7 * 24-hour service hotline

+86 15836191545

BQS Series Mine Flameproof Submersible Pump for Sewage and Sand Discharge

BQS series mine explosion-proof sewage and sand discharge submersible pump is an efficient, energy-saving, "down suction" explosion-proof mine floor water and sand discharge submersible pump designed and developed according to the explosion-proof standard MT/T671-2005 Flameproof Submersible Pump for Coal Mines. It has the advantages of safety, reliability, portability, practicality, good sewage and sand discharge performance, long service life, reasonable type spectrum, convenient selection, durable double-sided seal, safety, reliability and strong adaptability

• Flow: 100-2500 m ³/ h

• Lift: 7-700m

• Power: 2.2-315kw

• Efficiency: 28.9-68.5%

Product Overview

BQS series mine explosion-proof sewage and sand discharge submersible electric pump is a high-efficiency, energy-saving, "down suction" explosion-proof mine floor water and sand discharge electric pump designed and developed in accordance with the explosion-proof standard MT/T671-2005 Flameproof Submersible Pump for Coal Mines. Aiming at the characteristics of large amount of coal slime in the coal mine, it has solved the problems of product structure, parameter optimization, manufacturing process, operating efficiency, sealing and leakage prevention of the submersible electric pump for sewage and sand discharge Compared with similar domestic products, the key technical problems in material application have the advantages of safety, reliability, portability and practicality, good sewage and sand discharge performance, long service life, reasonable type spectrum, convenient selection, durable double-sided sealing, safety, reliability and strong adaptability, as well as excellent explosion-proof structure performance and higher protection grade, which are suitable for explosive gas environments containing methane or coal dust Places such as underground mining faces and roadways with explosion risk are used together with water pumps.

BQS submersible electric pump for mine sewage and sand discharge has complete specifications, with power range from 2.2kW to 315kW and flow range from 10m ³/ H to 2500m ³/ h. The lift range is from 7m to 700m. All products have full lift and no overload. One machine can be used for multiple purposes, providing users with great convenience and saving more than 10% of energy. In order to make the pump operate with or without water, we have designed this product as a sandwich strong cooling structure, so our series of submersible electric pumps can fully meet the use of coal mines.

performance parameter

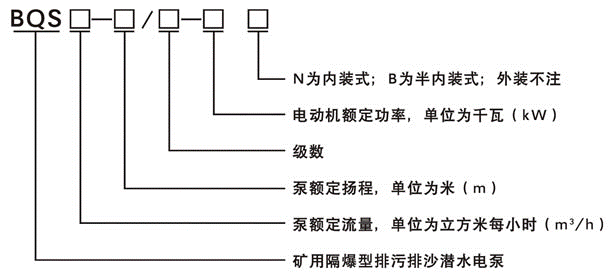

Model Meaning of BQS Series Mine Flameproof Submersible Pump for Sewage and Sand Discharge

Main Application and Service Conditions of BQS Series Mine Flameproof Submersible Pump for Sewage and Sand Discharge

Main purpose:

The submersible electric pump for mine sewage and sediment discharge is an advanced and reliable drainage tool that can be used in working faces, roadways, water pockets at the bottom of the well, local ponding pits, coal preparation plant drainage, engineering drainage and other occasions. It is applicable to places with methane (commonly known as gas) and coal dust explosion hazards in the coal mine, and transport mixed sewage containing sediment, coal slime, coal gangue, coal cinder, fiber and other insoluble solids. It can also be used in buildings, hospitals, residential quarters, municipal works, road traffic and its construction, factory sewage discharge, small sewage treatment and other occasions to discharge wastewater, rainwater and sewage containing solid particles and long fibers.

Service conditions:

1. Power supply 380V or 660V or 1140V, three-phase, 50HZ.

2. The medium temperature generally does not exceed 40 ℃, the PH value is 5-9, and the medium weight is ≤ 11kN/m ³

3. The diameter of solids in the medium shall comply with the provisions of MT/T 671-2005. Please remind when ordering for special requirements.

Structural Features and Description of BQS Series Mine Flameproof Submersible Pump for Sewage and Sand Discharge

Structural features:

1. Model screening.

2. Mechanical seal improvement: independent series mechanical seal and double end mechanical seal are adopted.

3. Structural optimization: the structural design is conducive to the sealing performance of the mechanical seal. I operates stably, has higher reliability, and is more portable and practical, with low energy consumption. It can operate without water for a long time.

4. IPX88 motor protection grade: submersible motor has good cooling effect, lower temperature rise than ordinary motor, and its durability is further improved. Class F insulation makes the motor have a longer service life.

