7 * 24-hour service hotline

+86 15836191545

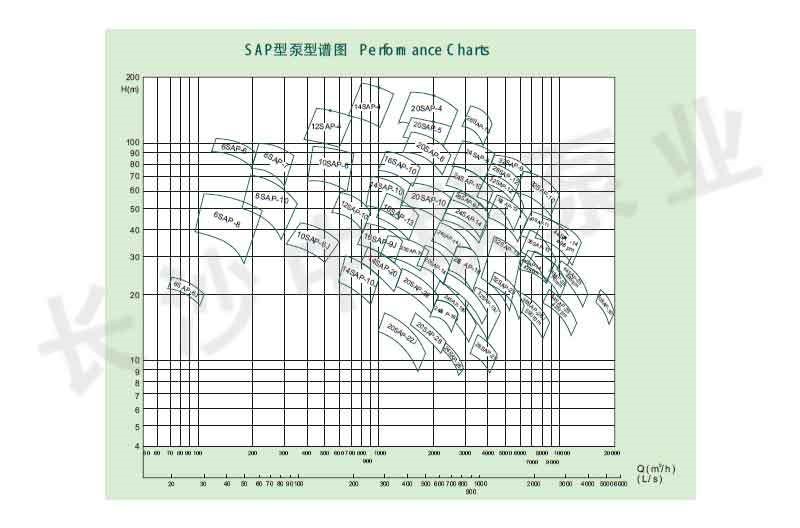

• Flow: 72-10800m ³/ h

• Lift: 15-280m

• Efficiency: 69% - 90%

• Pump weight: 110-25600kg

• Motor power: 11-2240kw

NPSH: 1.79-10.3m

SAP single-stage double suction split pump is a single-stage, double suction horizontal split centrifugal pump, which is suitable for factories, cities, mines, power stations, farmland, water conservancy projects and other fields. It is used to transport clean water without solid particles or other liquids with physical and chemical properties similar to water. The temperature of the medium to be transported is 0 ℃~80 ℃, and the allowable large inlet pressure is 0.6MPa. performance parameter

Parameter range and model description of SAP single-stage double suction horizontal split centrifugal pump:

