7 * 24-hour service hotline

+86 15836191545

summary

CZ series standard chemical pump is a horizontal, single-stage, single suction centrifugal pump; Its size and performance comply with DIN24256/ISO2858 standard.

The performance range of CZ series standardized pumps covers all the performances of IH series standardized pumps. Its efficiency, cavitation performance and other indicators exceed IH type pumps, which can be interchanged with IH type pumps.

It is used to transport low temperature or dangerous liquid, neutral or corrosive liquid, clean or solid particles. It is especially suitable for chemical and petrochemical industries, oil refineries, paper mills, pulp industries and grain industries.

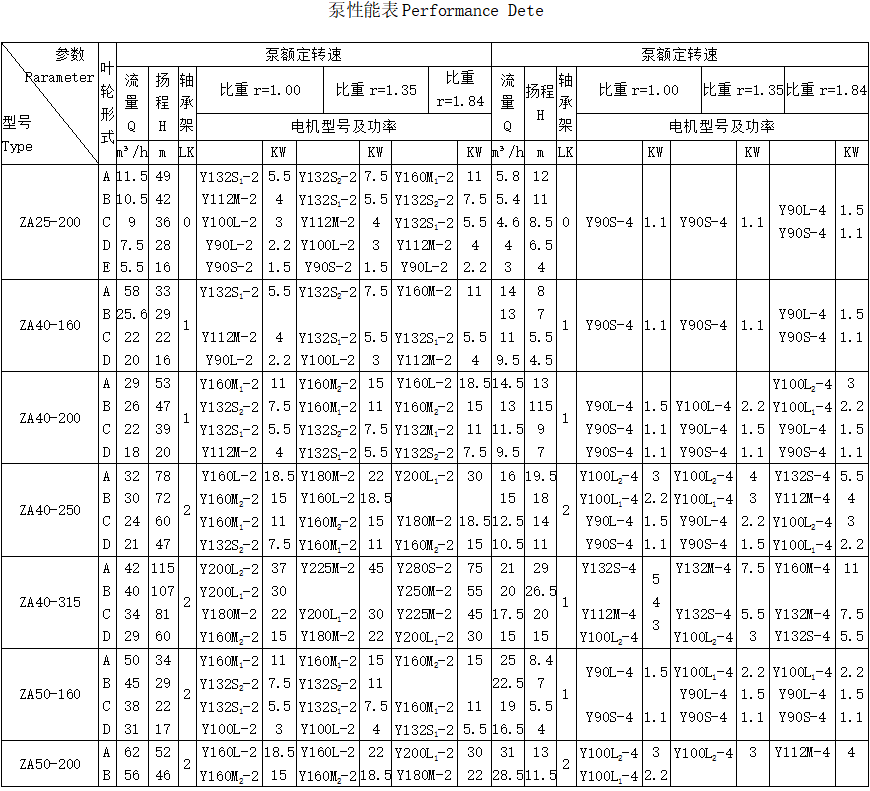

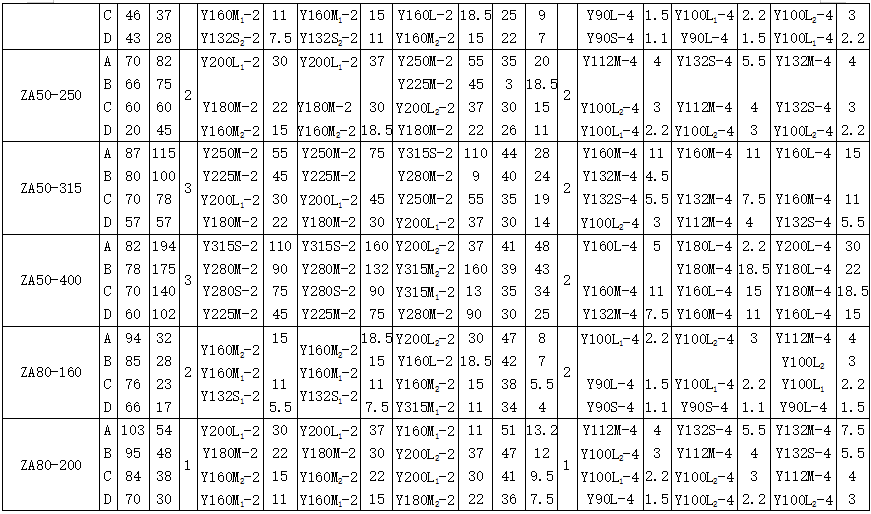

ZA and ZAO petrochemical process pumps are designed according to AP1610 and VDMA24297 (light/medium) specifications of the Branch.

