7 * 24-hour service hotline

+86 15836191545

UHB-ZK series mortar pump (fluoroplastic pump) is a cantilever single-stage, single suction centrifugal pump. Its flow passage components are steel lined UHMWPE structure, which has strong corrosion resistance and wear resistance.

• Flow: 5-500m ³/ h

• Lift: 7-80m

• Motor power: 0.75-110kw

• Price: 4900-52500

• Shaft power: 0.72-103.2kw

Product Overview

UHB chemical corrosion-resistant mortar pump is a single-stage single suction cantilever chemical centrifugal pump, also known as desulfurization pump and filter press pump. It is specially designed and developed for conveying corrosive media containing fine particles. The flow passage part is made of steel lined ultra-high molecular weight polyethylene (UHMWPE), which is a new generation of corrosion-resistant and wear-resistant engineering plastics for pumps in the world. Its outstanding advantage is that it has excellent wear resistance among all plastics Impact resistance (especially low temperature impact resistance), creep resistance (environmental stress cracking resistance) and excellent corrosion resistance. At the same time, metal matrix structure is used to improve the pressure bearing capacity of the product.

UHB chemical pump can adapt to various working conditions. For example, it can not only transport acid and alkali clear liquid or slurry, but also various corrosive slurry in smelting industry, as well as various dilute acids in sulfuric acid industry and various sewage in environmental protection industry. It can transport the slurry of sulfuric acid, nitric acid and hydrochloric acid with a concentration below 80%, 50% and other acids, alkalis and salts, various corrosive mortars and foods in rare metal smelting industry, and various mixed media in liquor industry. The pump is resistant to corrosion and wear, and has a wide range of applications.

UHB chemical pumps have been used in acid pulp and dilute acid posts in more than 30 large non-ferrous smelting and sulfuric acid enterprises for a long time, and their corrosion resistance and wear resistance, sealing reliability and service life have been highly evaluated.

performance parameter

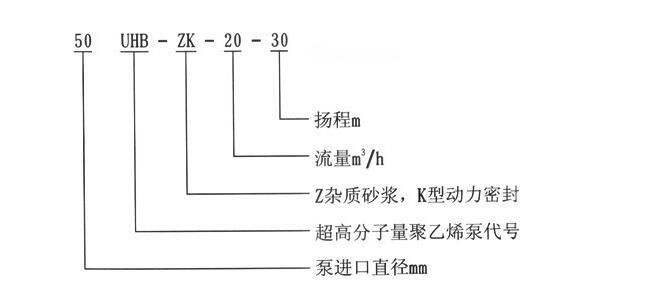

Model meaning of UHB chemical corrosion resistant mortar pump:

UHB-ZK80/50-30

UHB: chemical pump made of polymer materials

80: it indicates that the pump inlet diameter is 80 mm

Z: It means that the pump can transport impurities mortar

50: indicates that the pump flow is 50 m3/h

K: It indicates that the impeller of the pump is semi open

30: indicates that the pump lift is 30 m

Main features of UHB chemical corrosion resistant mortar pump:

UHB chemical centrifugal pump is a kind of pump that can adapt to various working conditions, such as transporting acid, alkaline clear liquid or slurry; Various corrosive pulp in smelting industry; Various dilute acids in sulfuric acid industry; All kinds of sewage in environmental protection industry. The pump is resistant to corrosion and wear, and has a wide range of applications. It has the following characteristics:

1) Strong abrasion resistance: all flow passage parts are made of steel lined UHMW-PE. The abrasion resistance of UHMW-PE ranks first among plastics, 4 times higher than nylon 66 (PA66) and polytetrafluoroethylene (PTFE), and 7-10 times higher than that of carbon steel and stainless steel.

2) Strong impact resistance: The impact strength of UHMWPE ranks first in general engineering plastics, five times that of (acrylonitrile/butadiene/styrene) copolymer (ABS), and it can remain stable at minus 196 ℃, which is a characteristic that no other plastics have.

3) Excellent corrosion resistance: the pump can withstand various corrosive media (acid, alkali, salt) and organic solvents within a certain temperature and concentration range, and immerse in 80 organic solvents at 20 ℃ and 90 ℃ for 30 days. There is no abnormal appearance, and other physical properties are almost unchanged.

4) Noisy: UHMWPE has the middle high value of impact energy absorption of plastic and good sound attenuation, which greatly reduces the noise generated by liquid flow during transportation.

5) Safe, reliable, toxin free decomposition: the pump uses ultra-high molecular weight polyethylene (UHMW-PE) with extremely stable chemical properties, so it is also suitable for use in the food industry.

6) Low friction coefficient: the internal friction system of the pump is only 0.07-0.11, so it has self-lubricating property. Under the condition of water lubrication, its dynamic friction coefficient is half lower than PA66 and POM. When working in the form of sliding or rotating, the lubricating property is better than that of steel and brass after being lubricated.