Flow Q 72~20000 m3/h

Lift H 6.8~186m

Model: 300SAP-90

300 - suction diameter 250mm

90 - Lift

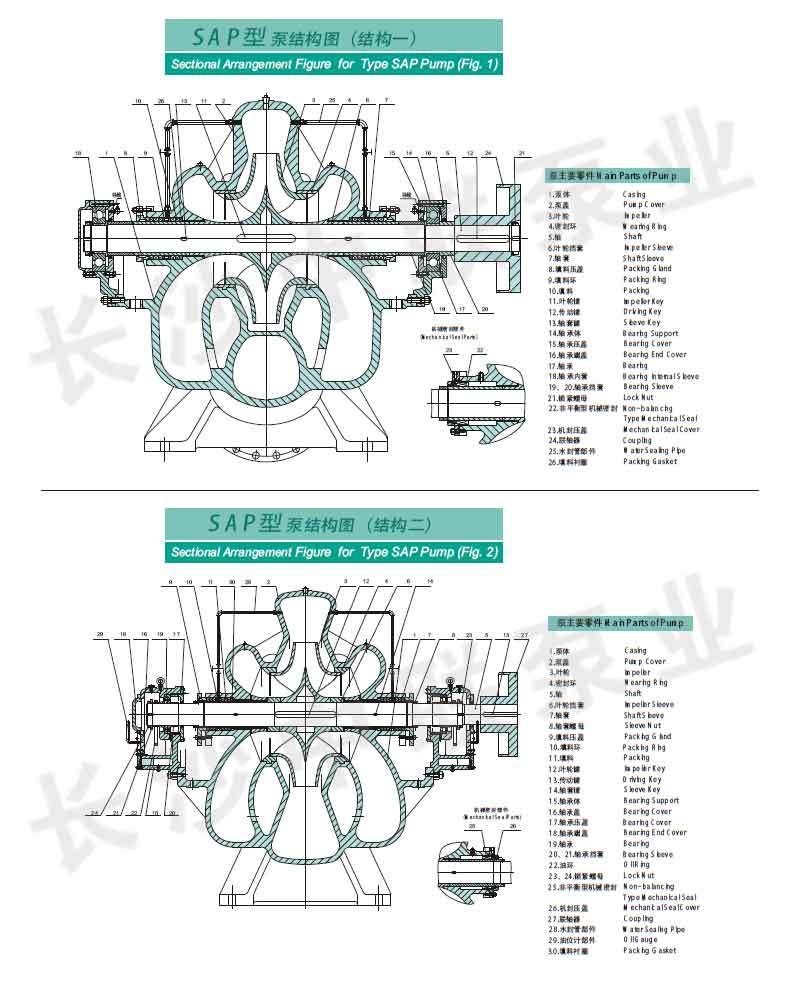

SAP single-stage double suction horizontal split centrifugal pump structure type:

The sap type horizontal double suction split pump is horizontally installed. The pump casing is horizontally separated from the shaft centerline. The upper part is the pump cover and the lower part is the pump body. The suction inlet and discharge outlet are both on the pump body below the pump axis, where the centerline is vertical to the axis. During maintenance, the pump cover can be removed and the rotor parts can be taken out without removing the water inlet and outlet pipelines. Except that 48SAP-30 pump is a sliding bearing, other types of pump bearings are rolling bearings, and the seal of bearing end cover is skeleton oil seal. The shaft seal adopts soft packing seal and mechanical seal.

Rotation direction: from the motor end to the pump, it rotates counterclockwise, that is, the suction inlet is on the left and the discharge outlet is on the right. The drive end can also be moved to the other end of the pump according to the user's requirements. At this time, the direction of rotation, suction and discharge is opposite to the above.

Material of main parts: the flow passage components of the pump are made of cast iron. If required by the user, the impeller can also be made of cast steel and brass, but it must be noted in the order contract.

Specific parameters of SAP single-stage double suction horizontal split centrifugal pump:

