7 * 24-hour service hotline

+86 15836191545

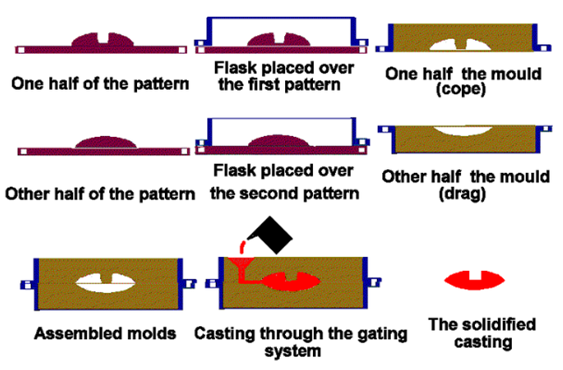

· Sand casting refers to the casting method of producing castings in sand mold. Steel, iron and most non-ferrous alloy castings can be obtained by sand casting. Because the molding material used in sand casting is cheap and easy to obtain, the casting mold is easy to manufacture, and it can adapt to the single piece production, batch production and mass production of castings, it has been the basic technology in casting production for a long time.

· The introduction of sand mold

·

· The basic raw materials for making sand mold are casting sand and sand binder. The most commonly used casting sand is siliceous sand. The high temperature performance of silica sand can not meet the requirements of the use of zirconium sand, chromite sand, corundum sand and other special sand. In order to make the sand mold and core have a certain strength, in the handling, molding and pouring of liquid metal will not be deformed or damaged, generally in the casting to add sand binder, the loose sand bonded together to become sand. The most widely used sand binder is clay, can also be used a variety of dry oil or semi-dry oil, water-soluble silicate or phosphate and various synthetic resins for sand binder. The outer sand mold used in sand casting can be divided into three types: wet clay sand mold, dry clay sand mold and chemically hardened sand mold according to the binder used in sand mold and the way of building strength.

Sand core type

In order to ensure the quality of the casting, the cores used in sand casting are generally dry cores. According to the different binder used in the core, the core can be divided into clay sand core, oil sand core and resin sand core.

Clay sand core:A simple core made of clay sand.

Oil sand core:The core made of core sand with dry oil or semi-dry oil as binder is widely used. The viscosity of oil is low, the fluidity of mixed core sand is good, and it is easy to tighten when making core. But just made of the core strength is very low, generally to use a copy of the core board to undertake, and then in the oven at 200 ~ 300℃ for several hours, by air will be oil oxidation and hardening. The disadvantages of this method are: the core is easy to deform in the process of demoulding, handling and baking, which leads to the reduction of the dimensional accuracy of the casting; It takes a long time to bake and uses a lot of energy.

Resin sand core:A variety of cores made of resin sand. The core is hardened in the core box and then removed to ensure the tolerance of the shape and size of the core. According to different hardening methods, the manufacturing of resin sand core is generally divided into three methods: hot core box core making, shell core making and cold core box core making.

· HNYB Sand Casting Advantage

·

· Sand casting is a kind of casting process, HNYB sand casting used in the casting mold is generally composed of the external sand mold and the core. Because the molding material used in sand casting is cheap and easy to obtain, the casting mold is easy to manufacture, and it can adapt to the single piece production, batch production and mass production of castings, it has been the basic technology in casting production for a long time. At present, in the world, in the total casting production, 60 ~ 70% of the casting is produced with sand, and 70% of them are produced with clay sand. HNYB sand casting has lower cost, simpler production process and shorter production cycle than other casting methods. So castings such as the engine cylinder block, cylinder head and crankshaft of automobiles are produced by the clay wet sand process. When the wet type cannot meet the requirements, consider the use of clay sand surface dry sand, dry sand or other sand. The weight of HNYB clay wet sand casting can range from a few kilograms to tens of kilograms, while the weight of dry clay casting can reach tens of tons.

Hundreds of customers to choose from