The piping and flange connection dimensions of this series of electric pumps are manufactured according to GB/T9113 and PNO 6Mpa size, compact structure, especially the low-speed sewage pump runs more stably and reliably. The built-in high-quality mechanical seal can effectively block the pumped medium out, prevent water from entering the motor cavity, and the pump shaft treated by special process can effectively prevent and mitigate corrosion. High configuration and high process requirements comprehensively ensure the long-term reliable operation of the motor. This series of electric pumps are especially suitable for the discharge of sewage and sewage in urban drainage, municipal sewage treatment, building construction, mining, municipal environmental protection and other places. It is an ideal water conveyance equipment for pumping mud, mortar, domestic wastewater, sewage excrement, solid particles containing fiber, paper scraps, farmland irrigation, lotus pond dredging and other occasions.

Thermal control switch is embedded in the stator of high-power electric pump. It is "normally closed" at normal temperature. When the stator temperature reaches 125 ℃, the switch is opened. When wiring is installed, two "motor temperature rise signal lines" are connected in series to the stop button of the control cabinet. A water leakage probe is installed in the oil chamber for water leakage detection It is connected with any line in the power line to the leakage circuit breaker. When the mechanical seal at the pump side leaks and the oil-water ratio in the oil chamber reaches a certain concentration, the oil-water probe will send out an alarm signal (the indicator light is on)

And automatically cut off the power supply to stop the pump. The maintenance personnel shall timely replace the oil in the oil chamber, and check and replace the mechanical seal at the pump side.

Float switch: when the mechanical seal at the motor side leaks, liquid enters the float switch chamber, and the liquid infiltrates to a certain height, the float

The switch will give an alarm signal (the indicator light is on) and stop the pump. The maintenance personnel should repair and replace the mechanical seal at the motor side.

