF corrosion resistant chemical centrifugal pump:

1 Pump housing, 2 seal rings, 3 impellers, 4 impeller nuts, 5 pump covers, 6 sealing covers, 7 mechanical seals, 8 bearing covers, 9 bearing bodies, 10 pump shafts, 11 bearings, 12 couplings.

Rotation direction of the pump: from the suction inlet to the motor end, the pump rotates in the needle direction.

The pump and motor are installed on the same base through elastic coupling.

The shaft seal device of the pump adopts a new structure of secondary impeller decompression and double end mechanical seal. The seal chamber is filled with high-quality calcium grease grease and equipped with an oil cup.

Application of BF corrosion resistant chemical centrifugal pump:

FB type non chemical pump is widely used in chemical, petroleum, metallurgy, light industry, synthetic fiber, environmental protection, food, medicine and other departments. This kind of product adopts double end mechanical seal, which plays a great role in improving product quality, reducing leakage, leakage, leakage, pollution prevention and improving the environment. The utility model has the advantages of stable and reliable performance, good sealing performance, beautiful appearance, convenient use and maintenance, etc.

Pump installation and removal:

1. Before installing the mechanical seal, check all components for damage. If damaged, repair or replace it.

2. The friction end faces of the moving ring and the stationary ring shall be strictly checked, without any slight collision or scratch. Before assembly, the end faces of the moving ring and the stationary ring shall be coated with a layer of clean engine oil.

3. During assembly, attention shall be paid to eliminating the deviation, and the compression amount of the spring shall be adjusted correctly to prevent it from being too loose or tight. Tighten the screws evenly to avoid deflection and seal failure.

4. Pay attention to the disassembly sequence of the pump during disassembly.

Pump instructions:

start:

1. Prepare necessary hands and tools.

2. Check whether the lubricating grease in the oil cup of the sealing device is filled.

3. Check whether the rotation direction of the pump is correct. Reverse rotation is strictly prohibited. Wrong rotation can loosen the impeller nut, which may lead to corrosion when the corrosive medium enters the journal, causing the pump to fail to work, and may also cause the impeller nut to throw out, causing an unfortunate accident. Before starting the pump, the coupling must be covered to ensure safe production.

4. When the installation position of the pump is lower than the liquid level (reverse filling), the gate valve of the pipeline shall be opened before the pump is started, and the pump liquid shall fill the pump. If the installation position is higher than the liquid level (vacuum condition), the pump shall be filled and vented before starting, so that the pump and suction pipeline are filled with liquid and the air in the pump is exhausted.

5. After starting the motor, slowly open the gate valve at the outlet to make the pump work normally, and then open the valve to the required level.

stop it:

1. Close the gate valve of the pressure pipeline.

2. Stop the motor.

3. Close the gate valve of suction pipeline.

4. When the ambient temperature is lower than the freezing point of the liquid, drain the liquid in the pump.

5. If the pump is out of service for a long time, the corrosive medium in the pump shall be discharged and washed with clean water. After cleaning, it shall be properly kept.

work:

1. The temperature rise of pump and motor shall be checked frequently, mainly the bearing temperature rise, and the bearing temperature shall not exceed 73 ℃.

2. In the process of operation, if noise and other abnormal sounds are found, the inspection shall be stopped immediately, and the operation can only be started after troubleshooting.

3. Pay attention to the oil filling cup of the sealing device, keep the oil storage, replenish and ensure lubrication in time.

4. Mechanical seals are used in clean media free of suspended particles. Therefore, pay special attention to cleaning the pipeline for the new pipeline system.

For performance parameters, please go directly to the pump selection page

Hundreds of customers to choose from