7 * 24-hour service hotline

+86 15836191545

◎ overview

This series of pumps adopts the hydraulic model of high-efficiency and energy-saving products recommended by the state. Through our company's continuous updating and research, it has the advantages of high efficiency, wide performance range, safe and stable operation, low noise, convenient installation and maintenance, long service life, and reliable product performance.

This series of pumps is mainly used in mines. Its flow-through parts and vulnerable parts are made of wear-resistant materials, which can be used to transport neutral mine and similar sewage with solid particle content ≤ 15%, particle size ≤ 5mm and temperature below 80 ℃.

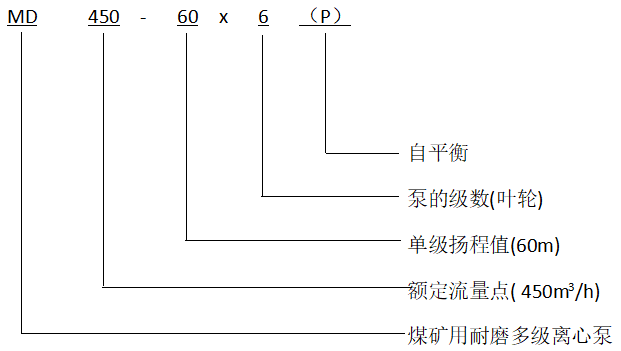

◎ model description

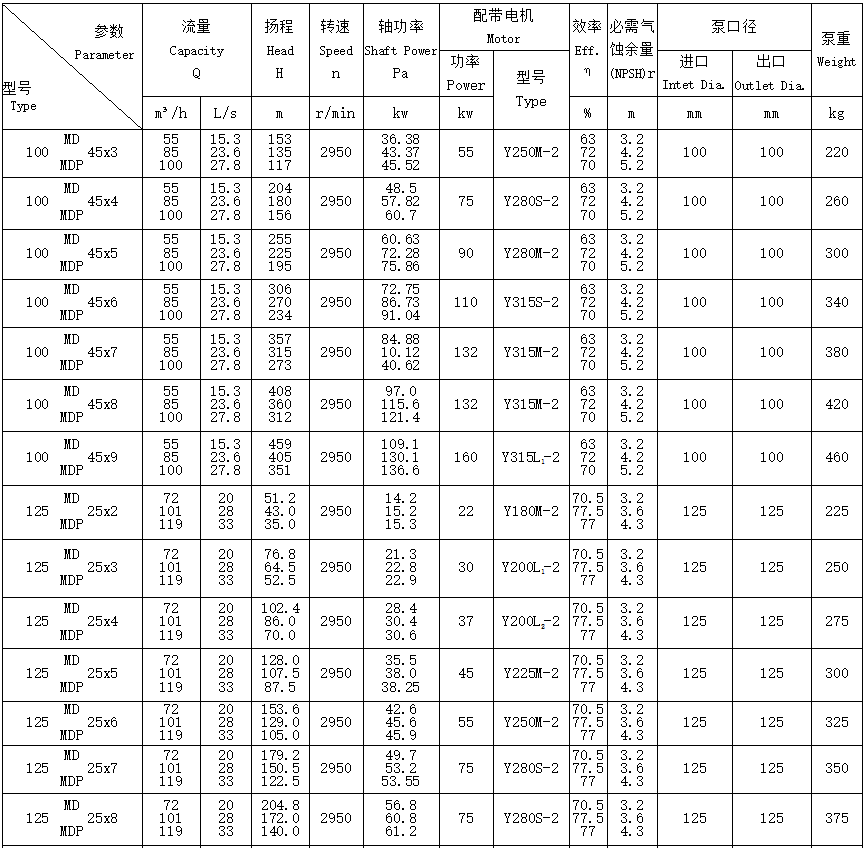

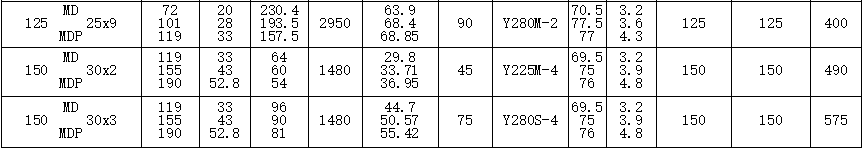

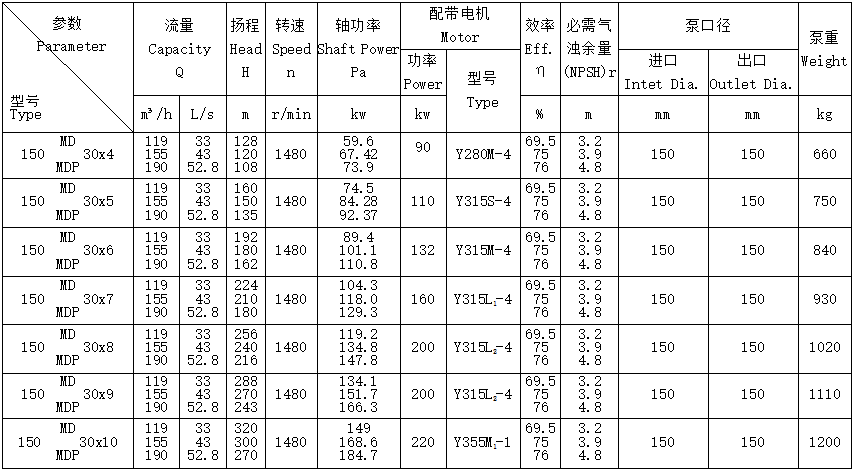

Example: md280-43x6 example: 150md30x3

MD wear resistant multistage centrifugal pump 150 pump suction diameter is 150mm

280 pump design point flow: 280M3 / h MD abrasion resistant multistage centrifugal pump

43 - single stage lift of pump design point is 43M; 30 - single stage lift of pump design point is 30m