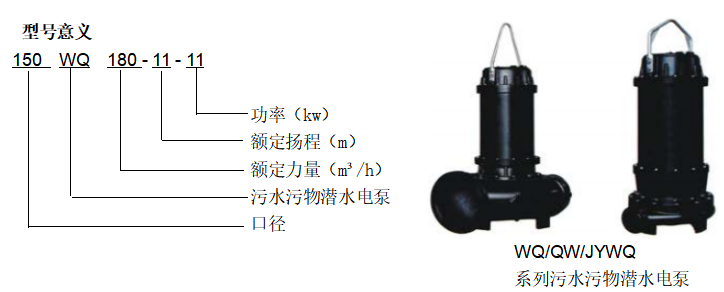

Product Overview

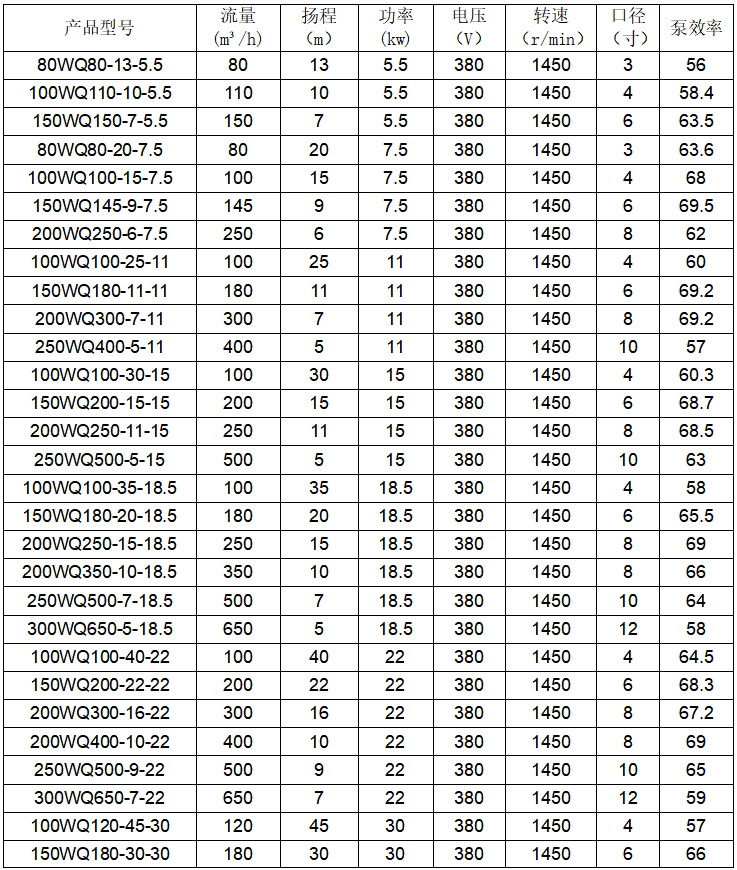

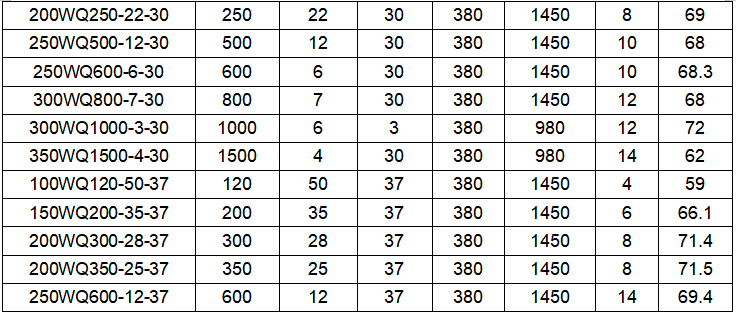

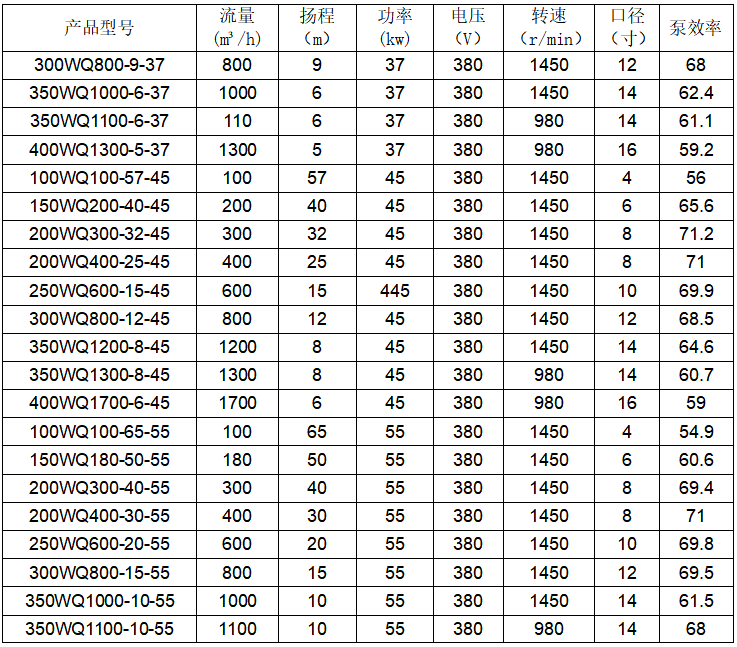

WQ series sewage submersible electric pump (hereinafter referred to as electric pump) consists of water pump, seal and motor. The motor is located on the upper part of the electric pump and is divided into single phase and three-phase asynchronous motors. Double end mechanical seal is used between water pump and motor, and "O" type oil resistant rubber seal ring is used as static seal at each fixed lip seal. This series of electric pump has the characteristics of compact structure, large flow, high efficiency, convenient use, etc. The mechanical seal of key parts is made of hard alloy and high-quality silicon carbide, which has the characteristics of good corrosion prevention, leakage prevention, durability, etc.

Main purpose

This series of electric pumps are widely used in municipal sewage treatment, construction engineering, hotels, miners, ponds, printing and dyeing, paper making, textile and other places. It is an ideal equipment for pumping mud, mortar, domestic waste water, sewage, feces and solid particles containing fibers, paper scraps, etc

Hundreds of customers to choose from