7 * 24-hour service hotline

+86 15836191545

summary

SA (Sam, saf, sap, SLA) single-stage double suction split centrifugal pump is used for conveying various industrial water, domestic water, tap water, water conservancy projects, irrigation and drainage of farmland, etc. the medium temperature is - 20 ℃ - 80 ℃.

SA is used to transport corrosive liquid containing a certain amount of solid particles.

Sam type is used to transport corrosive liquid containing a certain amount of solid particles.

Saf type is used for conveying various corrosive liquids.

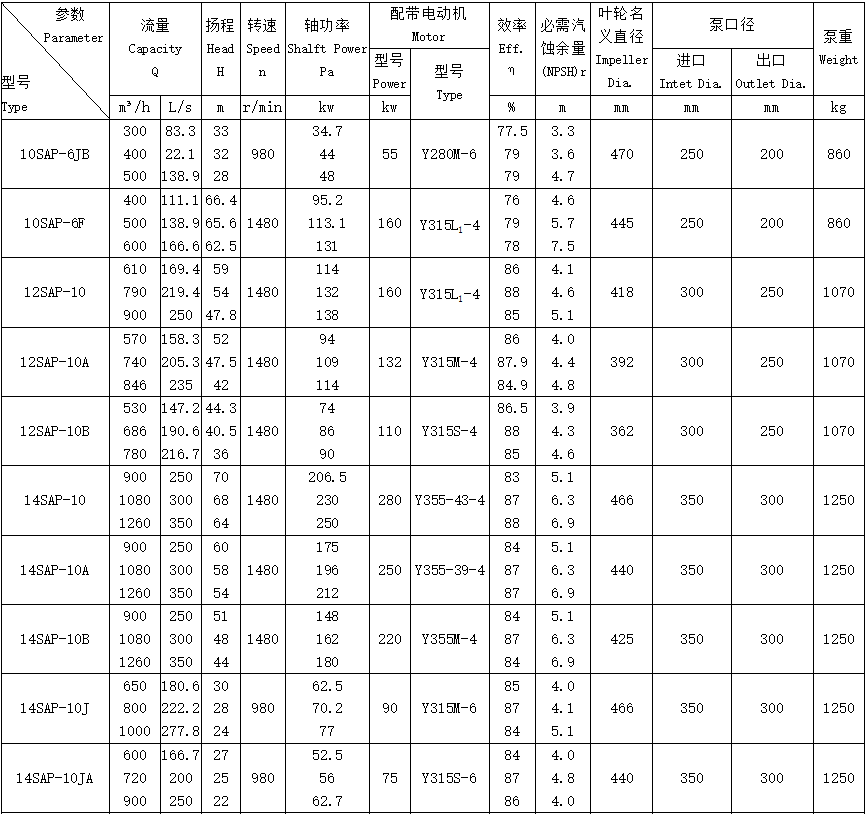

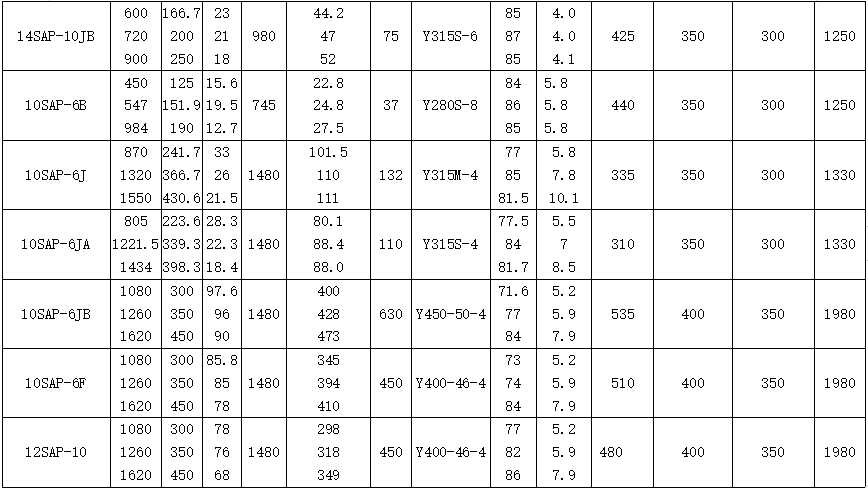

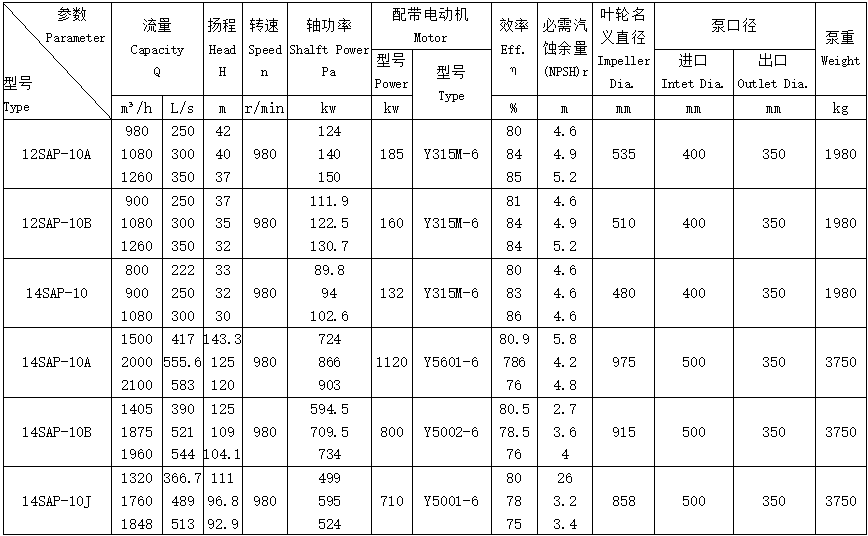

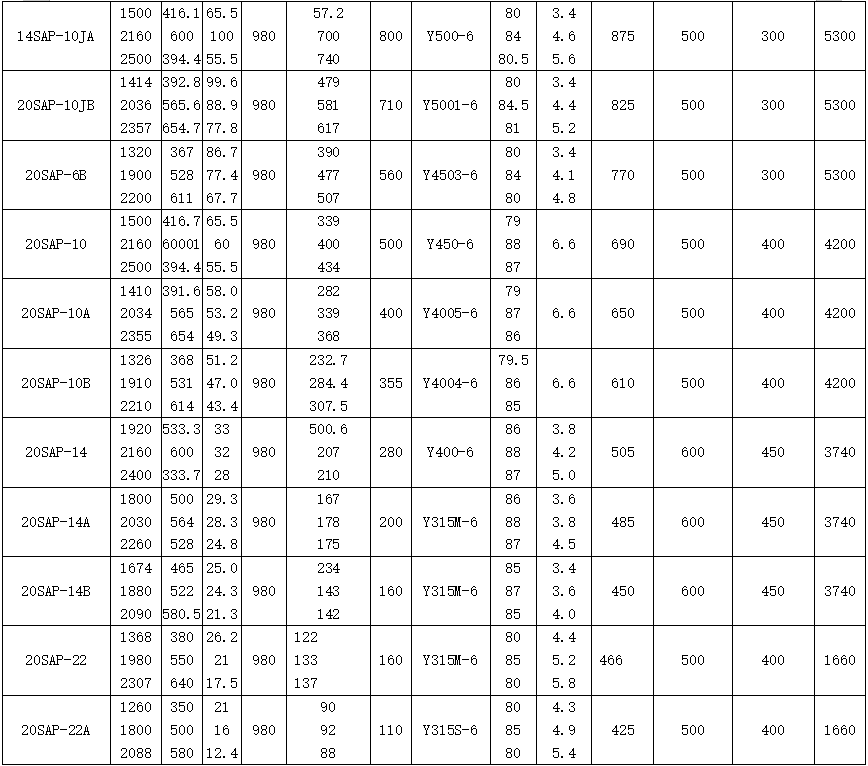

SAP type is a new type of pump modified and expanded on the basis of SA type pump absorbing and digesting the advanced technology of similar pumps abroad.

Model description

Example: 10sa (SAP, Sam, saf, SLA) - 6A

10 - the suction diameter is divided by 25 (i.e. the suction diameter is 250mm)