6 - the number of pumps is 6, and 3 - the number of pumps is 3

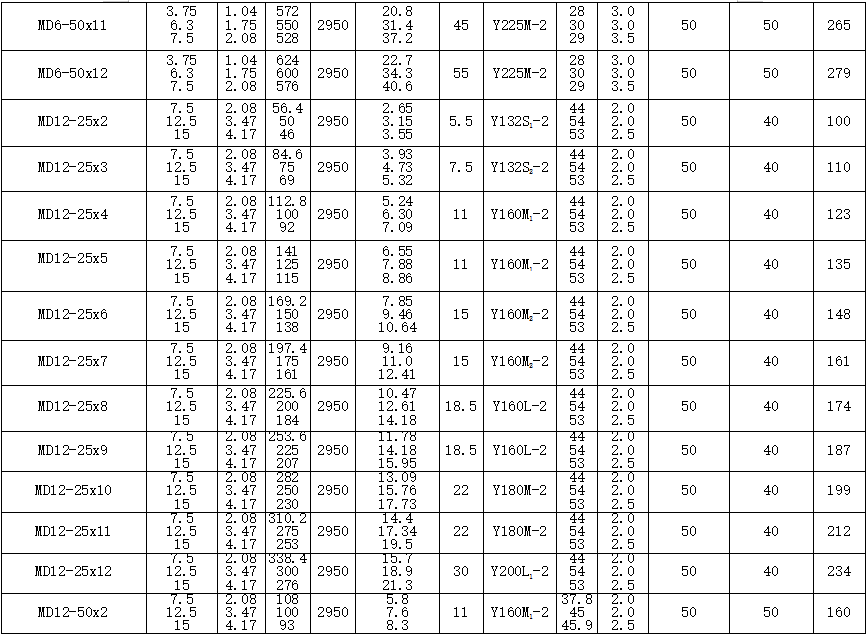

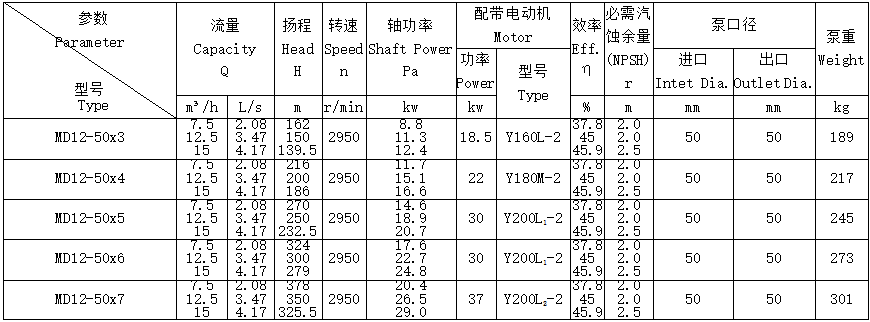

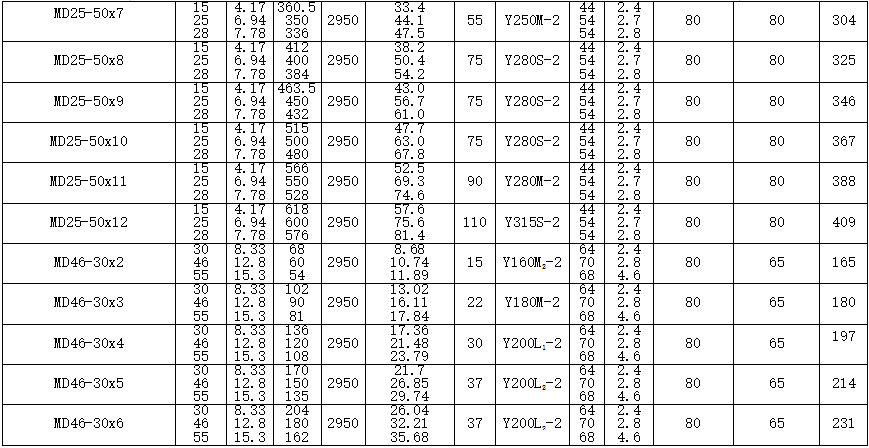

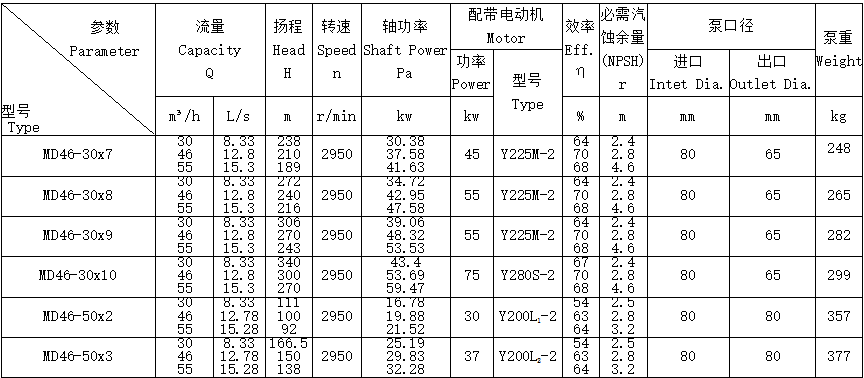

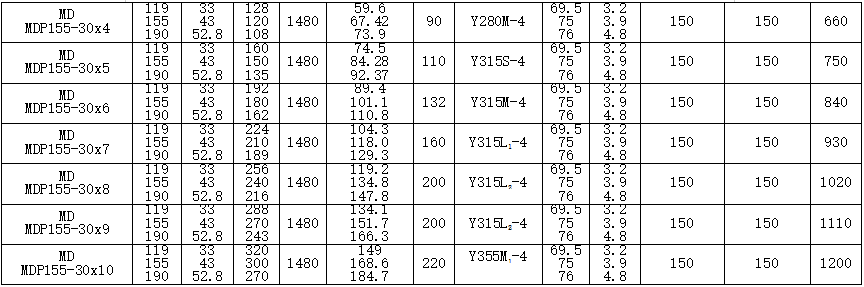

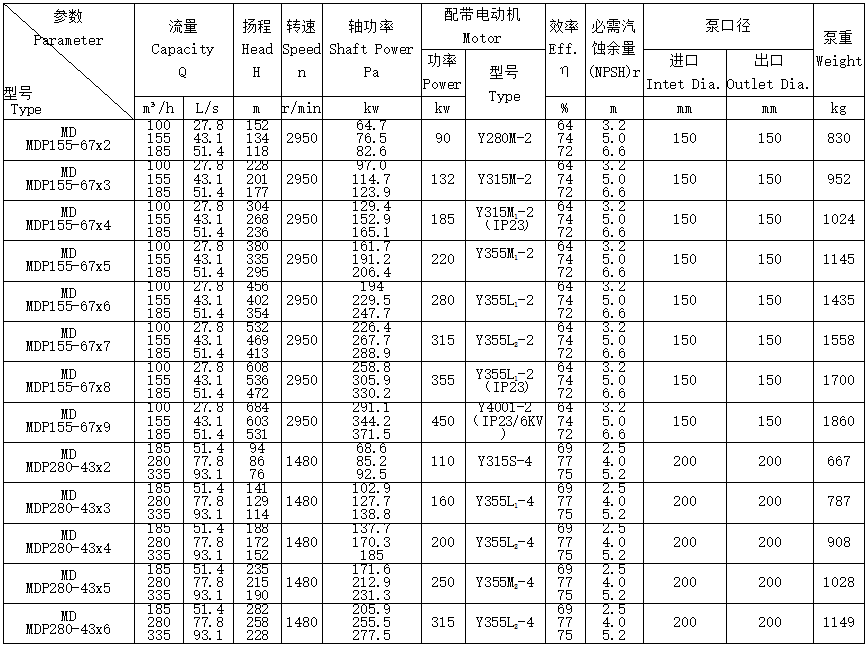

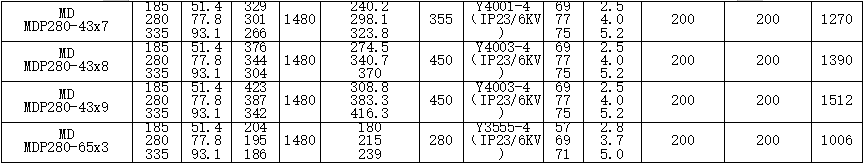

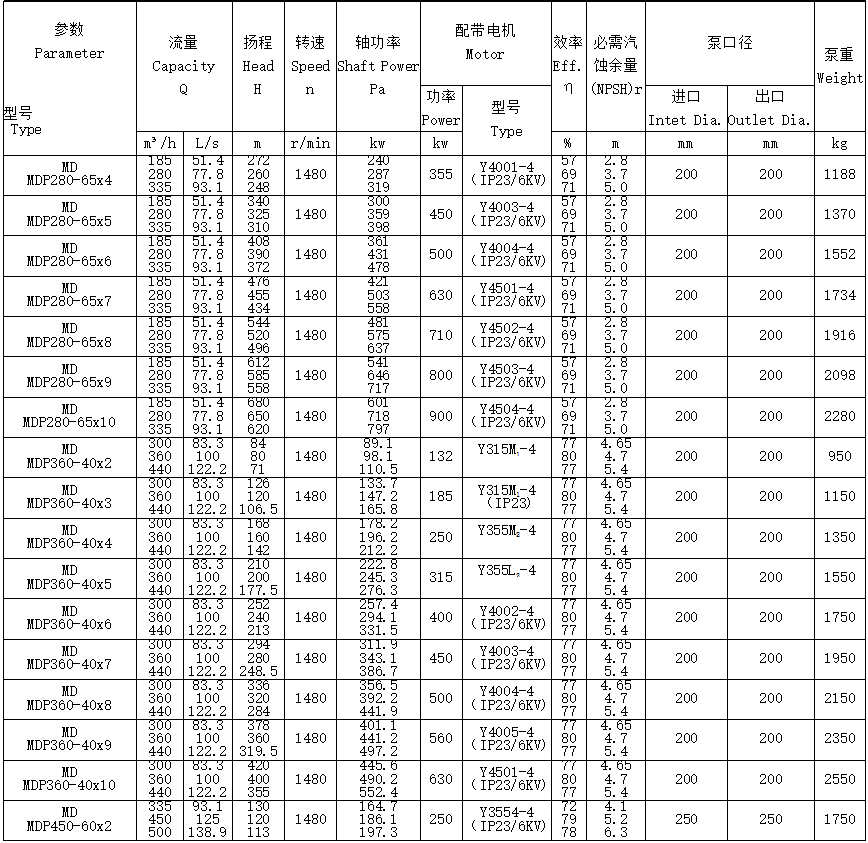

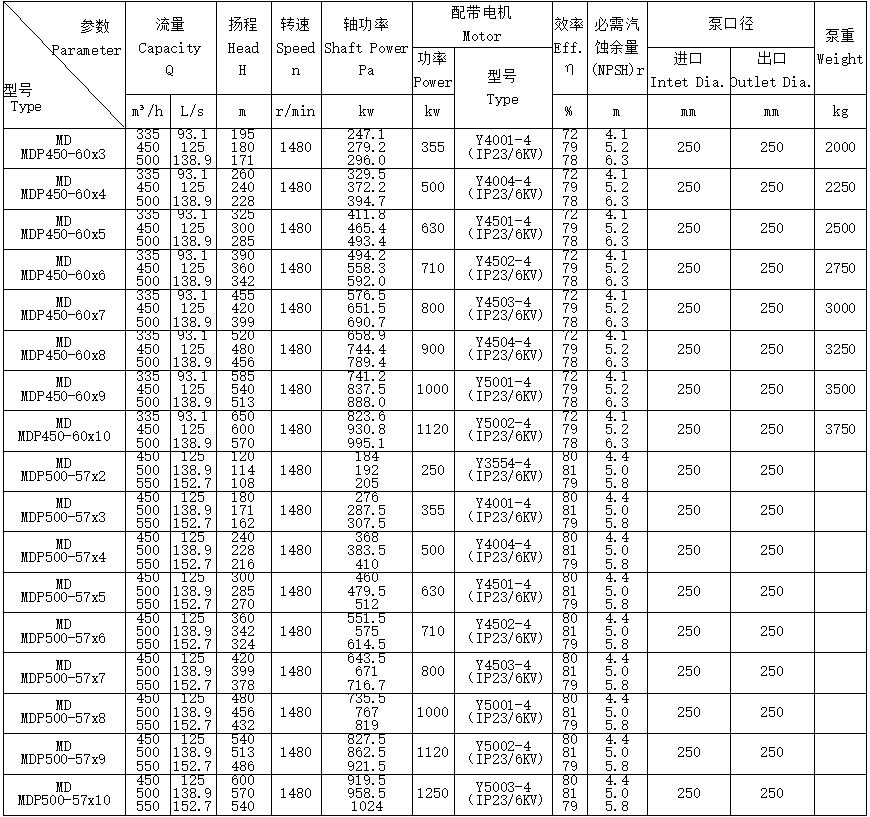

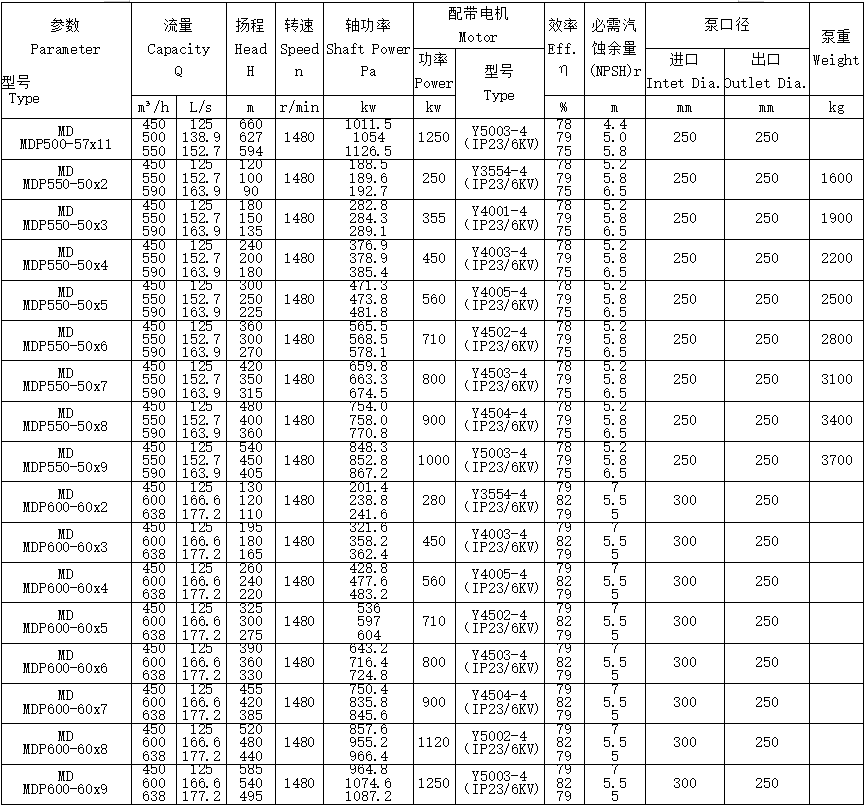

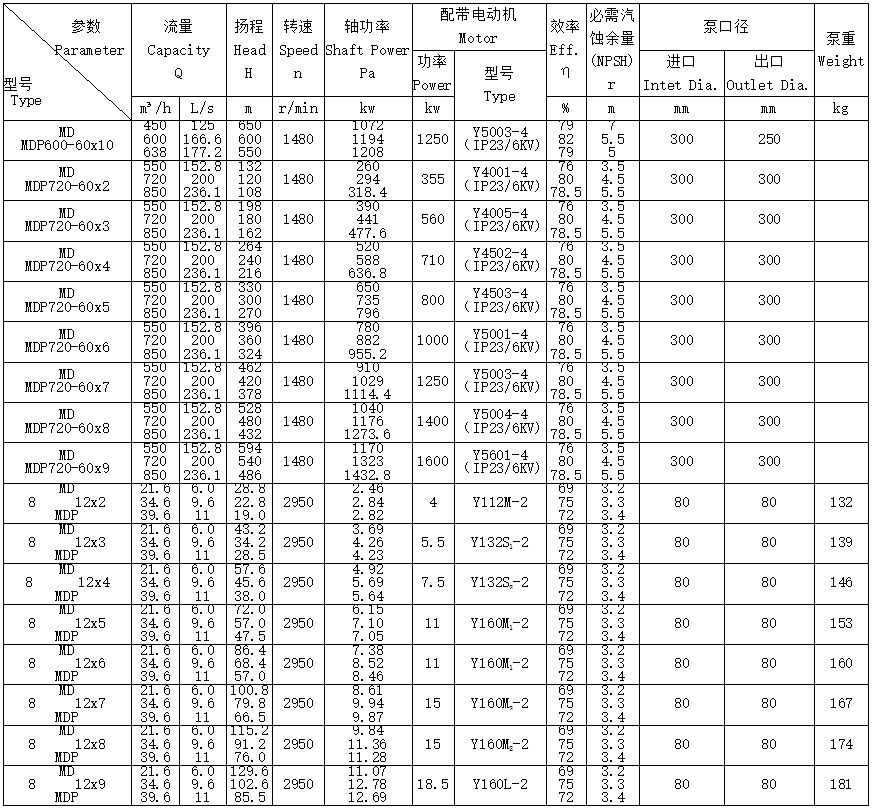

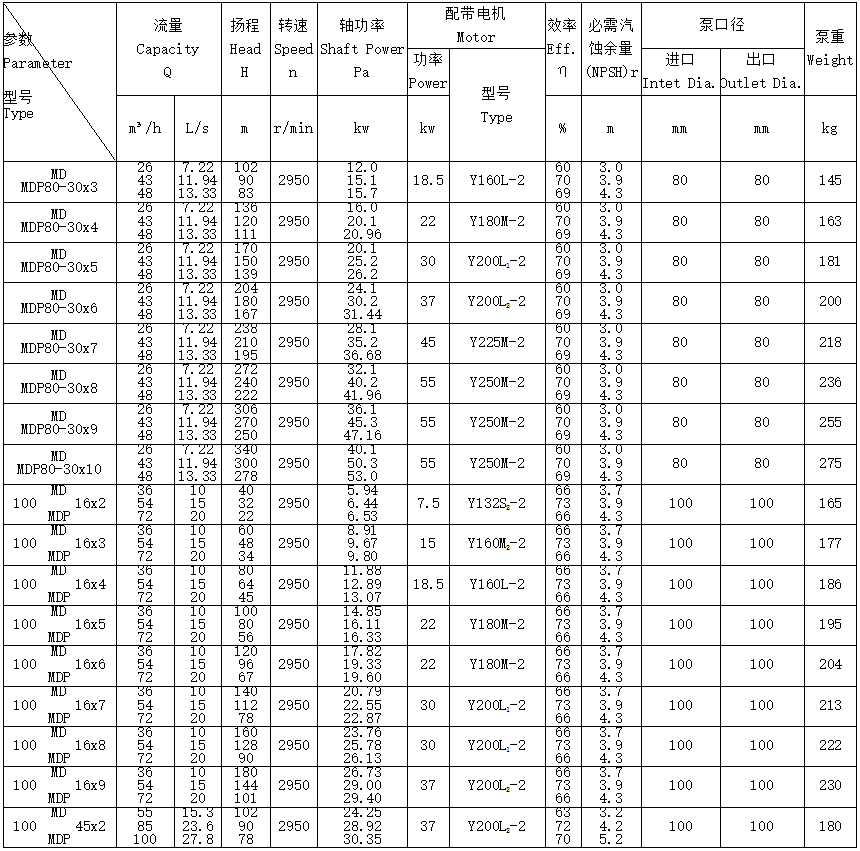

◎ performance range

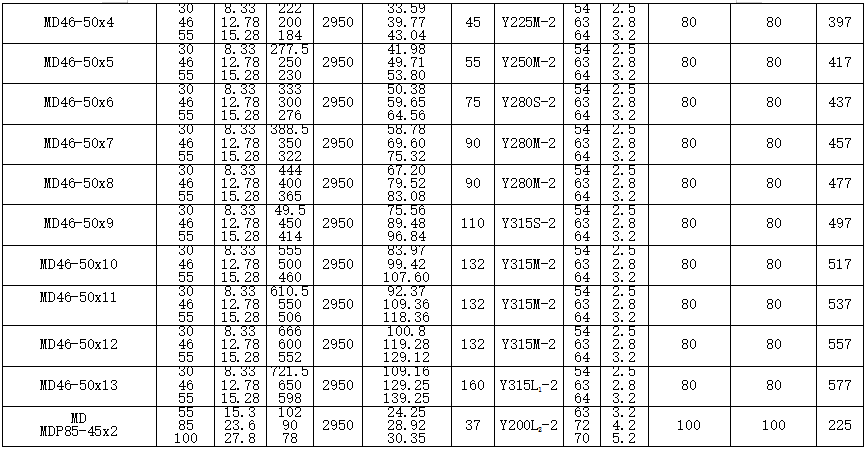

Flow: q = 3.75 - 840m3 / h

Lift: H = 19-684m

Diameter of pump suction and discharge ports: 40-300mm