参数 | 流量 | 扬程 | 转速 | 轴功率 | 配带电动机 | 效率 | 必须汽 | 叶轮名义直径 | 进出口径 | 泵重 | ||

功率 | 型号 | |||||||||||

m3/s | L/s | m | r/min | kw | kw | % | m | mm | mm | kg | ||

6SAP-6 | 126 | 35.0 | 104 | 2980 | 49 | 75 | Y280S-2 | 73 | 3.0 | 270 | 150 | 160 |

6SAP-6A | 119 | 33.1 | 91 | 2980 | 42 | 75 | Y280S-2 | 70 | 3.0 | 256 | 150 | 160 |

6SAP-6J | 72 | 20.0 | 25 | 1480 | 6.71 | 11 | Y160M-4 | 73 | 2.6 | 270 | 150 | 160 |

6SAP-8 | 108 | 30.0 | 58 | 2980 | 24.4 | 37 | Y200L2-2 | 70 | 2.9 | 205 | 150 | 120 |

6SAP-8A | 108 | 30.0 | 46 | 2980 | 18 | 30 | Y200L1-2 | 76 | 2.9 | 185 | 150 | 120 |

6SAP-8B | 108 | 30.0 | 38 | 2980 | 15.5 | 22 | Y180M-2 | 72 | 2.9 | 170 | 150 | 120 |

8SAP-7 | 216 | 60.0 | 99 | 2980 | 78.6 | 132 | Y315M-2 | 74 | 4.0 | 272 | 200 | 255 |

8SAP-7A | 210 | 58.4 | 87 | 2980 | 68.2 | 110 | Y315S-2 | 73 | 4.0 | 255 | 200 | 255 |

8SAP-7B | 196 | 54.4 | 76 | 2980 | 57 | 75 | Y280S-2 | 72 | 4.0 | 240 | 200 | 255 |

8SAP-10 | 194 | 53.9 | 71 | 2980 | 52.1 | 75 | Y280S-2 | 72 | 2.8 | 235 | 200 | 180 |

8SAP-10A | 180 | 50.0 | 58 | 2980 | 40.6 | 55 | Y250M-2 | 70 | 2.7 | 217 | 200 | 180 |

8SAP-10B | 173 | 48.0 | 48 | 2980 | 32 | 45 | Y225M-2 | 70 | 2.6 | 200 | 200 | 180 |

10SAP-6 | 432 | 120.0 | 96 | 1480 | 162.6 | 250 | Y355M2-2 | 74 | 5.1 | 530 | 250 | 860 |

参数 | 流量 | 扬程 | 转速 | 轴功率 | 配带电动机 | 效率 | 必须汽 | 叶轮名义直径 | 进出口径 | 泵重 | ||

功率 | 型号 | |||||||||||

m3/s | L/s | m | r/min | kw | kw | % | m | mm | mm | kg | ||

10SAP-6A | 432 | 120.0 | 85.3 | 1480 | 129 | 220 | Y355M1-4 | 77.6 | 5.1 | 500 | 250 | 860 |

10SAP-6B | 432 | 120.0 | 76.4 | 1480 | 121 | 185 | Y355M-4 | 74 | 5.1 | 470 | 250 | 860 |

10SAP-6J | 400 | 111.1 | 42 | 980 | 58.7 | 90 | Y315M-6 | 78 | 3.6 | 530 | 250 | 860 |

10SAP-6JA | 300 | 83.3 | 36.9 | 980 | 39 | 75 | Y315S-6 | 76.4 | 3.3 | 500 | 250 | 860 |

10SAP-6JB | 300 | 83.3 | 33 | 980 | 34.7 | 55 | Y280M-6 | 77.5 | 3.3 | 470 | 250 | 860 |

10SAP-6F | 400 | 111.1 | 66.4 | 1480 | 95.2 | 160 | Y315L1-4 | 76 | 4.6 | 445 | 250 | 860 |

12SAP-4 | 450 | 125.0 | 144 | 1480 | 245 | 355 | Y400-4 | 72 | 2.3 | 634 | 300 | 1550 |

12SAP-10 | 610 | 169.4 | 59 | 1480 | 114 | 160 | Y315L1-4 | 86 | 4.1 | 418 | 300 | 1070 |

14SAP-4 | 800 | 222.2 | 186 | 1480 | 544 | 710 | Y450-4 | 74.5 | 3.4 | 724 | 350 | 2150 |

14SAP-10 | 900 | 250.0 | 70 | 1480 | 206.5 | 280 | Y355-4 | 83 | 5.1 | 466 | 350 | 1250 |

14SAP-10A | 900 | 250.0 | 60 | 1480 | 175 | 250 | Y355-4 | 84 | 5.1 | 440 | 350 | 1250 |