SA single suction double suction centrifugal clean water pump

SAP - SA improved pump

Sam wear resistant single stage double suction centrifugal pump

Saf - abrasion resistant single-stage double suction centrifugal pump

6-divisor of specific revolution divided by 10

A - impeller outer diameter change

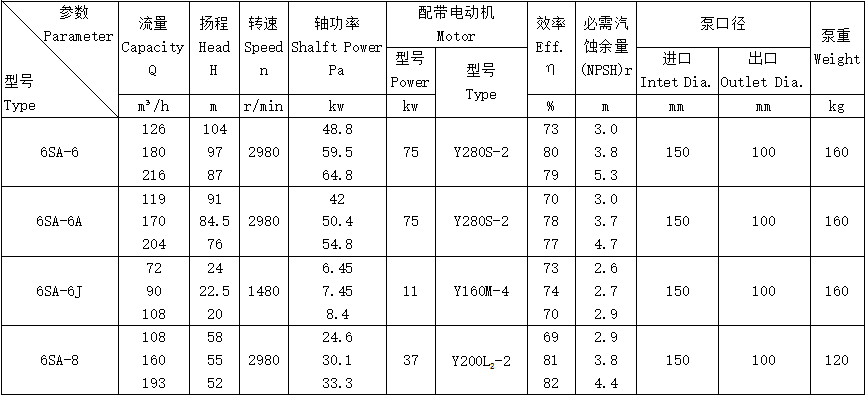