MD (P) self balancing wear-resistant multistage centrifugal pump for coal mine

◎ product performance range and application range

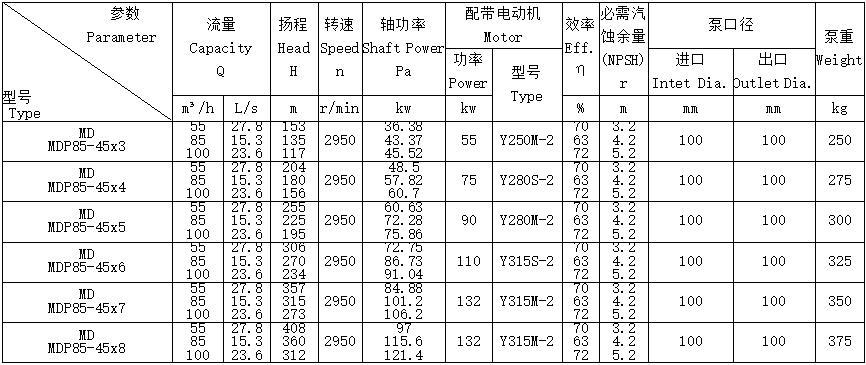

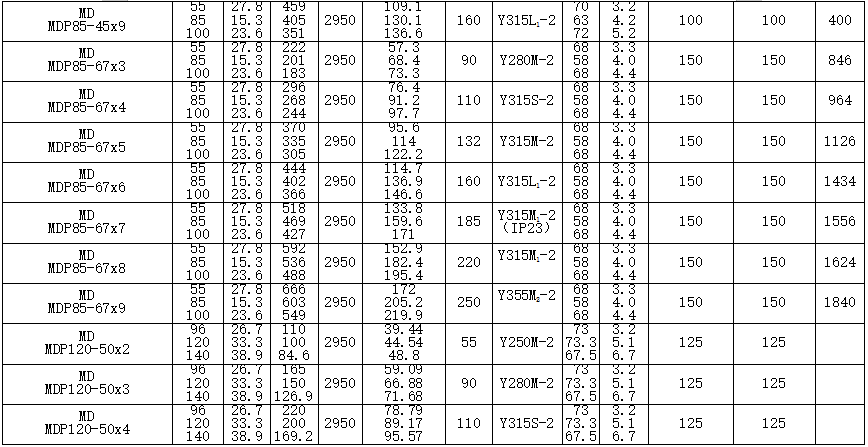

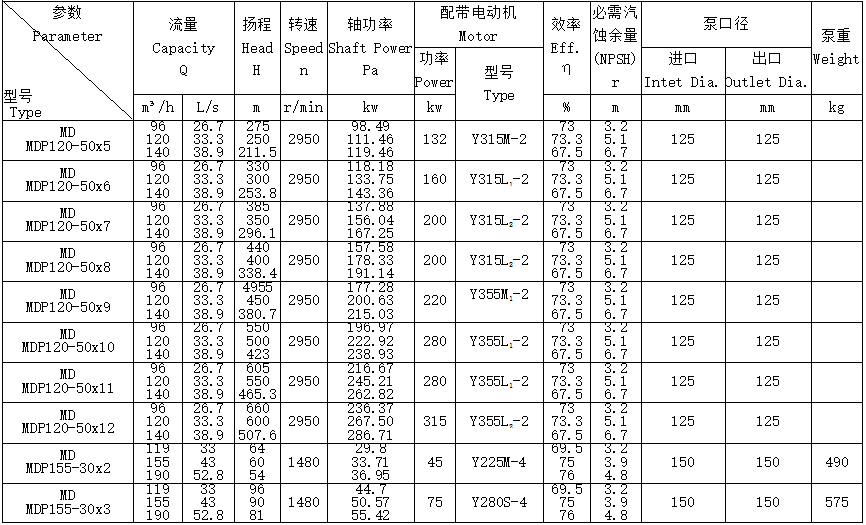

MD (P) self balancing wear-resistant multi-stage centrifugal pump for coal mine is a self balancing multi-stage centrifugal pump improved and designed by our company on the basis of MD wear-resistant multi-stage centrifugal pump. This series of pumps are efficient and energy-saving, wear-resistant and reliable, and have a long service life. They are especially suitable for mine drainage, pumping mine water and other similar liquids with a solid particle content of no more than 1.5% (particle diameter of less than 0.5mm), and