14SAP-10B | 900 | 250.0 | 51 | 1480 | 148 | 220 | Y355M-4 | 84 | 5.1 | 425 | 350 | 1250 |

14SAP-10J | 650 | 180.6 | 30 | 980 | 62.5 | 90 | Y315M-6 | 85 | 4.0 | 466 | 350 | 1250 |

参数 | 流量 | 扬程 | 转速 | 轴功率 | 配带电动机 | 效率 | 必须汽 | 叶轮名义直径 | 进出口径 | 泵重 | ||

功率 | 型号 | |||||||||||

m3/s | L/s | m | r/min | kw | kw | % | m | mm | mm | kg | ||

14SAP-10JA | 600 | 166.7 | 27 | 980 | 52.5 | 75 | Y315S-6 | 84 | 4.0 | 440 | 350 | 1250 |

14SAP-10JB | 600 | 166.7 | 23 | 980 | 44.2 | 75 | Y315S-6 | 85 | 4.0 | 425 | 350 | 1250 |

14SAP-10F | 450 | 125.0 | 15.6 | 742 | 22.8 | 37 | Y280S-8 | 84. | 5.8 | 440 | 350 | 1250 |

14SAP-20 | 870 | 241.7 | 33 | 1480 | 101.5 | 132 | Y315M-4 | 77 | 5.8 | 340 | 350 | 1330 |

16SAP-9J | 900 | 250.0 | 42 | 980 | 129 | 185 | Y355M-6 | 80 | 4.6 | 535 | 400 | 1980 |

16SAP-9JA | 900 | 250.0 | 37 | 980 | 111.9 | 160 | Y315M-6 | 81 | 4.6 | 510 | 400 | 1980 |

16SAP-9JB | 800 | 222.2 | 33 | 980 | 89.8 | 132 | Y315M-6 | 80 | 4..6 | 480 | 400 | 1980 |

16SAP-10 | 1120 | 311.1 | 91 | 1480 | 333 | 500 | Y400-4 | 83.3 | 5.9 | 530 | 400 | 1980 |

16SAP-13 | 1100 | 305.6 | 58.5 | 1480 | 210 | 280 | Y355-4 | 83.6 | 8.2 | 445 | 400 | 1350 |

20SAP-4 | 1500 | 416.7 | 171 | 980 | 949 | 1600 | Y630-6 | 73.7 | 3.1 | 1050 | 500 | 6050 |

20SAP-5 | 1667 | 463.1 | 130.4 | 980 | 812.8 | 1120 | Y500-6 | 72.8 | 4.0 | 955 | 500 | 3750 |

20SAP-6 | 1500 | 416.7 | 112 | 980 | 572 | 800 | Y500-6 | 80 | 3.4 | 830 | 500 | 5700 |

20SAP-10 | 1500 | 416.7 | 65.5 | 980 | 339 | 500 | Y450-6 | 79 | 6.6 | 690 | 500 | 4168 |

参数 | 流量 | 扬程 | 转速 | 轴功率 | 配带电动机 | 效率 | 必须汽 | 叶轮名义直径 | 进出口径 | 泵重 | ||

功率 | 型号 | |||||||||||

m3/s | L/s | m | r/min | kw | kw | % | m | mm | mm | kg | ||

20SAP-14 | 1920 | 533.3 | 33 | 980 | 200.6 | 280 | Y400-6 | 86 | 3.8 | 505 | 550 | 3740 |

20SAP-20 | 1620 | 450.0 | 38 | 1480 | 212 | 250 | Y400-6 | 79 | 6.4 | 393 | 500 | 1660 |

20SAP-22 | 1368 | 380.0 | 26.2 | 980 | 122 | 160 | Y355M-6 | 80 | 4.4 | 466 | 500 | 1660 |

20SAP-22A | 1260 | 350.0 | 21 | 980 | 90 | 110 | Y315S-6 | 80 | 4.3 | 425 | 500 | 1660 |

20SAP-22J | 1080 | 300.0 | 16.3 | 742 | 61.4 | 75 | Y315M-8 | 78 | 2.8 | 466 | 500 | 1660 |

20SAP-22JA | 1080 | 300.0 | 10.3 | 742 | 37 | 55 | Y315S-8 | 82 | 2.8 | 425 | 500 | 1660 |

20SAP-28 | 1585 | 440.0 | 16.4 | 980 | 86.2 | 110 | Y315S-6 | 82 | 4.7 | 385 | 500 | 1660 |

24SAP-6 | 2880 | 800.0 | 102 | 980 | 931 | 1250 | Y560-6 | 86 | 6.2 | 820 | 600 | 5490 |