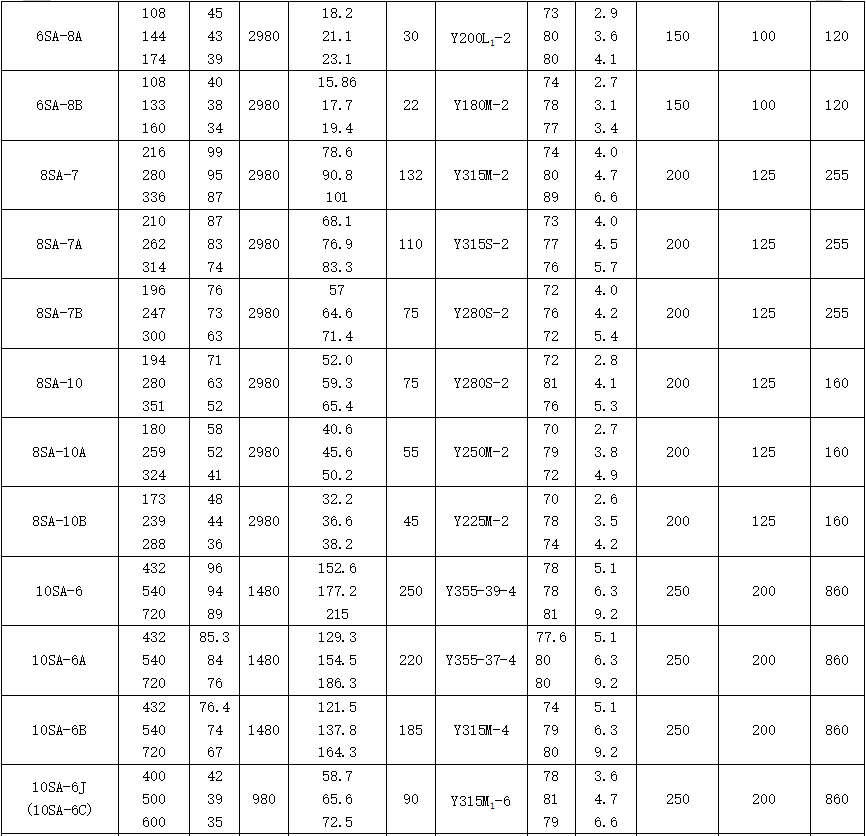

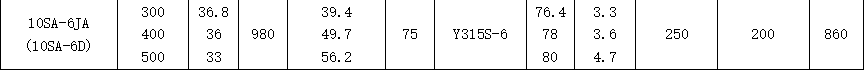

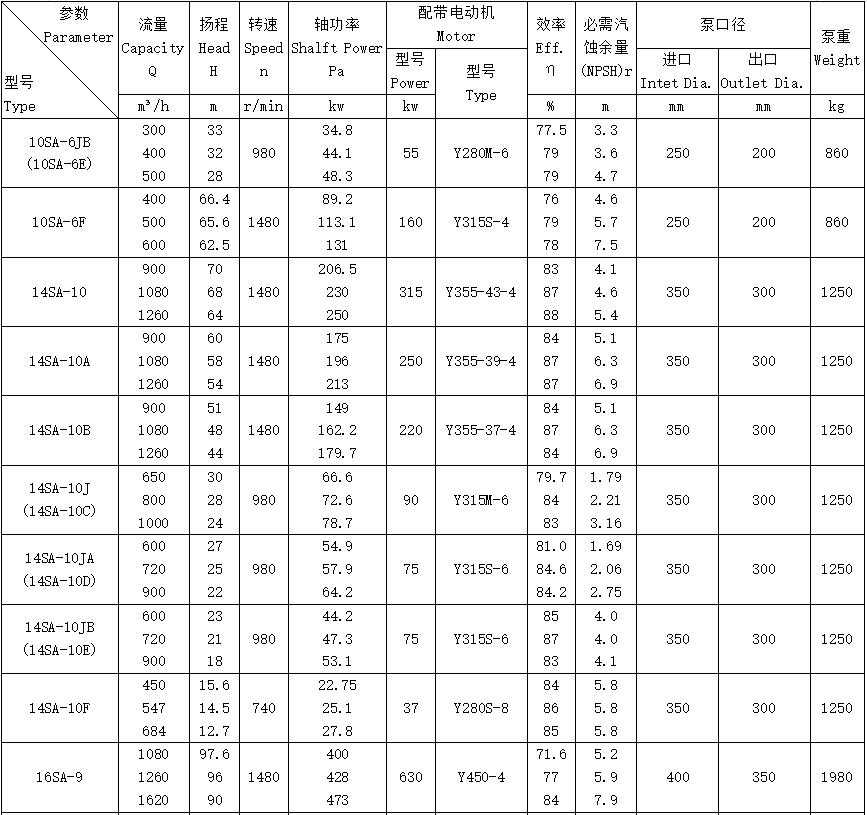

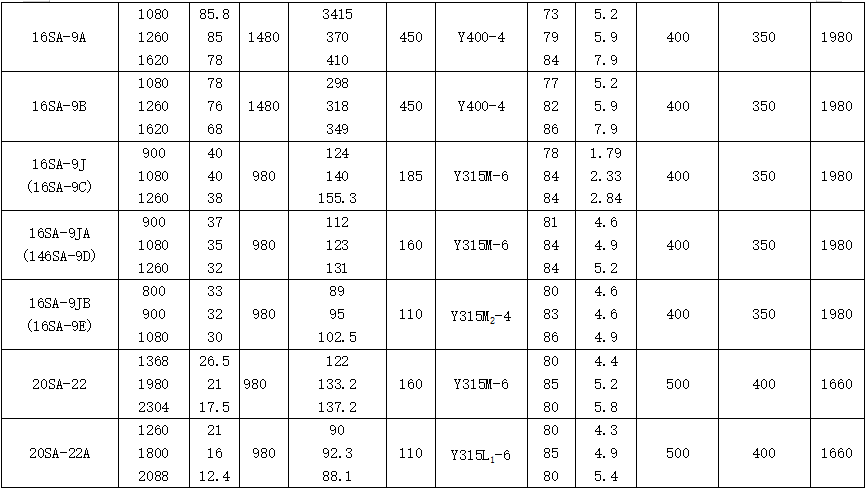

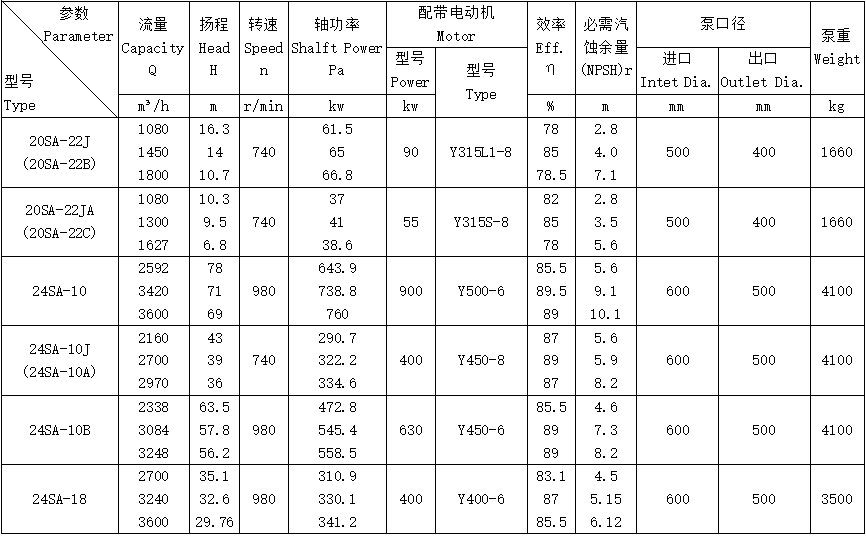

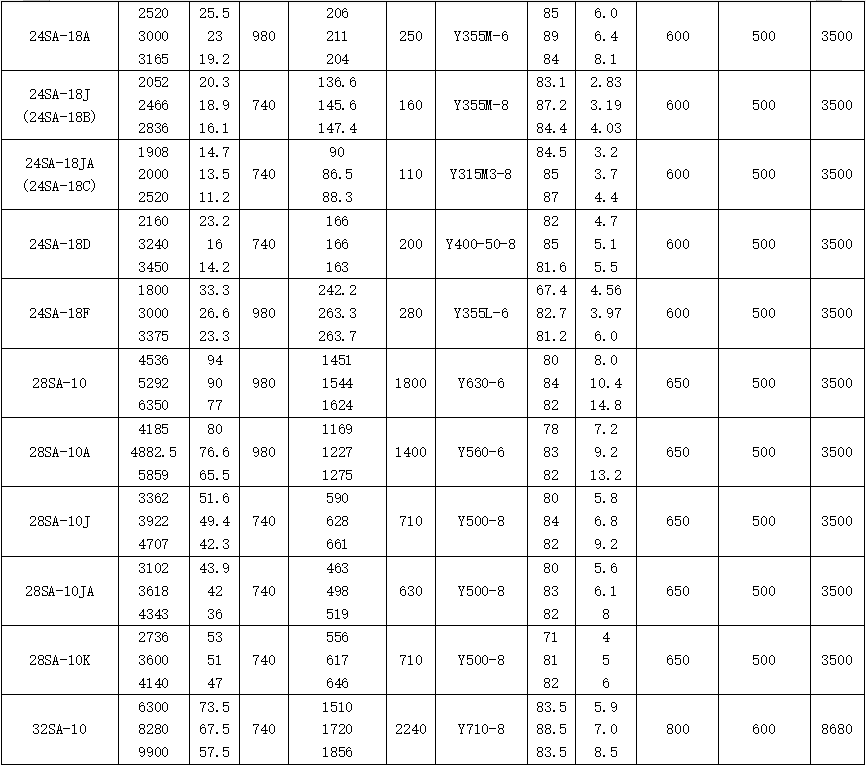

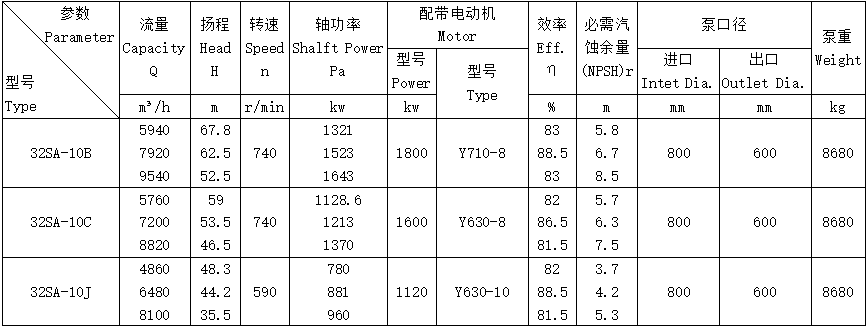