This pump is suitable for conveying clean or granular liquid, low or high temperature liquid, neutral or corrosive liquid. Mainly used in grain and oil plants, petrochemical industry, coal processing industry and low-temperature engineering; Chemical industry, paper making, pulp industry, sugar industry and general process industry; Water supply industry and seawater desalination plant; Heating and air conditioning systems; power plant; Environmental protection engineering; Ship and marine industry, etc.

Model description

CZ(ZA)500-200

CA (ZA) - Standard Chemical Pump (Petrochemical Process Pump)

50 - Pump outlet diameter 50mm

200 - nominal diameter of impeller: 200mm

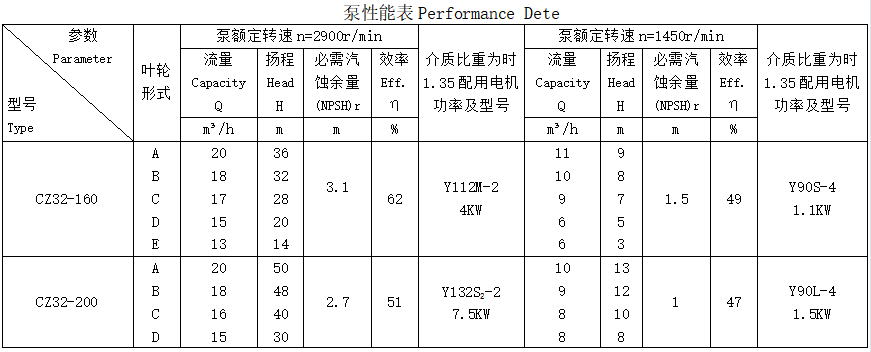