24SAP-10 | 2592 | 720.0 | 78 | 980 | 649 | 900 | Y500-6 | 85.5 | 5.6 | 716 | 600 | 4100 |

24SAP-10B | 2338 | 649.4 | 63.5 | 980 | 472.8 | 630 | Y450-6 | 85.5 | 4.6 | 655 | 600 | 4100 |

24SAP-10J | 2160 | 600.0 | 43 | 742 | 290 | 400 | Y450-8 | 87 | 5.6 | 716 | 600 | 4100 |

24SAP-14 | 2520 | 700.0 | 54.5 | 980 | 460 | 630 | Y450-6 | 81.5 | 5.3 | 624 | 600 | 4200 |

24SAP-18 | 2700 | 750.0 | 33.5 | 980 | 292 | 400 | Y400-6 | 84.5 | 6.1 | 550 | 600 | 3500 |

参数 | 流量 | 扬程 | 转速 | 轴功率 | 配带电动机 | 效率 | 必须汽 | 叶轮名义直径 | 进出口径 | 泵重 | ||

功率 | 型号 | |||||||||||

m3/s | L/s | m | r/min | kw | kw | % | m | mm | mm | kg | ||

24SAP-18A | 2520 | 700.0 | 25.5 | 980 | 206 | 250 | Y355-6 | 85 | 6.0 | 490 | 600 | 3500 |

24SAP-18J | 2070 | 575.0 | 18.8 | 742 | 126 | 160 | Y355M-8 | 84 | 3.7 | 535 | 600 | 3500 |

24SAP-18JA | 1908 | 530.0 | 14.7 | 742 | 85.6 | 110 | Y315L2-8 | 84.5 | 3.2 | 490 | 600 | 3500 |

*24SAP-18D | 2160 | 600.0 | 23.2 | 742 | 166.4 | 200 | Y355M-8 | 82 | 4.7 | 539 | 600 | 3500 |

*24SAP-18F | 1800 | 500.0 | 33.2 | 980 | 241.6 | 315 | Y400-6 | 67.4 | 4.6 | 510 | 600 | 3500 |

24SAP-28 | 2412 | 670.0 | 25.1 | 980 | 205 | 250 | Y355-6 | 80 | 5.9 | 455 | 600 | 3200 |

26SAP-10 | 3217 | 894 | 145 | 1480 | 1537 | 2000 | Y560-4 | 82.5 | 6.0 | 695 | 650 | 5500 |

28SAP-9J | 2111 | 586 | 60.1 | 742 | 432 | 630 | Y500-8 | 80 | 4.4 | 840 | 700 | 6800 |

28SAP-12 | 4300 | 1194 | 80.4 | 980 | 1095 | 1400 | Y560-6 | 86 | 5.9 | 780 | 700 | 6450 |

28SAP-25 | 4000 | 1111 | 22.5 | 742 | 298 | 400 | Y450-8 | 82 | 7.3 | 585 | 700 | 5000 |

32SAP-9 | 4680 | 1300 | 87.4 | 742 | 1303 | 1800 | Y710-8 | 85.8 | 6.6 | 1025 | 800 | 8250 |

32SAP-10 | 6300 | 1750 | 73.5 | 742 | 1510 | 2240 | Y710-8 | 83.5 | 5.9 | 990 | 800 | 8680 |

32SAP-10A | 5940 | 1650 | 67.8 | 742 | 1321 | 1800 | Y710-8 | 83 | 5.8 | 950 | 800 | 8680 |

参数 | 流量 | 扬程 | 转速 | 轴功率 | 配带电动机 | 效率 | 必须汽 | 叶轮名义直径 | 进出口径 | 泵重 | ||

功率 | 型号 | |||||||||||

m3/s | L/s | m | r/min | kw | kw | % | m | mm | mm | kg | ||

32SAP-10B | 5760 | 1600 | 59 | 742 | 1129 | 1600 | Y630-8 | 82 | 5.7 | 885 | 800 | 8680 |

32SAP-10J | 4860 | 1350 | 48.3 | 590 | 780 | 1120 | Y630-10 | 82 | 3.7 | 990 | 800 | 8680 |

32SAP-10JA | 4680 | 1300 | 44 | 590 | 684 | 1000 | Y630-10 | 82 | 3.6 | 950 | 800 | 8680 |

32SAP-10JB | 3960 | 1100 | 31.5 | 495 | 414 | 560 | Y560-12 | 82 | 2.8 | 952 | 800 | 8680 |

32SAP-12 | 3960 | 1100 | 72.5 | 980 | 930.8 | 1120 | Y560-6 | 84 | 5.0 | 740 | 800 | 5750 |