a liquid temperature of no more than 80 ℃. Performance range: flow 85m3 / H ~ 580m3 / h, single-stage lift 30m ~ 93m.

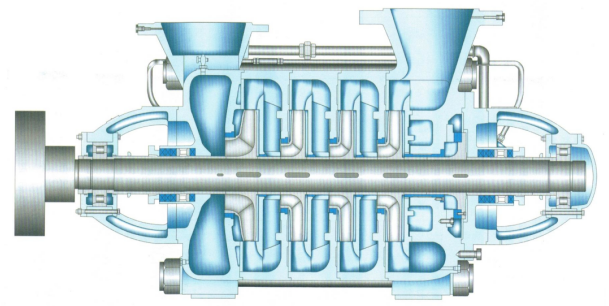

MD series pumps are horizontal, single suction and segmented multistage centrifugal pumps. The suction port is horizontal and the discharge port is vertical to the horizontal. The water inlet section, middle section, water outlet section, bearing body and other pump shell parts of the pump are connected together by tensioning bolts, and the number of stages of the pump is selected according to the lift of the pump.

The rotor of this series of pumps is mainly composed of the shaft and the impeller, shaft sleeve, balance disc and other parts installed on the shaft. The number of impellers is determined according to the number of stages of the pump. The parts on the shaft are fastened by flat keys and shaft nuts to be integrated with the shaft. The whole rotor is supported by rolling bearings or sliding bearings at both ends. The bearings are determined according to different models. They do not bear axial force, and the axial force is balanced by the balance disc. During the operation of the pump, the rotor is allowed to move axially in the pump casing, and centripetal ball bearings are not allowed. The rolling bearing is lubricated with grease, the sliding bearing is lubricated with thin oil, and the oil ring is used for self lubrication, and the circulating water is used for cooling.