Structure description:

The overall structure of the pump is vertical, submersible, mechanical and electrical integration, suction type, which can drain the shallow water on the surface of the working face. The product is mainly composed of overcurrent components and motors. The structure of the electric pump can be divided into externally mounted, internally mounted and semi internally mounted according to the discharge mode of the liquid flow.

1. Pump body and impeller: On the basis of actual measurement and test, carefully select and match the pump body and impeller, so that there is no blockage, high flow capacity, high efficiency, flat power curve and no overload. The impeller has accurate balance, small vibration and stable operation.

2. Motor: specially designed submersible motor, IPx8 protection, Class F insulation allows temperature rise, under normal temperature rise conditions, the motor insulation life is extended, while the submersible cooling effect is good, the actual temperature rise is low, and the motor insulation life

3. Machine cooling: (1) Externally mounted electric pump: the heat of the motor is dissipated through the casing. As long as the medium submerges half of the motor stator casing, the pump can operate reliably and safely. The more submerged, the better the motor cooling. (2) Built in electricity

Sand discharging submersible pump adopts sandwich strong cooling structure. Even if the motor is idling, the temperature rise of the motor can be controlled below 40 ° C, greatly improving the service life of the whole machine. It is suitable for places with shallow water level. The product can be idling for a long time without water, and can be used in an unattended environment, reducing labor costs.

4. Shaft seal: the motor shaft seal adopts two independent mechanical seals in series to form two reliable sealing lines. The channel is in the medium in the pump, and the sealing surface is pressed more tightly with the increase of medium pressure to effectively prevent water from entering the oil chamber. The second channel is in the oil chamber to prevent oil from entering the motor. If the channel fails (its working conditions are worse than the second channel), the second channel can still prevent oil and water from entering the motor. The bellows type mechanical seal and the innovative structural cavity further improve the reliability of the shaft seal. Under normal use, the trouble free operation time exceeds 2000h.

5. Oil chamber: it is a barrier to prevent the medium from entering the motor from the pump shaft, preventing the medium from penetrating into the motor. If the mechanical seal leaks, the buffer medium from the oil chamber cannot directly enter the motor. At the same time, the friction surfaces of two independent mechanical seals are lubricated and cooled to make the mechanical seal work reliably. In addition, it can also take away the heat of the lower bearing and some heat of the motor.

6. Bearing: The double row angular contact bearing at the lower part has a strong bearing capacity. It forms a reliable support for the motor pump shaft with the upper deep groove bearing. It has a large bearing margin for the radial, axial and other forces generated when the pump is working to ensure the stable operation and long service life of the unit.

7. Cable and its sealing: (1) MT818.5-2009 flame-retardant cable for coal mine is used as the cable. The cable core section is designed for long-term reliable operation under 40C ambient temperature and full load power of the motor. If the motor operates under non full load power or under 40C ambient power, its service life will be longer. (2) There is a seal between the cable rubber sleeve and the motor gland to prevent the medium from seeping into the motor cavity from the interface between the cable and the motor cover.

8. Motor shell: the motor shell is composed of the casing, upper end cover, lower end cover, etc. The connection and fitting of all parts are provided with reliable static seals. Each set is checked by strict hydrostatic test to ensure no leakage.

9. Special handle: special handle is provided for easy handling. Do not use the cable as a handle during handling.

The external sewage submersible pump is designed as a down pump structure. The water outlet is located at the lower part of the whole machine, and the water is directly discharged from the pump body through the water outlet. The motor power of this type of pump is generally below 22KW, which is a single-stage single suction small pump. Its remarkable characteristics are simple structure, light and practical, and strong pollution removal capacity, and it is suitable for use in places with more impurities, coal sludge, and gravel in the water.

The integral structure of the built-in submersible sand pump is designed to be vertical and lower pump type, and the built-in motor structure is adopted. The motor shell is provided with interlayer. During normal drainage, the water delivered by the pump flows through the interlayer and flows out from the top to realize motor water cooling; Even if the water is cut off, there is still water to cool the motor in the interlayer outside the motor to ensure that the motor will not be burnt out due to overheating. No special person is required to take care of it, which greatly reduces the labor cost. Most of the single-stage and multi-stage pumps in our company adopt the built-in structure.

BQS semi enclosed submersible pump for mine sand drainage takes into account the advantages of both the built-in pump and the external pump, which is relatively portable, and also ensures that the motor will not have problems in cooling after the water is cut off.

Hundreds of customers to choose from