32SAP-12J | 2880 | 800.0 | 41.3 | 742 | 383.3 | 500 | Y5001-8 | 84.5 | 2.7 | 740 | 800 | 5750 |

32SAP-13 | 4500 | 1250 | 57 | 742 | 794 | 1000 | Y560-8 | 88 | 3.5 | 870 | 800 | 6650 |

32SAP-19 | 4390 | 1219.4 | 33.3 | 742 | 470 | 560 | Y500-8 | 84.6 | 6.3 | 708 | 800 | 5740 |

32SAP-19A | 4170 | 1158.3 | 29.3 | 742 | 391.5 | 500 | Y500-8 | 85 | 6.1 | 670 | 800 | 5740 |

32SAP-19B | 3654 | 1015.0 | 23.7 | 742 | 276 | 355 | Y450-8 | 85.5 | 6.0 | 616 | 800 | 5740 |

32SAP-19J | 3456 | 960.0 | 21.6 | 590 | 231.5 | 280 | Y450-10 | 87.8 | 3.5 | 708 | 800 | 5740 |

32SAP-19JA | 3240 | 900.0 | 19.1 | 590 | 192.6 | 250 | Y450-10 | 87.5 | 4.0 | 668 | 800 | 5740 |

32SAP-19JB | 2880 | 800.0 | 15.8 | 590 | 146.6 | 200 | Y450-10 | 84.5 | 3.9 | 610 | 800 | 5740 |

参数 | 流量 | 扬程 | 转速 | 轴功率 | 配带电动机 | 效率 | 必须汽 | 叶轮名义直径 | 进出口径 | 泵重 | ||

功率 | 型号 | |||||||||||

m3/s | L/s | m | r/min | kw | kw | % | m | mm | mm | kg | ||

32SAP-19E | 4320 | 1200.0 | 36.8 | 742 | 512 | 630 | Y500-8 | 84.5 | 5.9 | 730 | 800 | 5740 |

32SAP-19F | 3600 | 1000.0 | 27.3 | 742 | 320 | 400 | Y450-8 | 83.7 | 5.8 | 630 | 800 | 5740 |

32SAP-25 | 4320 | 1200.0 | 25.2 | 742 | 352 | 400 | Y450-8 | 84.2 | 5.1 | 620 | 800 | 6000 |

36SAP-13 | 6800 | 1888.9 | 39.5 | 495 | 861 | 1120 | Y710-12 | 85 | 4.5 | 1068 | 900 | 17700 |

36SAP-28 | 7200 | 2000 | 32 | 742 | 760.5 | 900 | Y560-8 | 82.5 | 11.0 | 715 | 900 | 12800 |

40SAP-11 | 7000 | 1944.4 | 48 | 495 | 1099 | 1600 | Y800-12 | 83.6 | 3.7 | 1178 | 1000 | 13200 |

44SAP-14 | 8100 | 3250 | 45.2 | 495 | 1187 | 1600 | Y800-12 | 84 | 5.0 | 1120 | 1100 | 17800 |

44SAP-25 | 8100 | 2250.0 | 29.6 | 495 | 793.9 | 1120 | Y710-12 | 82.3 | 6.1 | 1000 | 1100 | 16500 |

48SAP-30 | 17000 | 4722.2 | 21 | 1250 | 1080 | 1250 | Y710-12 | 90 | 8.5 | 1010 | 1200 | 24800 |

Assembly and disassembly of pump

1. Assembly of rotor parts: for the packing pump, install the impeller, shaft sleeve, shaft sleeve nut, packing ring and packing in turn

The packing gland, water retaining ring and bearing components shall be sleeved with double suction seal ring, and then the coupling shall be installed. For the mechanical seal pump, install the impeller, shaft sleeve, mechanical seal retaining sleeve, mechanical seal moving ring, static ring, mechanical seal gland, bearing components in turn, and cover the double suction seal ring, and then install the coupling.

