7 * 24-hour service hotline

+86 15836191545

summary

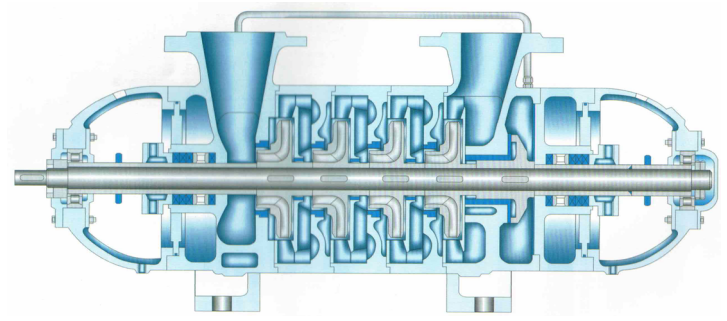

This series of pumps is a horizontal single suction multi-stage segmented centrifugal pump, which can be used to transport clean water or liquids with physical and chemical properties similar to clean water. It is suitable for water supply of medium and low pressure boilers or sub high pressure boilers, as well as high pressure water supply and drainage of factories or cities. The temperature of transmission medium is - 20 ℃ - 150 ℃, and the allowable inlet pressure is less than 0.6MPa.

This series of pumps adopts the hydraulic mode of high-efficiency energy-saving products recommended by the state. The utility model has the advantages of high efficiency, wide performance range, safe and stable operation, low noise, long service life, convenient installation and maintenance, etc.

Our company has passed the ISO9001: 2000 quality system certification. The product design, production and service have a strict and standardized control system, and the product quality is fully guaranteed.