7) Good viscosity resistance: Ultra high molecular weight polyethylene (UHMW-PE) has excellent viscosity resistance, and its adhesion resistance is equivalent to that of PTFE, so it is also outstanding when transporting some media with high viscosity.

Performance introduction:

1) UHB chemical mortar pump is corrosion resistant and wear-resistant, one pump is multi-purpose, and acid and alkali clear liquid slurry is applicable.

2) The pump body is of steel lined UHMWPE structure, and the lining thickness is 8~20mm. The patented plastic lining technology is applied to the pump. Compared with other similar pumps, the pump has the advantages of good thermal deformation resistance of the lining layer, crack resistance, anti falling off, and high service temperature.

3) The impeller can be divided into two types: closed type and separated type, which can be selected according to the medium condition.

4) Seals: K-type power seal, K1 type power seal, T-type packing seal, T1 type packing seal, C3 type non-standard seal.

5) Applicable medium: sulfuric acid with a concentration below 80%, nitric acid with a concentration below 50%, hydrochloric acid with various concentrations, and liquid alkali, which are applicable to both clear liquid and slurry.

4) Main technical parameters: operating temperature - 20 ℃~ 80 ℃ (using modified materials, it can be increased to more than 100 ℃), inlet diameter 32mm ~ 350mm, flow rate 5 ~ 2600m3/h, and lift within 80m.

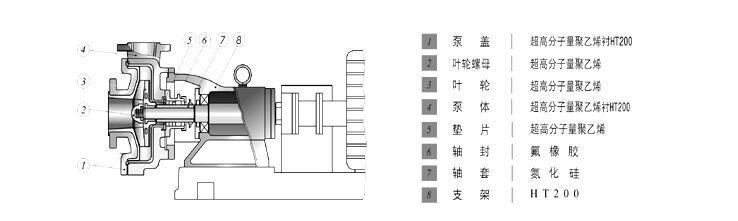

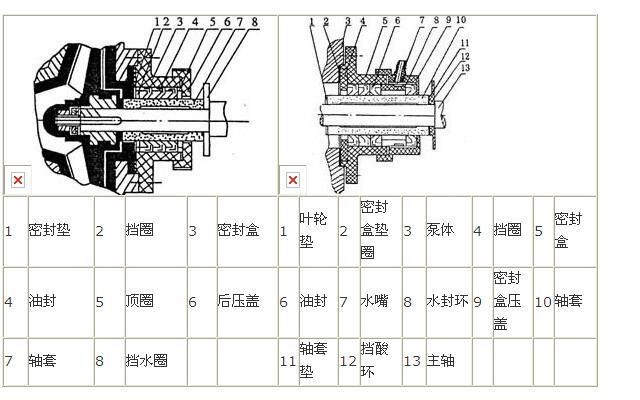

Structural drawing and structural sealing structure of UHB chemical corrosion resistant mortar pump:

(一)K型动力密封(二)带冷却水K型动力密封

Application of UHB chemical corrosion resistant mortar pump:

1. UHB-ZK chemical mortar pump is used for the transportation of dilute acid, mother liquor, sewage, seawater, fluorosilicic acid containing silica gel, phosphoric acid slurry and other media in the sulfuric acid and phosphorus fertilizer industry.

2. UHB-ZK chemical mortar pump is used in the non-ferrous metal smelting industry: it is especially suitable for the transportation of various acid solutions, corrosive mineral slurry, slurry (matched with filter press) electrolyte, sewage and other media for hydrometallurgy of lead, zinc, gold, silver, copper, manganese, cobalt, rare earth, etc.

3. UHB-ZK chemical mortar pump is used in chemical and other enterprises: various sulfuric acid, hydrochloric acid, alkaline, oil clear liquid or slurry posts. Production of titanium dioxide and iron red powder, production of various dyes and pigments, non-metallic mineral processing and other industries.

4. UHB-ZK mortar pump is used in chlorine alkali industry: hydrochloric acid, liquid alkali, electrolyte, etc.

5. UHB-ZK mortar pump is used in water treatment industry: pure water, high purity water, sewage (leather sewage, electroplating sewage, electronic sewage, papermaking sewage, textile sewage, food sewage, domestic sewage, pharmaceutical sewage, etc.).

6. For iron and steel enterprises: sulfuric acid and hydrochloric acid posts of pickling system, sewage with impurities.

7. For wet desulfurization circulating pump: it can be used in alkaline, acidic and corrosive posts at the same time.

8. Used for the transportation of corrosive liquid and coal slurry in coal industry and coal chemical industry; Pumps are used for coal washing.

Startup, operation and maintenance of chemical mortar pump:

1. Preparation before operation:

Before the test run, turn the coupling or shaft manually to check whether the rotation direction is correct and whether the operation is flexible, if not. If there is abnormal noise or movement, it should be checked in time. When checking, first check whether the coupling is horizontal from the outside by hand, and check whether the position of the lubricating oil is near the centerline of the oil mirror from the oil mirror hole on the bearing pedestal (too much should be drained, too little should be added). Check and turn while checking. If the problem still exists, remove the pump to check, (please refer to the structural sketch and disassembly procedures in this manual when removing the pump) and remove foreign matters, And contact with our factory to negotiate the solution.