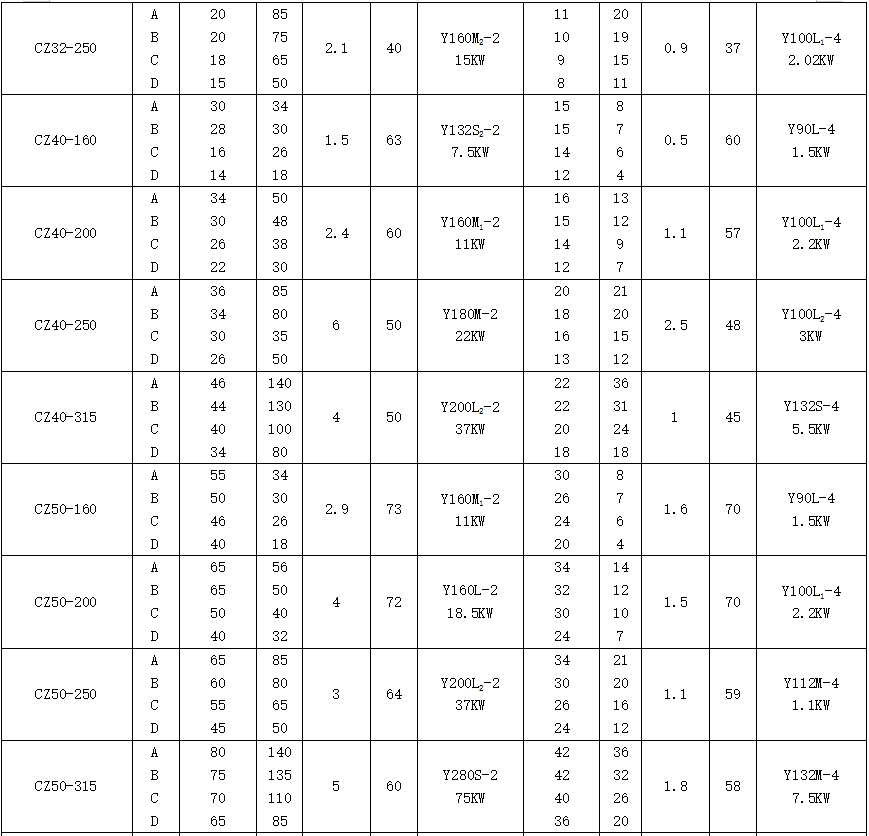

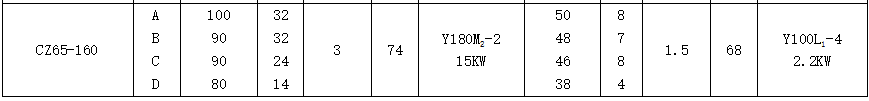

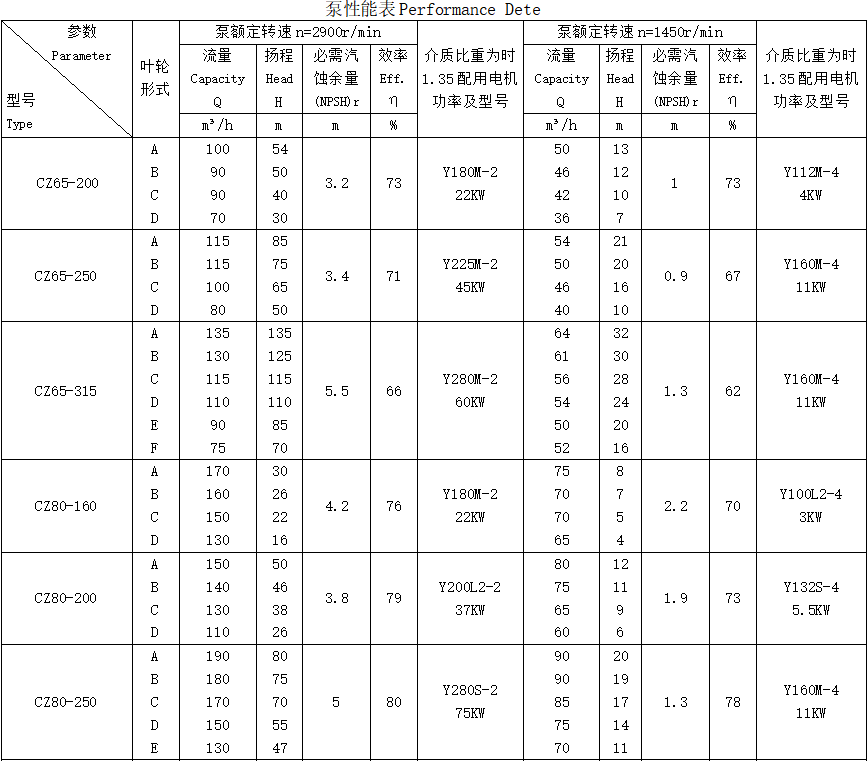

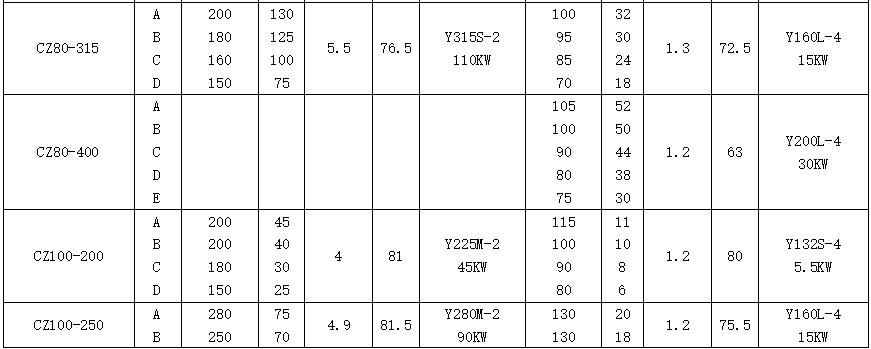

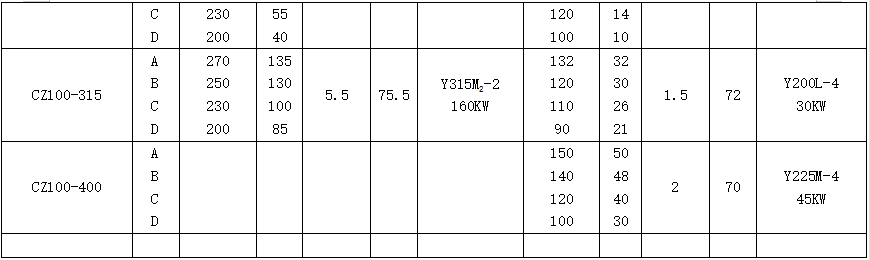

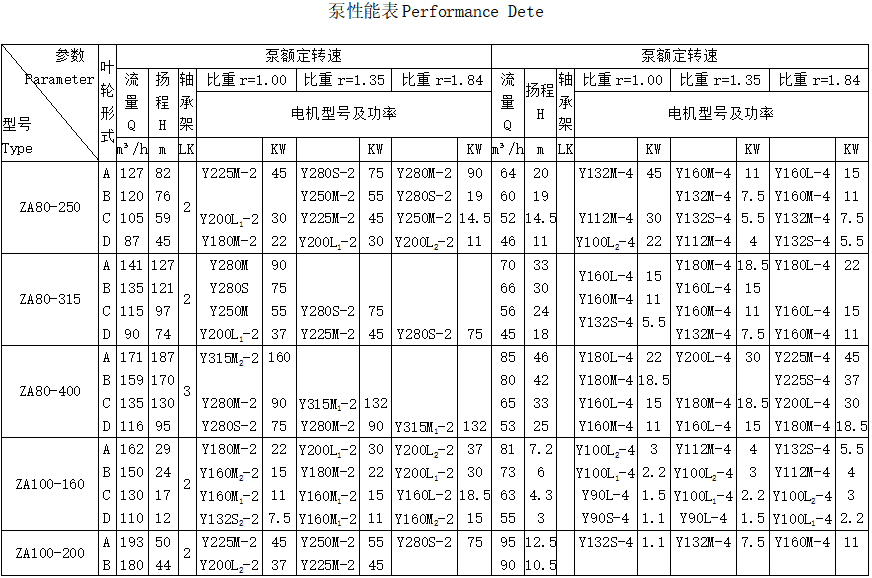

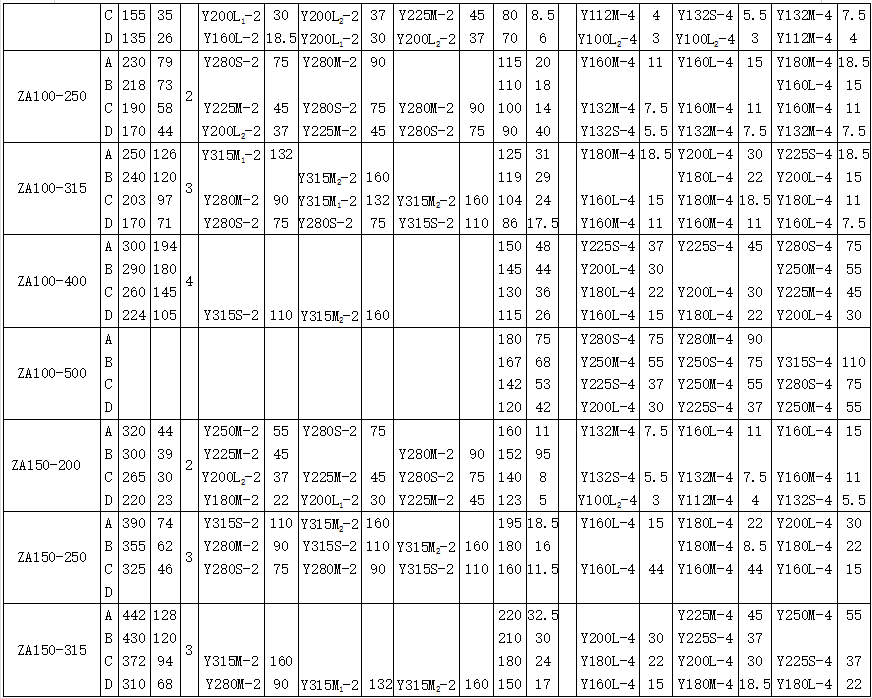

Performance range

CZ series ZA, ZAO series

Flow: Q=3.2~200m ³/ H Diameter: 25~400mm

Lift: H=7~160m Flow: Q=0~2600m ³/ h

Working pressure: P=2.5MPa Lift: H=0~250m

Working temperature: T=- 80 ℃~300 ℃ Working pressure: P=2.5MPa

Operating temperature: T=- 20~180 ℃

Center support: T=- 20~450 ℃

The pressure acting on the shaft seal is balanced by the balance hole on the auxiliary blade or impeller. The shaft seal can be either a soft packing seal (which can be cooled or not) or a single or double end non-equilibrium mechanical seal of various structures. The ball bearing is durable and the shaft diameter is sufficient to ensure smooth operation. The pump body of some specifications is designed as a double screw shell to balance the radial force. The bearing frame, including shaft, impeller, stuffing box, etc., forms a combined part, so that the pump body does not need to be removed from the pipe during maintenance (if the extended coupling is used, the motor does not need to be removed). The flange design adopts PN16 and PN25 (according to the difference of materials). Also, it can be used for ANS125 lbs/150 psi.

Hundreds of customers to choose from