Model description

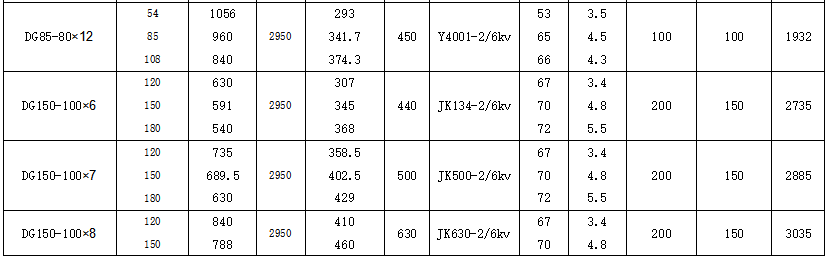

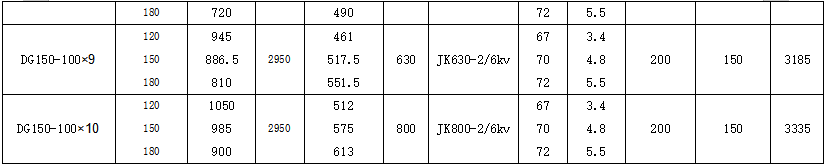

Example: DG85-80x12

DG multistage boiler feed pump

85 - Flow at design point is 80mm ³/ h

80 - Single stage lift at design point is 80m

12 - 1 2 stages

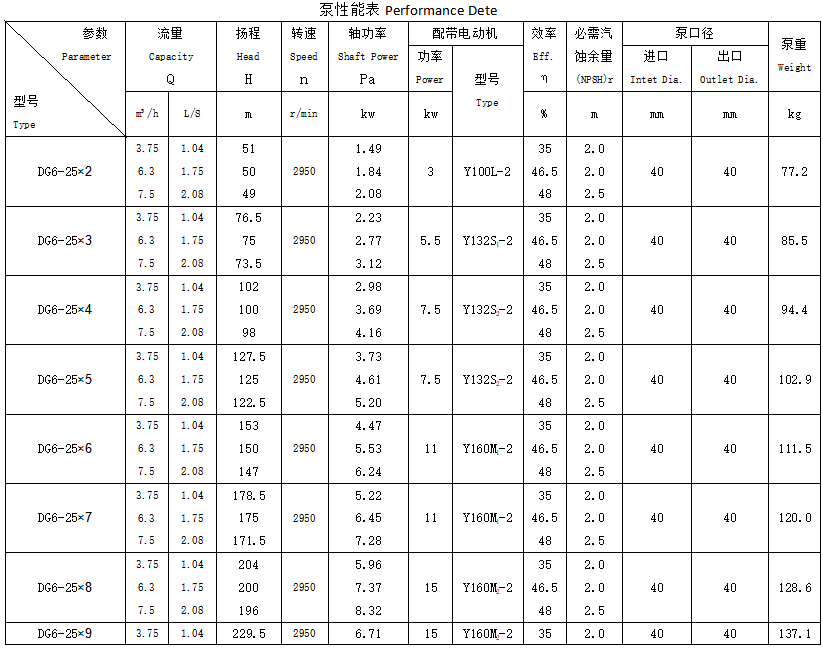

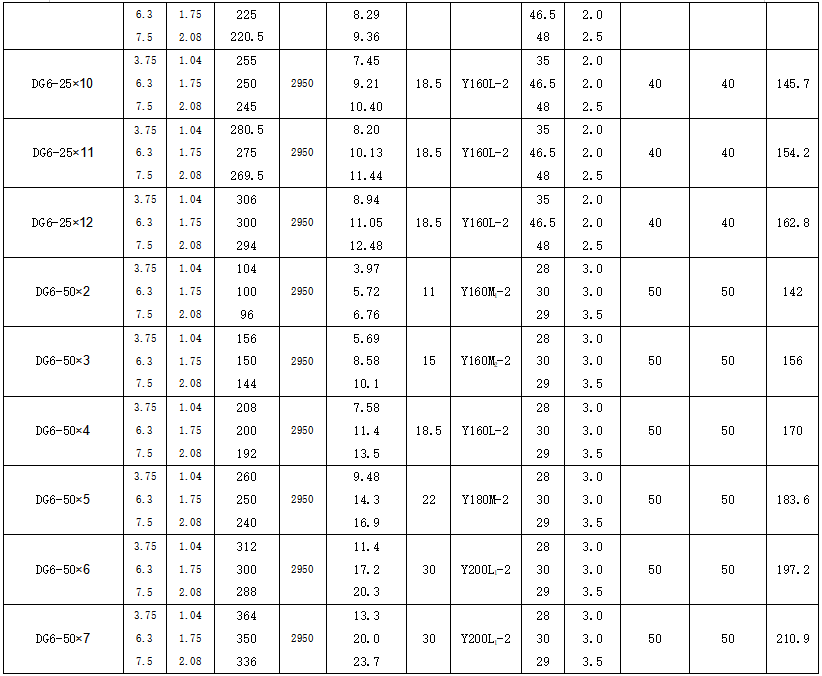

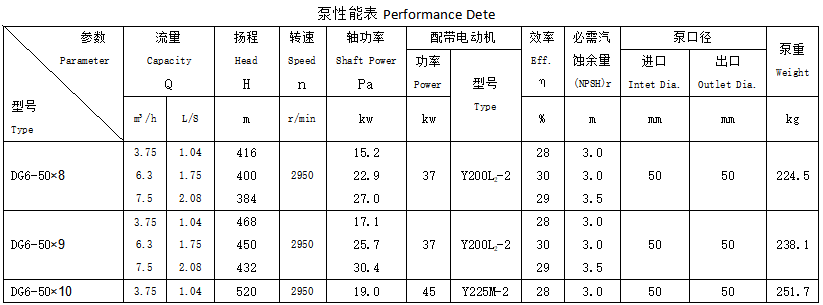

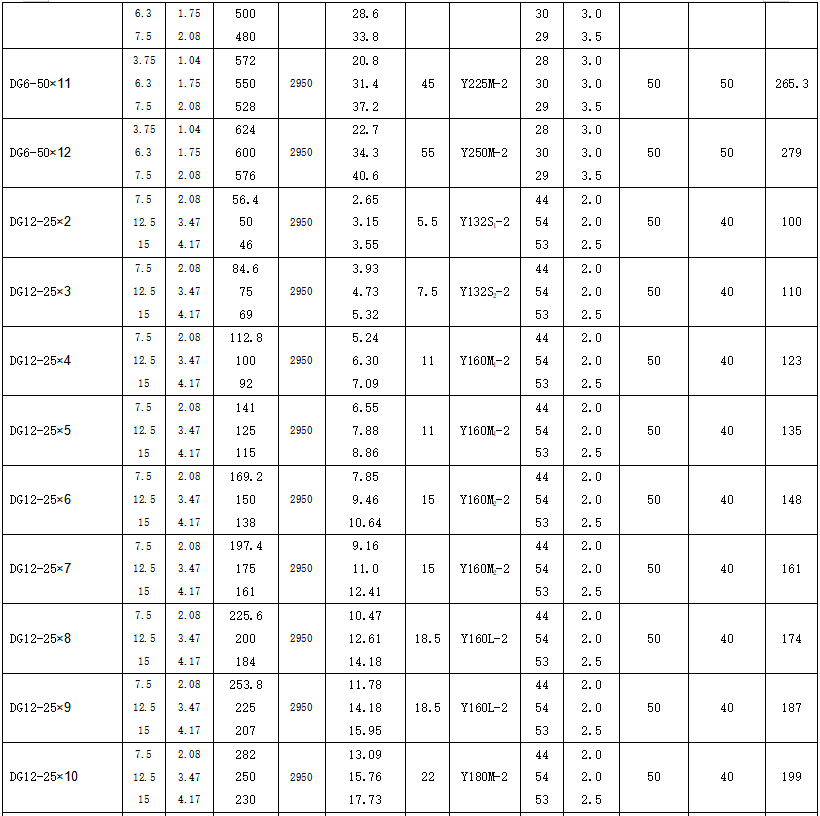

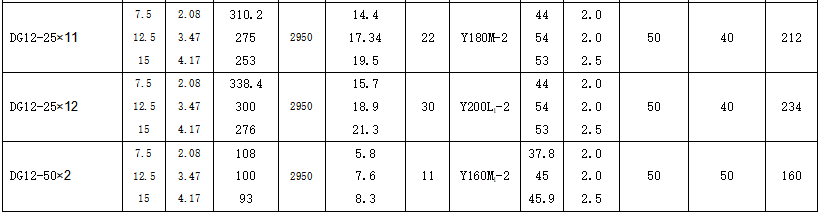

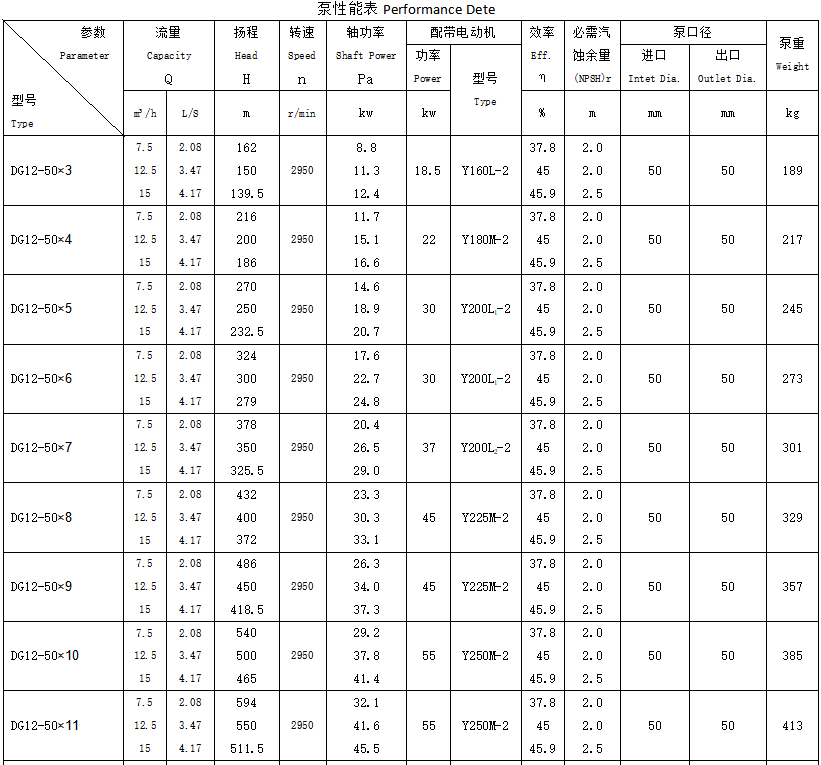

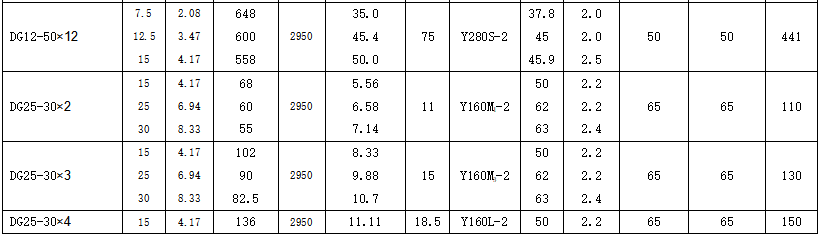

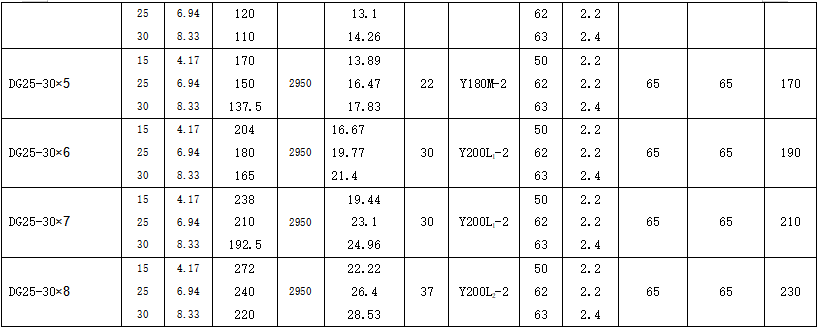