2. Start up steps:

a. Fill the pump with liquid

b. Open the inlet valve in time (if the inlet and outlet valves are one-way check valves, manual operation is not required)

c. Power on

d. Open the tap valve

3. Run:

In case of abnormal sound or motor heating during operation, the machine shall also be stopped for inspection. The inspection method and steps are the same as those in 1.

4. Shutdown steps:

a. Close the valve at the outlet first

b. Cut off the power supply and timely close the valve at the inlet; (If the inlet valve is a one-way check valve, manual operation is not required)

5. Maintenance

a. The lubricating oil in the bearing pedestal shall be replaced regularly, and it shall be replaced once every six months under normal conditions.

b. In cold seasons, if there is ice formation after the pump is stopped, the cooling water at the seal shall be connected first, and if necessary, the water can be heated to thaw, then the coupling shall be turned by hand until the operation is flexible, and then the machine shall be started according to the starting steps.

c. For the pump with cooling water device, the cooling water shall be connected before starting. When the pump is in normal operation, it can be connected continuously. If conditions do not permit, it can also be stopped. There is no requirement for the flow and pressure of cooling water, so tap water can be used;

d. The operation of the pump when the outlet valve is closed is called the closed pressure operation state. The closed pressure operation time of the full plastic pump or plastic lined pump should be shortened as much as possible. The normal temperature medium should not exceed 5 minutes, and the high temperature medium should not exceed 2 minutes;

e. For the pumps with the center opening casing, such as the imported pump with the diameter of more than 50mm, the sealing plastic at the center opening has some changes due to thermal expansion and cold contraction. During installation, the connecting bolts at the center opening should be checked and tightened first, and then the inlet pipeline should be connected to prevent the leakage of the center opening, which is particularly important for users in the north;

f. The pump cannot bear the weight of the inlet and outlet pipes. The shorter the inlet pipe is, the better. The vertical distance from the pump outlet to the valve should be as short as possible;

g. Ensure that there is no water trace on the motor to prevent the motor from being damped.

Disassembly procedure of chemical mortar pump:

1. Without auxiliary impeller (pump with inlet diameter ≤ 125mm)

Disassembly sequence: (refer to the structure diagram in this manual)

a. Loosen the connecting bolts between the pump body 5 and the pump cover, and remove the pump cover

b. Loosen impeller cap 2 (left-hand thread) and anti rotation nut 3 (left-hand thread), and remove impeller 4

c. Loosen the connecting bolts between the pump body 5 and the bearing seat 10, and remove the pump body 5

d. Loosen the connecting bolts between the seal box 6 and the pump body 5, and remove the seal box 6

e. Unscrew the rear pressure cup on the seal box and take out the oil seal

The installation sequence is opposite to the removal sequence. Note:

After assembling the impeller cap tightly, check the vertical clearance between the impeller and the pump body, which is required to be about 2mm

b. After installing the pump cup, check the gap between the pump cover and the impeller (looking in from the sunrise). The gap should be about 2mm. For high temperature medium, the gap should be about 2.5mm

c. If the clearance 1 between the impeller and the pump body fails to meet the requirements, it can be adjusted by adding or removing shims between the impeller and the shaft sleeve

d. If the clearance between the pump cover and the impeller cannot meet the requirements, it can be adjusted by adding or removing shims between the pump body and the pump cover

2. Pumps with auxiliary impeller (pumps with inlet diameter>125mm)

Disassembly sequence: (refer to the structure diagram in the manual)

a. Loosen the connecting bolts between the pump body 5 and the pump cover l, and remove the pump cover 1

b. Loosen the impeller cap. 2 (left-hand thread>and anti rotation nut 3 (left-hand thread), and remove the impeller 4

c. Loosen the connecting thread between the pump body 5 and the bearing seat 12, and the connecting bolt between the seal box 7 and the pump body, and remove the pump body 5

d. Remove the auxiliary impeller, seal box, oil seal and shaft sleeve in turn

The installation sequence is opposite to the removal sequence. Note:

a. After the impeller cap and the nut behind the water retaining ring are relatively tightened, check the gap between the lower impeller of Ling II and the pump body, which is required to be about 2.5mm

b. After installing the pump cover, check the clearance between the pump cover and the impeller (looking inward from the outlet). The clearance should be about 2mm. For high temperature media, the clearance should be 2.5mm

c. If the clearance between impeller and pump body does not meet the requirements, it can be adjusted by adding or removing shims between impeller and shaft sleeve

d. Pump cover: If the clearance between the pump cover and the impeller does not meet the requirements, it can be adjusted by increasing or decreasing the gasket between the pump body and the pump cover.

For performance parameters, please go directly to the pump selection page

Hundreds of customers to choose from