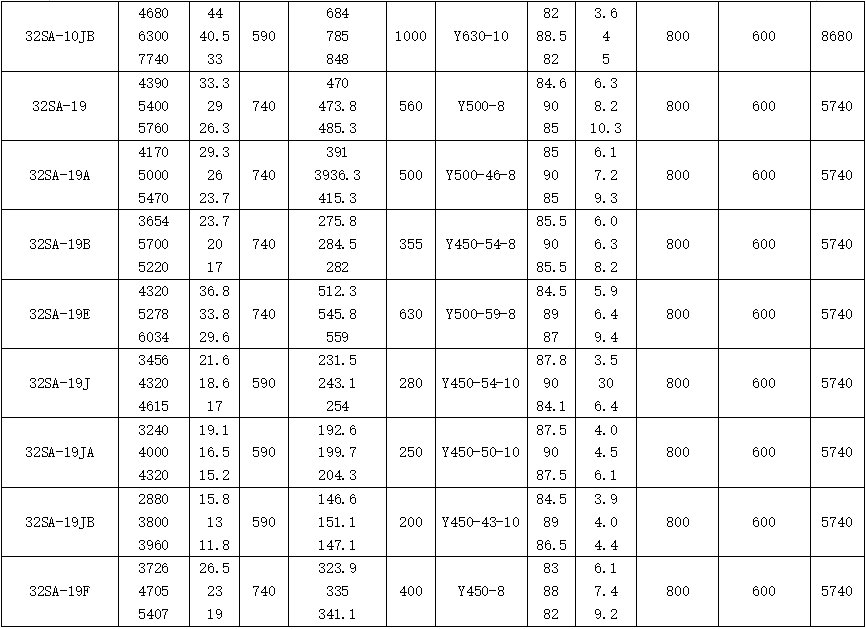

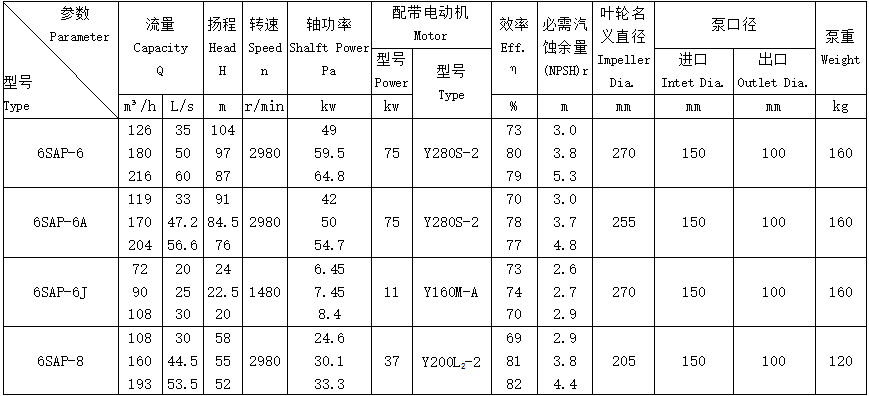

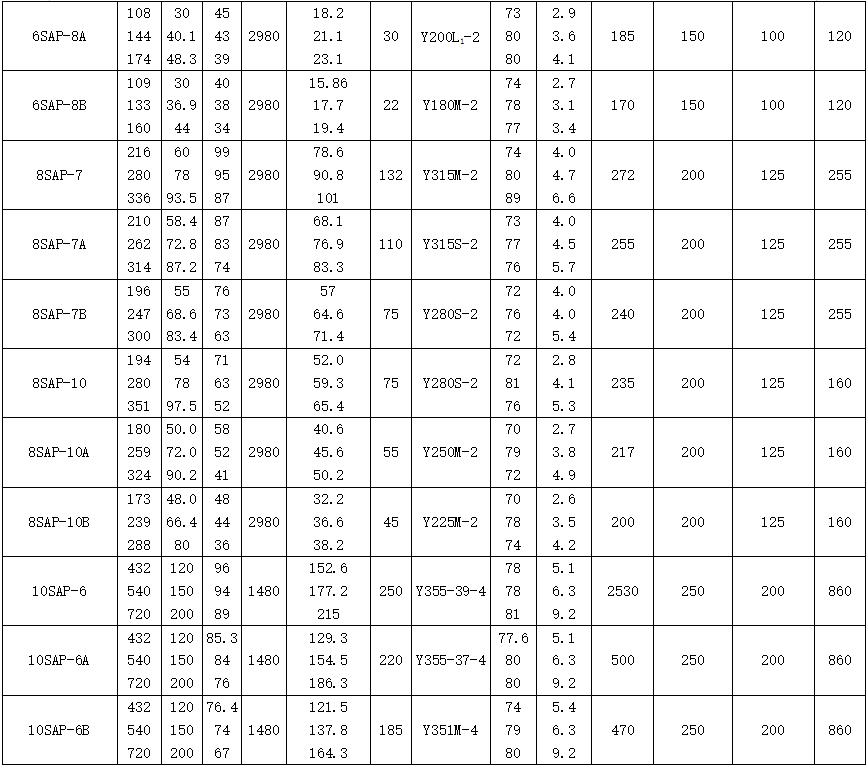

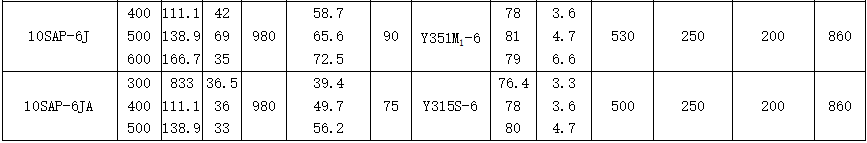

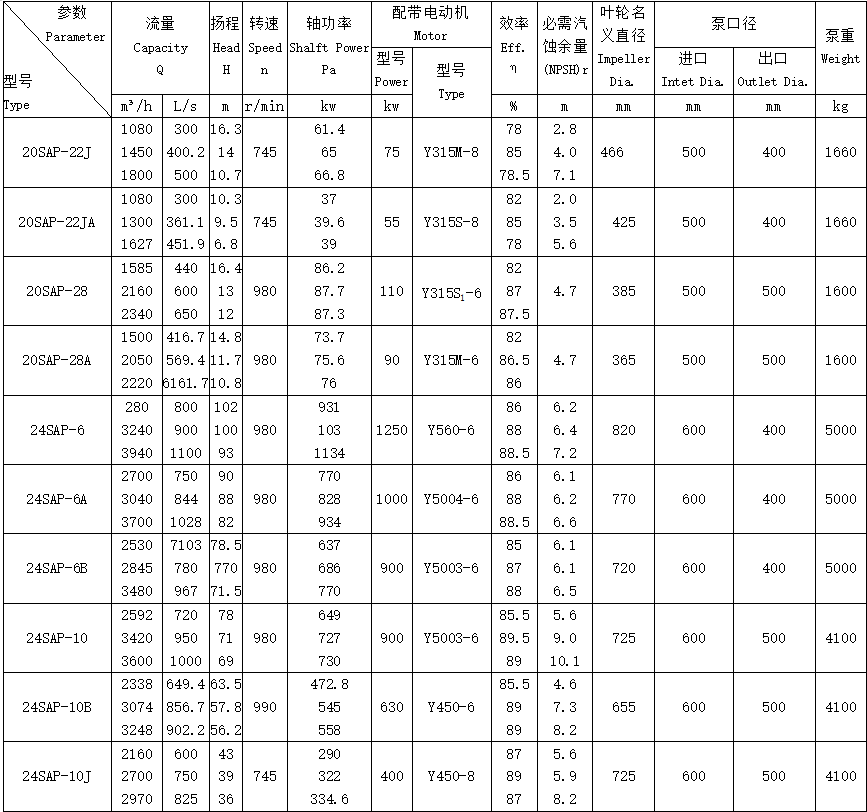

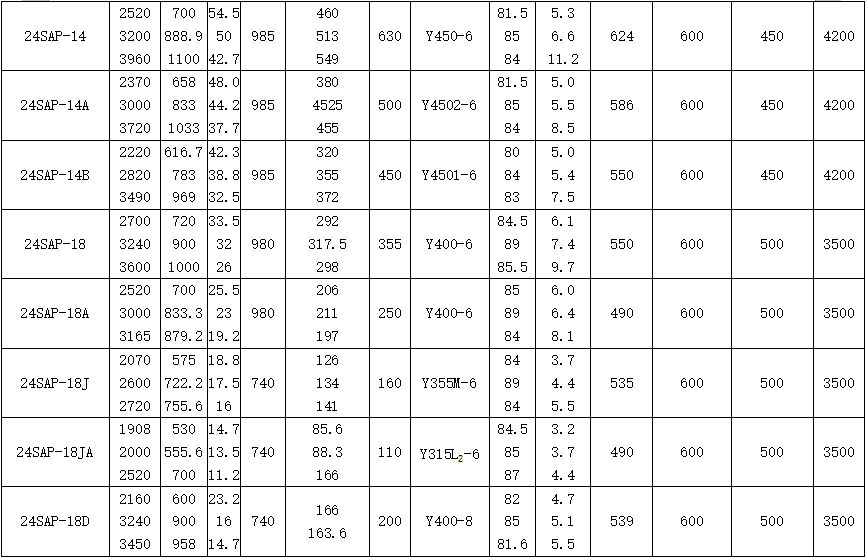

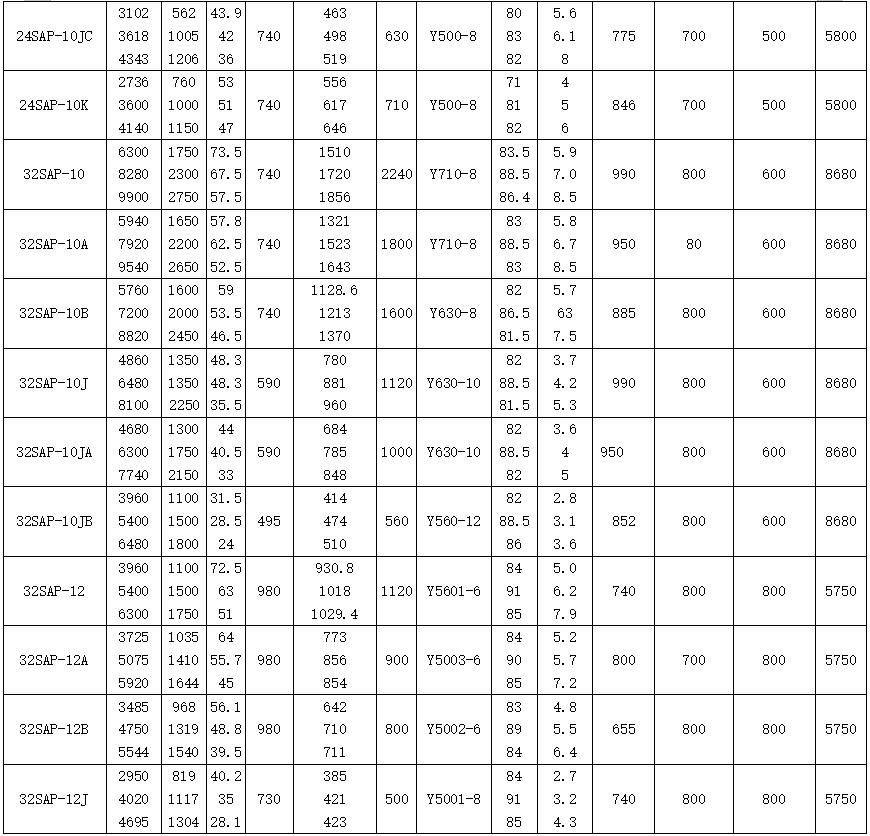

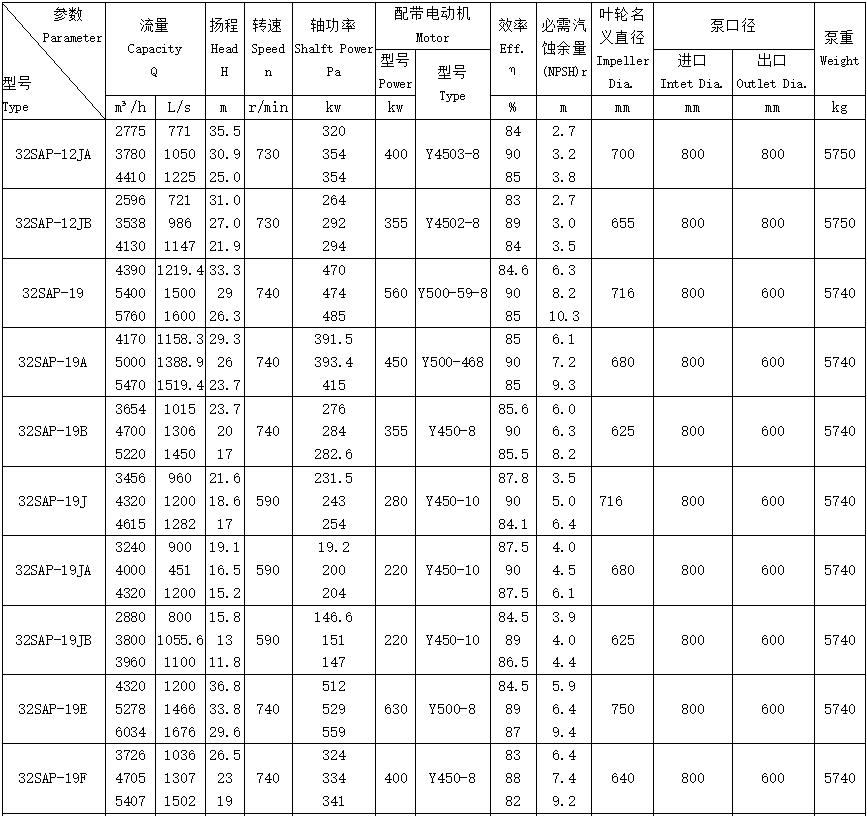