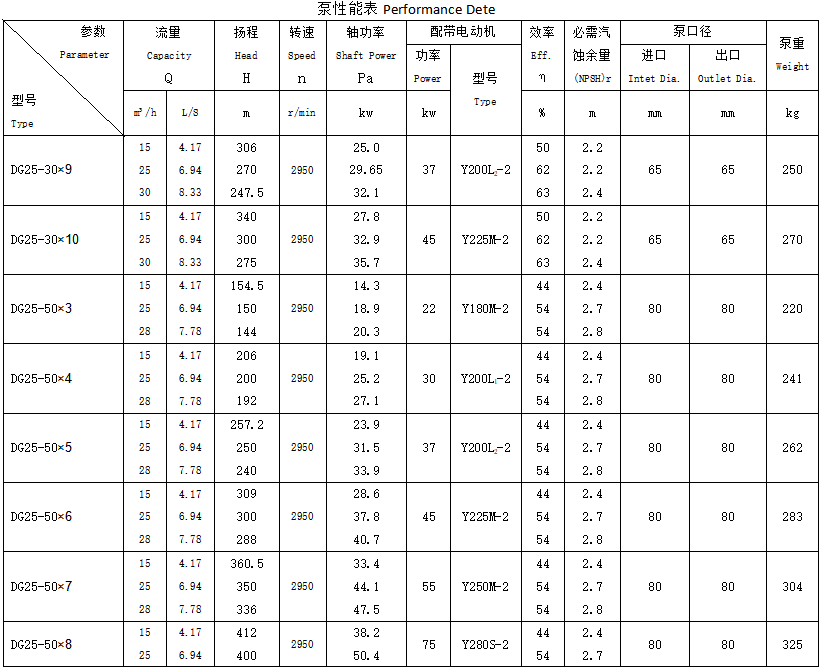

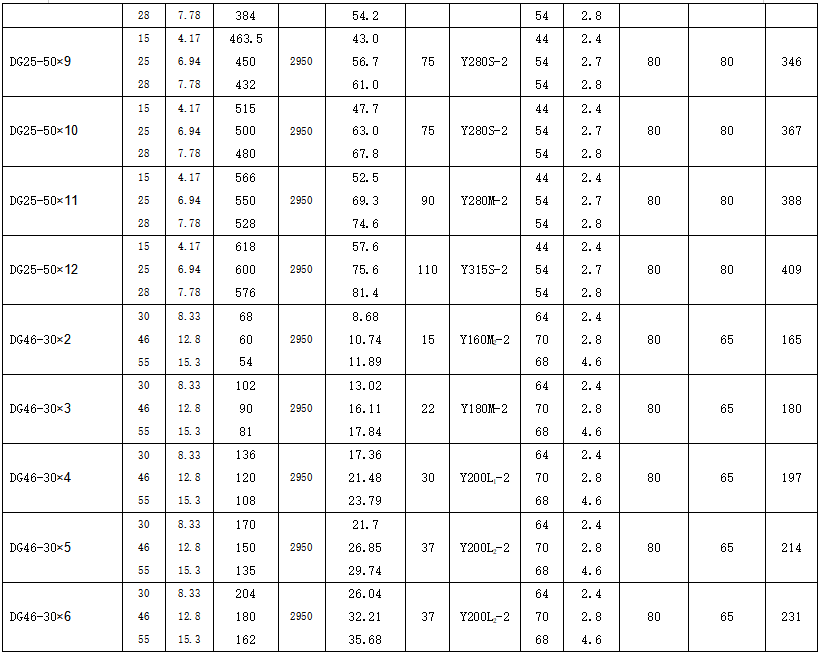

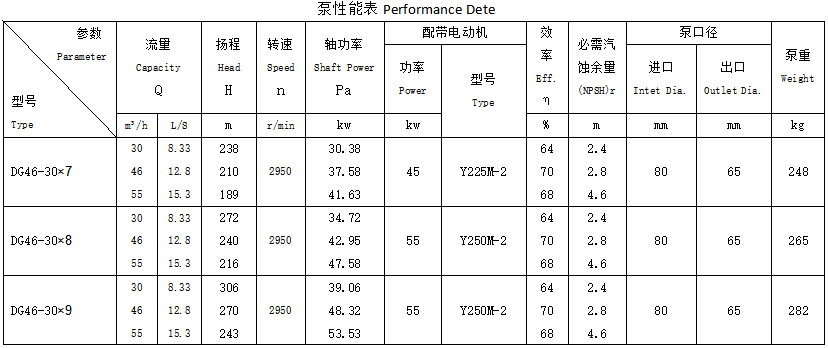

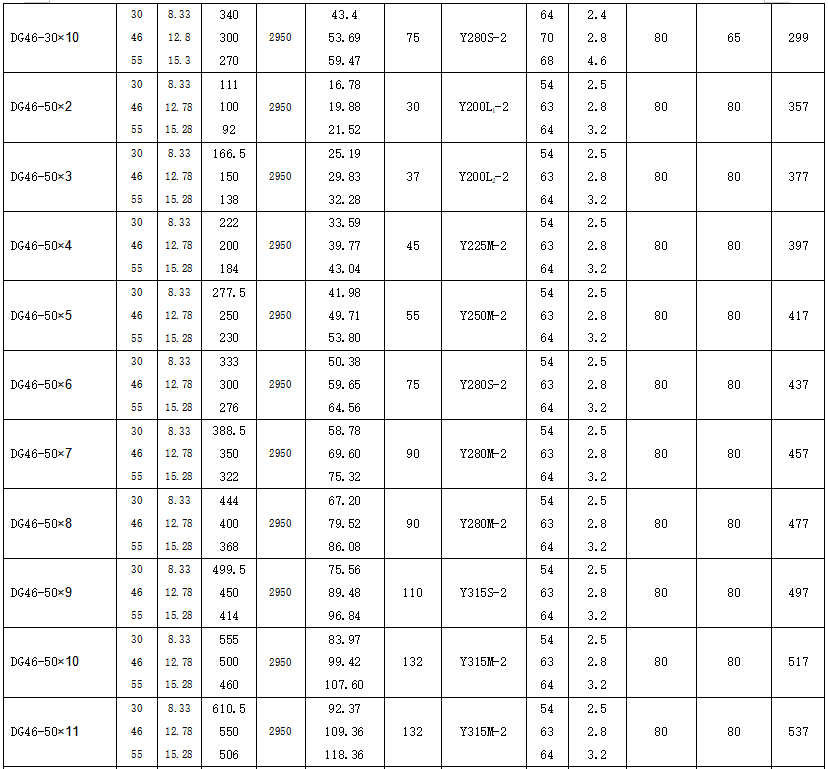

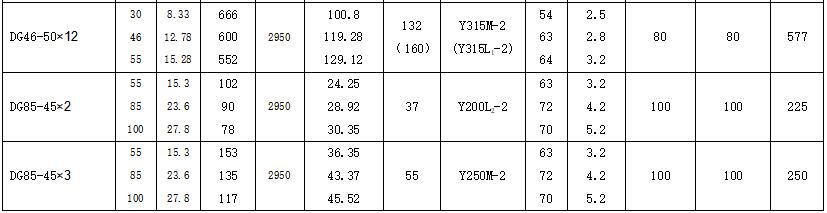

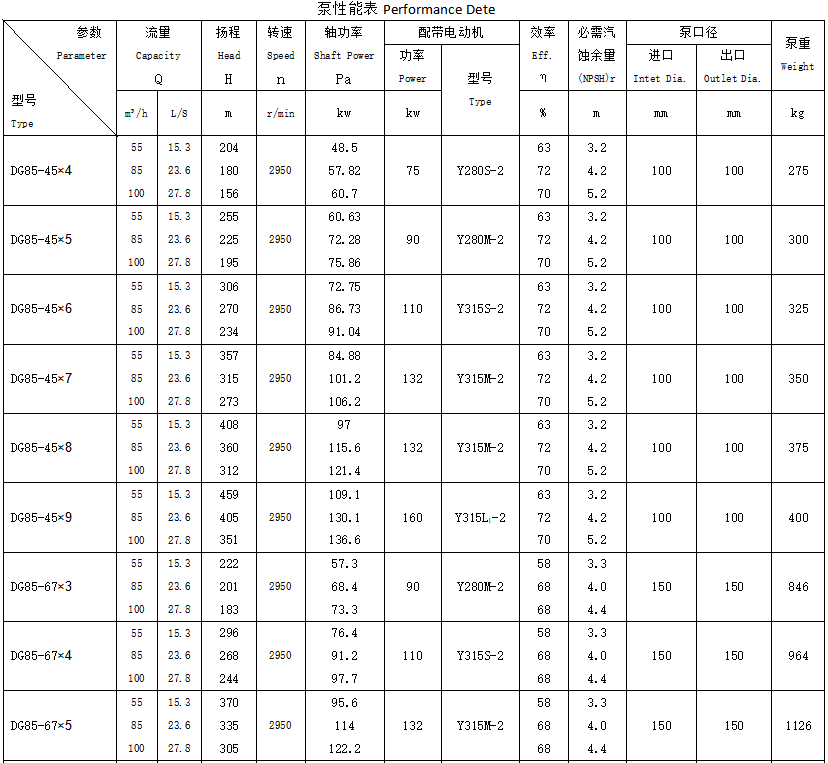

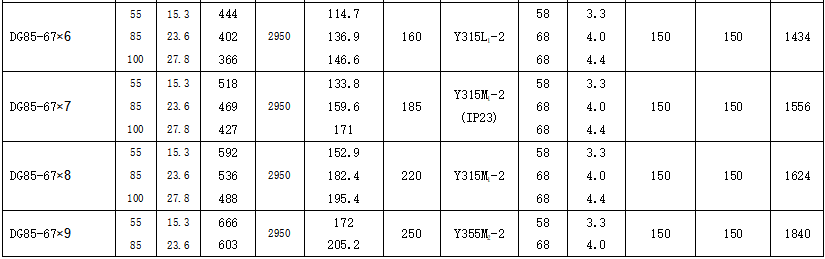

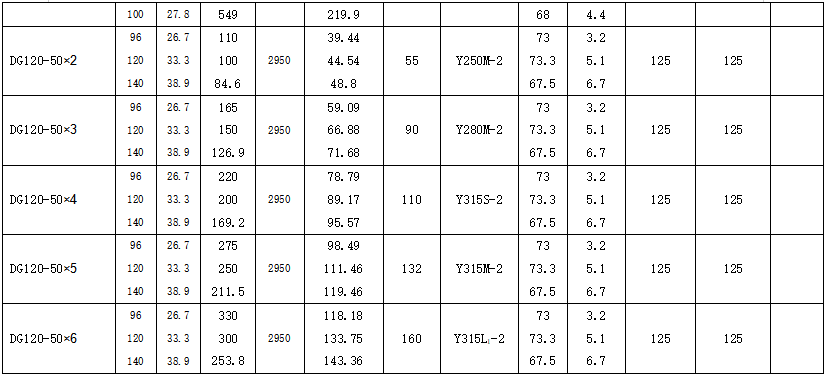

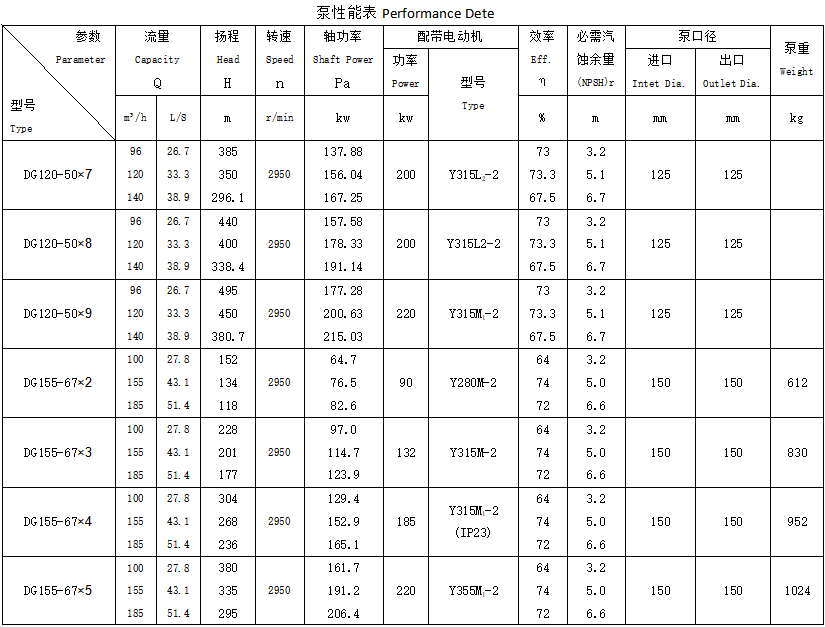

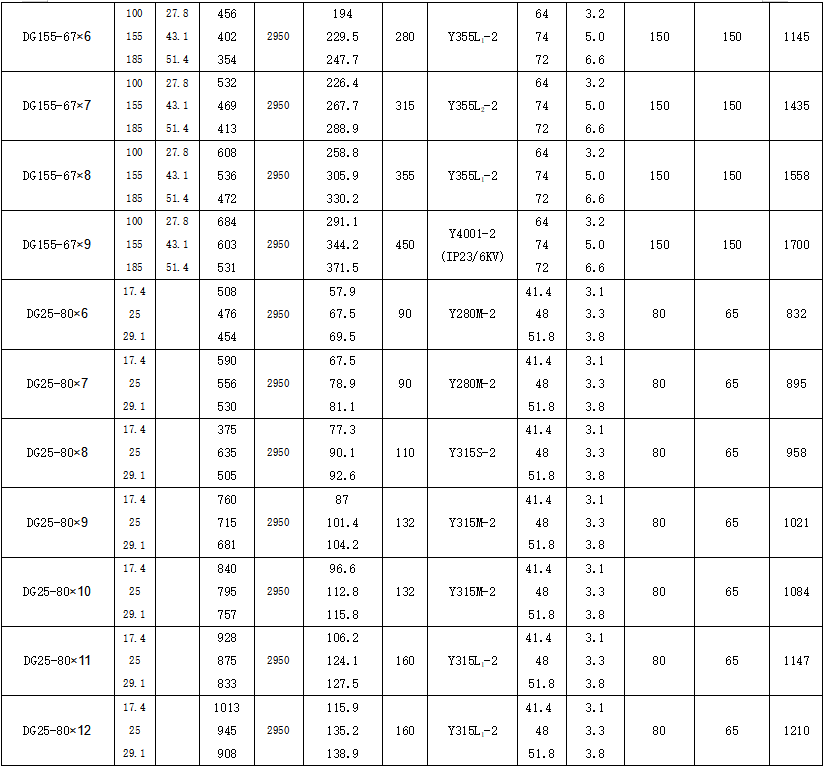

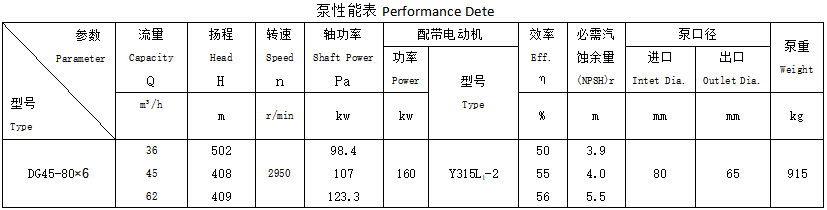

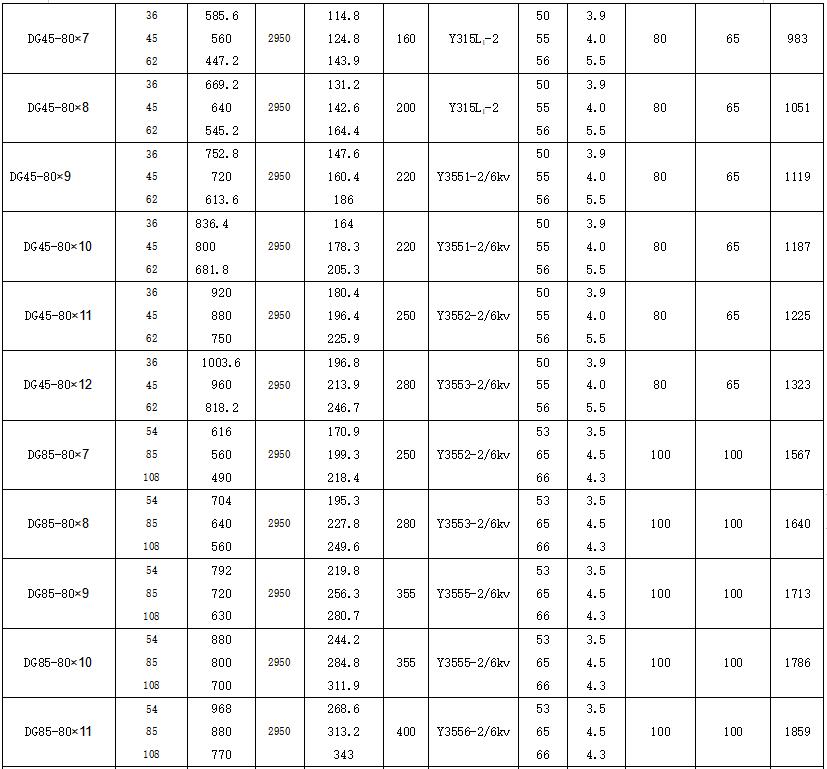

Performance range

Flow: Q=3.75~185m3/h