The sealing surfaces between the water inlet section, middle section and water outlet section of the pump are sealed with molybdenum sulfide grease. Sealing rings and guide vane sleeves are installed between the rotor part and the fixed part for sealing. When the wear of the sealing rings and guide vane sleeves has affected the working performance of the pump, they should be replaced.

There are two types of shaft seals: mechanical seal and packing seal. When the pump adopts packing seal, the position of packing ring shall be placed correctly, the tightness of packing must be appropriate, and the liquid can seep out drop by drop. Various sealing elements of the pump are installed in the sealing cavity, and water with a certain pressure should pass through the cavity to play the role of water sealing, water cooling or water lubrication. A replaceable shaft sleeve is installed at the shaft seal to protect the pump shaft.

Viewed from the prime mover, the pump rotates clockwise.

In addition, the company can realize the multi outlet structure and function of this series of pumps according to the needs of users.

1. There is no fault in operation, and the overhaul period is long. The unique axial force balance mode and the "solid one traveling" bearing positioning effectively prevent the occurrence of mechanical friction and collision during operation, ensure no fault in operation, and increase the overhaul period.

2. The water pump has high efficiency and good energy saving effect. The new advanced sealing technology of the pump for nuclear industry has greatly reduced the leakage loss, improved the efficiency of the pump, and achieved advanced energy-saving effects.

3. Adopt new structure and integrate new technology. The symmetrical arrangement of impeller breaks through the traditional structure mode of water pump, and the unique throttling, pressure reducing device and balance structure design are more suitable for occasions with harsh media.

4. Low maintenance cost and long service life. The balance disc that is easy to wear and break down is eliminated, thus reducing the maintenance cost. The new materials, new processes and new structures adopted ensure the service life and reliability of the operation.

MD mining wear-resistant multistage pump

Hundreds of customers to choose from