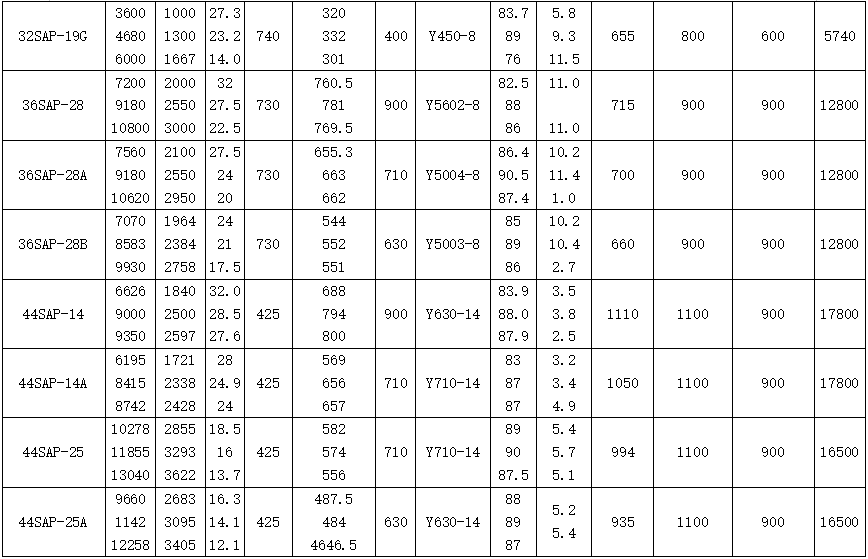

Performance range

Flow: q = 90 ~ 6300m ³/ h

Lift: H = 9.5 ~ 105m

instructions

SA (Sam, saf, SAP) type pumps are installed horizontally. The suction inlet and outlet are both below the center line of the pump shaft. The pump body is horizontally split. It is not necessary to disassemble the inlet and outlet pipes during maintenance.

SLA is installed vertically, with the suction and discharge ports in the horizontal direction, and the separation surfaces of the pump body and pump cover are vertically separated on the axis centerline.

Bearing: both ends of the pump are rolling bearings (24sa-18 and 16sa-90 can be selected as sliding bearings) to support the rotor components, which are lubricated with thin oil grease.

Shaft seal: 1. Soft packing seal; 2. Mechanical seal

Rotation direction of the pump: Viewed from the motor end, the pump rotates counterclockwise or clockwise as required by the user.

Hundreds of customers to choose from