Lift: H=50~684m (medium and low pressure)

H=409~1056m (secondary high pressure)

The water inlet and outlet of DG type pump are vertically upward, and the pump shell parts such as the water inlet section, middle section, water outlet section and bearing body are connected into a whole by tightening bolts. Select the pump stage according to the pump lift.

The rotor part of this series of pumps is mainly composed of the shaft and the impeller, shaft sleeve, balance plate and other parts installed on the shaft. The number of impellers depends on the pump stage. The parts on the shaft are fastened with flat keys and shaft nuts to integrate with the shaft. The whole rotor is supported by rolling bearings or sliding bearings at both ends. The bearing is determined according to different models, and does not bear axial force. The axial force is balanced by the balance plate. During the operation of the pump, the rotor is allowed to swim axially in the pump casing, and the centripetal ball bearing cannot be used. The rolling bearing is lubricated with grease, and the sliding bearing is lubricated with thin oil, self lubricated with oil ring, and cooled with circulating water.

The sealing surfaces between the inlet section, middle section and outlet section of the pump are sealed with molybdenum disulfide grease. The sealing ring and guide vane sleeve are installed between the rotor part and the fixed part for sealing. When the wear of the sealing ring and guide vane sleeve has affected the working performance of the pump, they should be replaced.

There are two types of shaft seals: mechanical seal and packing seal. When the pump adopts the packing seal, the position of the packing ring should be correct, the tightness of the packing must be appropriate, and it is appropriate that the liquid can seep out drop by drop. Various sealing elements of the pump shall be installed in the sealing box, which shall be filled with water of certain pressure to play the role of water seal, water cooling or water lubrication. A replaceable shaft sleeve is installed at the shaft seal to protect the pump shaft.

The sub high pressure pump generally adopts sliding bearing and thin oil lubrication structure. DG85-67 and DG155-67 pumps can adopt sliding bearing, thin oil lubrication, or rolling bearing and dry oil lubrication structure. Other models adopt rolling bearing and dry oil lubrication structure. The main parts of medium and low pressure pumps are generally made of high-quality cast iron, and the main parts of sub high pressure pumps are made of cast steel or stainless steel. This series of pumps are directly driven by the prime mover through an elastic coupling. From the direction of the prime mover, the pump rotates clockwise.

DG type medium low pressure and sub high pressure series horizontal multi-stage boiler feed pump

Hundreds of customers to choose from