2. Respectively check the radial runout of the outer circle of the seal part and the outer circle of the shaft sleeve of the impeller on the rotor part, which shall not exceed the value specified in the following table (mm)

名义直径 | <50 | 50-120 | 125-250 | 250-500 | 500-800 | 800-1250 |

跳动量 | 0.03 | 0.04 | 0.05 | 0.06 | 0.08 | 0.1 |

3. Install the rotor parts and studs on the pump body, install the bearing body gland, and adjust the axial direction of the impeller with the shaft sleeve nut

Position to the middle of the pump body flow passage and fix it. The bearing body gland shall be fastened with fixing screws.

4. Place the split face paper pad, cover the pump cover, tighten the taper pin of the screw tail, and then tighten the pump cover nut. For packing pumps,

Do not press the packing too tightly. If the packing is too tight, the shaft sleeve will heat up. At the same time, the energy consumption will increase. Do not press too loosely. If the packing is too loose, the liquid leakage will increase and the pump efficiency will decrease.

After the assembly is completed, rotate the pump shaft by hand without rubbing, and rotate it gently and evenly. The disassembly can be carried out in the reverse order of the above assembly.

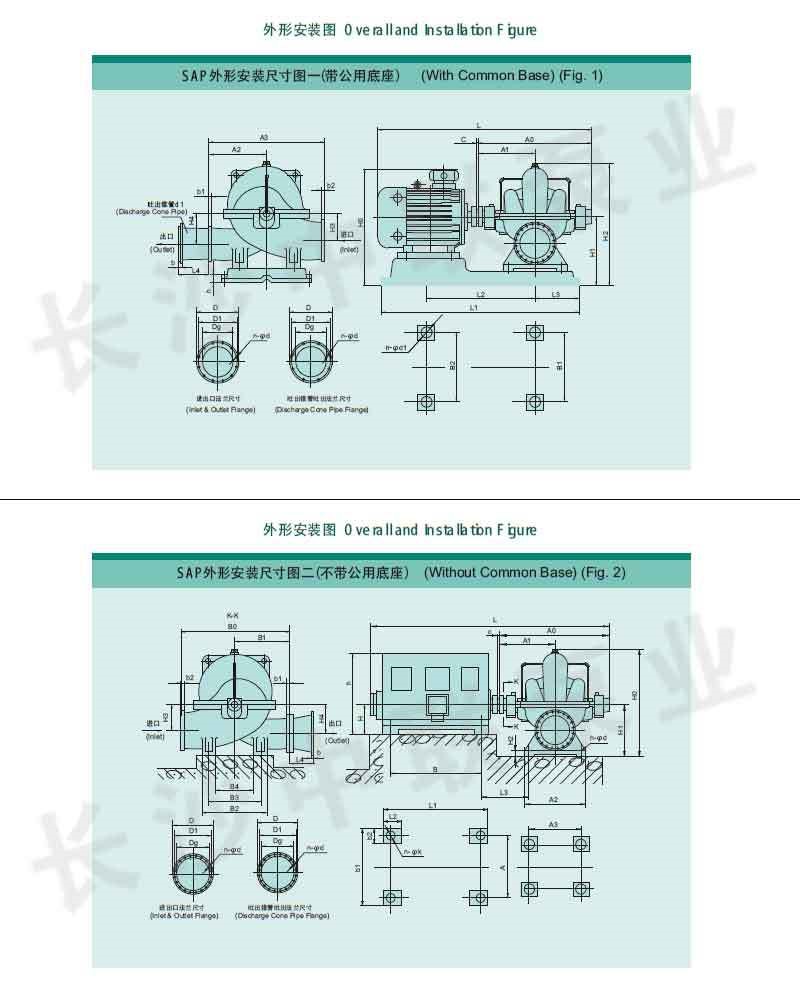

Precautions for pump installation

1. Check whether the water pump and motor are damaged.

2. The installation height of the water pump, together with the hydraulic loss of the suction pipeline and its speed energy, shall not be greater than the allowable suction vacuum height specified in the sample. The foundation size shall conform to the installation size of the pump unit.

3. Installation sequence

Put the water pump and motor on the foundation bolt, put on the nut, and place them on the concrete foundation with the reserved foundation bolt hole.

Use the method of adjusting wedge cushion block to correct the level, and calibrate the coaxiality of pump and motor shaft. Then fill all anchor bolt holes with concrete.

(2) After the concrete is dry and solidified, the coaxiality of the pump and motor shaft shall be corrected on the outer circle of the two couplings, and the error shall not be greater than 0.1mm. The tolerance of the non-uniformity of the end machine clearance along the circumference is 0.3mm. After fastening the anchor nut, check the correction accuracy, and then fill the bottom of the motor and pump foot with concrete, but space must be left around the wedge block

(3) After checking that the rotation direction of the motor is consistent with that of the water pump, install the coupling pin.

4. The water inlet and outlet pipes shall be supported by another support, not by the pump body.

