7 * 24-hour service hotline

+86 15836191545

1、 Product Overview

DL and DLR vertical multistage centrifugal pumps are new multistage pumps developed by Yangzijiang Pump Industry Co., Ltd. according to the actual needs of high-rise building water supply market and the National Fire Protection Bureau GB6245 Performance Requirements and Test Methods for Fire Pumps. DL vertical multistage centrifugal pump is used to transport media without hard particles and with physical and chemical properties similar to water. The flow range is 5~360m3/h, the lift range is 22~300m, the supporting power range is 1.5~220KW, and the caliber range is φ 40~ φ 200m。 One to five outlets can be set at the outlet of the same pump, with low speed n=1450r/min.

2、 Model meaning

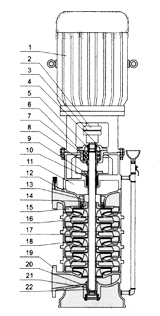

3、 Structural drawing

4、 Technical characteristics

Flow: 4.2-504m3/h;

Lift: 24-240m;

Power: 1.5-450kw;

Rotating speed: 1480r/min;

Caliber: φ 40- φ 250;

Temperature range: 0 -+90 ℃;

Working pressure: ≤ 2.4Mpa.

5、 Structural characteristics

1. Advanced hydraulic model: high efficiency, wide performance range.

2. The centrifugal pump has a novel structure and reliable operation: the balance drum is canceled, and its axial force is hydraulically balanced, which completely solves the problem that the balance drum is easy to rust, bite and wear, and ensures more reliable operation.

3. Less operation and maintenance costs: high-quality mechanical seals are used, which are wear-resistant, leak free, long service life, low failure rate, and have less operation and maintenance costs.

4. The centrifugal pump runs stably with low noise: low speed motor is used to make the pump run stably with low noise.

5. Vertical structure, small floor area.

6、 Installation and removal

Check the intactness of water pump and motor.

2. The pump shall be installed as close to the water source as possible.

3. There are two ways to install the pump and the base, one is the rigid connection directly installed on the cement foundation, and the other is the flexible connection installed with JGD shock absorber

The specific method is shown in the installation diagram.

4. For direct installation, the pump can be placed on the foundation and padded 30~40mm high (for filling cement slurry), and then calibrated, and the anchor bolts shall be put in place for filling

The cement mortar shall be recalibrated after the cement dries up for 3-5 days, and the nuts of anchor bolts shall be tightened after the cement dries up completely.

5. When installing the pipeline, the inlet and outlet pipelines shall have their own supports, and the flange of the pump shall not bear too much pipeline weight.

6 The pump is used in the situation with suction head. The inlet pipe end should be equipped with a bottom valve, and the inlet and outlet pipes should not have too many bends, and there should be no water leakage or air leakage.

7. Filter screen shall be installed on the inlet pipeline to prevent impurities from entering the impeller. The effective area of the filter screen shall be 3~4 times the area of the inlet pipe to ensure liquid

The body is free and smooth.

8. For the convenience and safety of maintenance and use, install a regulating valve on the inlet and outlet pipelines of the pump and a pressure gauge near the pump outlet to ensure

The pump operates within the rated range to ensure the normal operation and service life of the pump.

9. If the inlet needs expanding connection, please select eccentric reducing pipe joint.

Hundreds of customers to choose from