7 * 24-hour service hotline

+86 15836191545

1、 Product Overview

LG series water supply pump for high-rise buildings is a vertical single suction multi-stage segmented centrifugal pump, which is used to transport clean water at normal temperature and liquid with physical and chemical properties similar to clean water. LG series pumps are installed vertically. The motor shaft and pump shaft are connected by claw type couplings. They have the advantages of compact structure, low noise and small floor area. They are mainly used for water supply in high-rise buildings, as well as water supply and drainage in factories and mines, enterprises and circulating water for low-pressure boilers Scope of application: mainly used for water supply of high-rise buildings, as well as water supply and drainage of factories and mines, enterprises, and circulating water for low-pressure boilers.

2、 Model meaning

25LG3-10

25 - Diameter (mm)

LG multi-stage water supply pump for high-rise buildings

3-Flow (m3/n)

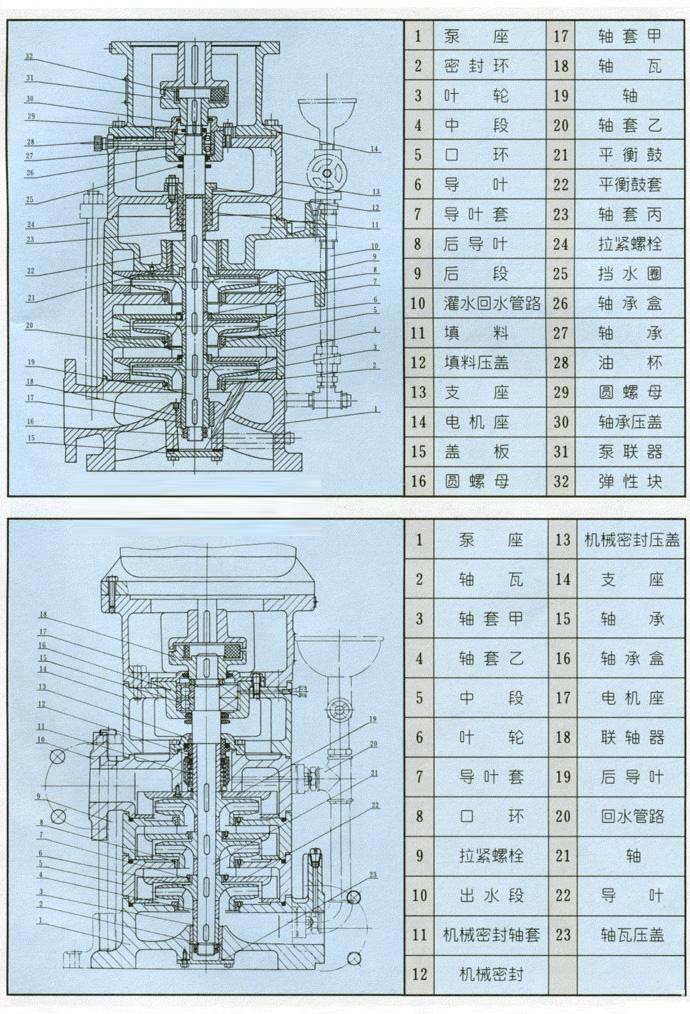

3、 Structural drawing

4、 Technical characteristics

1. The medium used shall be similar to water, with kinematic viscosity<150mm/s, and free of hard particles and corrosion;

2. Working pressure of larger system ≤ 2.5MPa

3. Service temperature of medium: - 15 ℃~+105 ℃;

4. Ambient temperature ≤ 40 ℃, relative humidity lower than 95%

5、 Structural characteristics

1. This series of pumps are of vertical, multi-stage and segmental structure. The inlet section, middle section and outlet section are fastened together with bolts. Each stage of the pump is equipped with an impeller and guide vane. Its axial force is hydraulically balanced, and the residual axial force is borne by one or a pair of ball bearings;

2. The pump is compact in structure, small in volume and beautiful in appearance. Its structure determines that the installation area is small. If it is equipped with a protective cover, it can be used outdoors;

3. The shaft seal adopts a specially designed mechanical seal. If it is necessary to remove the mechanical seal, it is not necessary to remove the motor. The sealing element can be taken out by removing the coupling of the intermediate clamping shell, which has the advantage of easy replacement and maintenance;

4. The drive of the pump is driven by a vertical motor through a jacket coupling. From the motor end, the pump rotates clockwise;

5. The suction inlet of the pump is at the bottom and the water outlet is at the top. The relative position of the pump can be one of 0 °, 90 °, 180 ° and 270 ° according to the user's requirements for assembly and delivery. Generally, the pump is delivered at 180 °;

6. No adjustment is required for assembly and disassembly;

7. The motor can be equipped with standard Y (Y2) series models.

6、 Installation and removal

Hundreds of customers to choose from