5. The joint surface between the water pump and the pipeline shall ensure good air tightness, especially the inlet and outlet water pipes must be strictly air tight, and there shall be no possibility of trapping air on the device.

6. If the water pump is installed above the water inlet level, in order to fill and start, the bottom valve should be installed, or the method of vacuumizing water can be used.

The above are the installation methods and requirements for the pump unit without a common base

Refer to the above method.

7. Generally, gate valve and check valve shall be installed between the water pump and the outlet pipe (not required if the lift is less than 20m), and the check valve shall be installed behind the gate valve.

Start, stop and operation of pump

1 Start and stop:

Before starting: rotate the rotor of the pump, and it should slide gently and evenly.

(2) Close the water outlet gate valve and inject water into the pump (if there is no bottom valve, use a vacuum pump to draw water). Ensure that the pump is full of water and free of air.

(3) If a vacuum gauge or pressure gauge is installed on the pump, close the cock connected to the pump before starting the motor, open it after the speed is normal, and then gradually open the outlet gate valve. If the flow is too large, you can properly close the valve to adjust, otherwise, if the flow is too small, open the gate valve.

(4) Tighten the compression nuts on the packing gland evenly to make the liquid leak out in drops, and pay attention to the temperature rise at the packing chamber.

(5) When the pump is stopped, first close the cocks of the vacuum gauge and pressure gauge and the gate valve on the outlet pipe, and then turn off the power supply of the motor. If the ambient temperature is low, open the square screw plug at the lower part of the pump to remove the residual water to avoid frost cracking.

(6) When it is not used for a long time, the water pump shall be disassembled, the water on the parts shall be wiped dry, and the processing surface shall be coated with antirust oil for safekeeping.

2 Operation:

(1) The high temperature of water pump bearing shall not exceed 750C.

(2) The quantity of calcium base grease used to lubricate the bearing should be 1/3/1/2 of the bearing body space and should be replaced regularly.

(3) When the packing is worn, the packing gland can be properly pressed. If it is worn too much, it should be replaced. Generally, the mechanical seal will not be worn and has a service life of up to one year.

(4) Regularly check the elastic coupling components and pay attention to the temperature rise of motor bearing.

(5) In case of noise or other abnormal sounds during operation, stop the machine immediately, check the causes and eliminate them.

(6) It is not allowed to increase the speed of the water pump arbitrarily, but it can be used at a lower speed.

Hundreds of customers to choose from