7 * 24-hour service hotline

+86 15836191545

◎ overview

1. The n-type condensate pump is mainly used for conveying condensate water in the fire missile plant, and can also be used in other places where the medium is similar to condensate water. The pump has good suction performance.

100n130 and 150n110 pumps can transport liquids below 120 ℃, while other pumps cannot transport liquids above 80 ℃.

100n130 and 150n110 pumps can be used as running water pumps after cooling water is introduced into the stuffing box and packing gland respectively.

2. 100nb45 and 100nb60 pumps are single-stage single suction cantilever condensate pumps, which are used for conveying condensate water to steam turbine generator units. It is characterized by good cavitation performance consumption and low injection head. It is suitable for supporting 500 and 1000 Watt steam turbine generator sets.

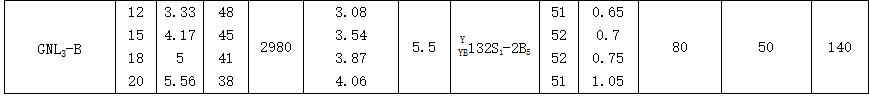

3. GN type pump is a two-stage single suction centrifugal condensate pump, which is used for pumping condensate from 750-3000 kW steam turbine generator units. This type of pump is characterized by high suction lift and small flow. If other industrial and mining enterprises have such requirements for pumps, they can also be used.

At present, the GN pumps produced by our factory are: gn3 / 12, gnl3-a, gnl3-b.

Model description

1. Example: 3n6 × 2 and 4n6a are

3 or 4 - suction pipe diameter is 25, except

N-horizontal cantilever condensate pump

6 - the designed lift of a single machine is divided by 10 and taken as an integer, that is, the lift of a single machine is about 60m

2-stage 9, indicating that the pump is composed of two stages

A - impeller has been cut (outer diameter reduced)

2. Example: 100nb60

100 - diameter of pump inlet is 100mm

NB - cantilever condensate pump

60 - pump lift is 60m

3. Example: gn3 / 12 gml3-a gnl3-b

GN - high suction condensate pump

L-vertical type (horizontal type without letter L)

3 - the suction diameter is 3mm, which is rounded by 25. The suction diameter of this type of pump is about 80mm

12. A, B, etc. - used to represent different performance parameters

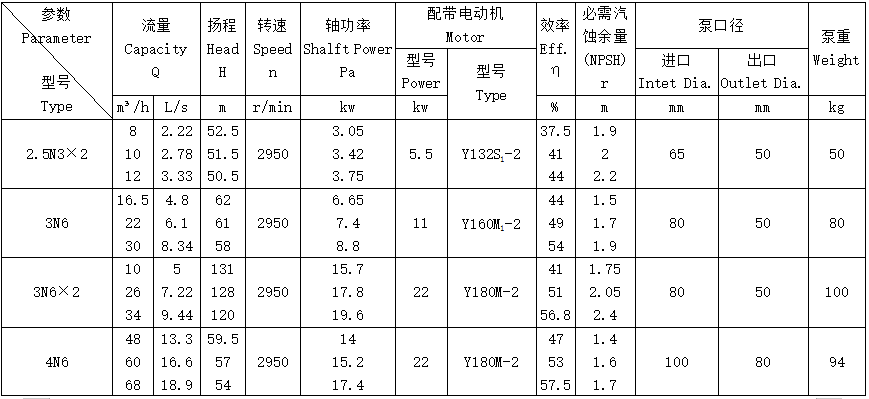

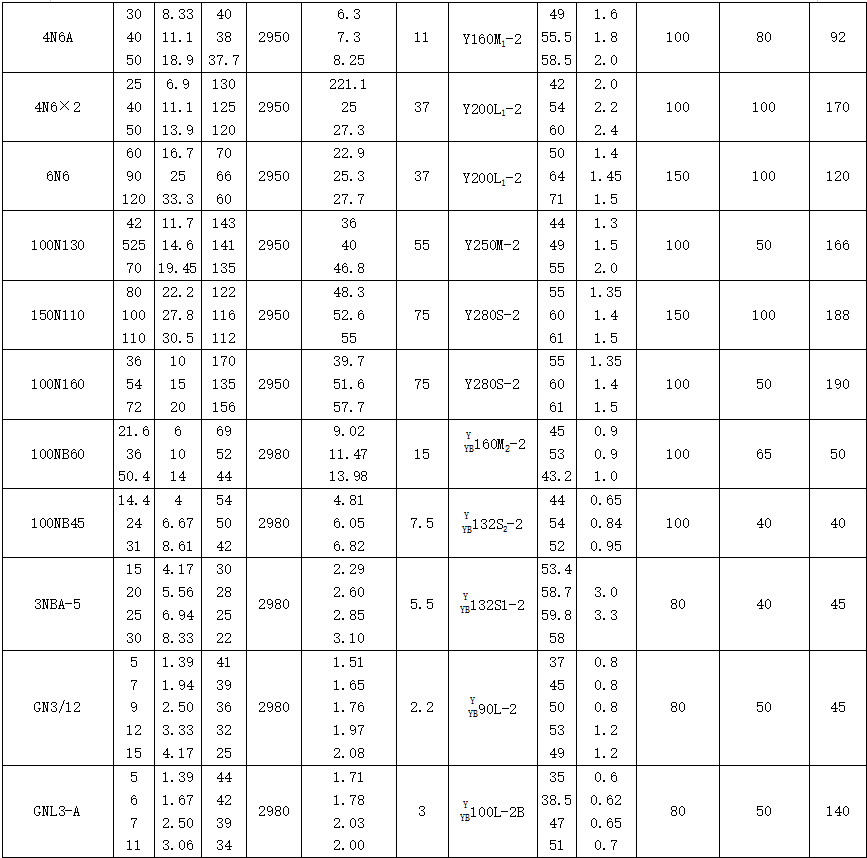

Performance range

Flow: q = 8 ~ 120m ³/ h

Lift: H = 38 ~ 143m

1、 N-type condensate pump

1. Variety

There are 10 types of n-type condensate pumps, including horizontal cantilever single-stage, two-stage and single-stage with inducer. Single stage includes 3n6, 4n6, 100n130 and 100n160; There are 2.5n3 in two levels × 2、3N6 × 2 and 4n3 × 2; There are 6n6 and 150n110 single-stage induction wheels.

2. Supporting part

The structure of the three varieties is the same. The main parts are the bracket, the front and rear bearing glands and the shaft. The front and rear radial ball bearings positioned on the bracket also generate unbalanced axial force. With rare lubricating oil, the oil quantity can be seen from the oil mark. The front and rear bearing glands are equipped with felt sealing rings as shaft seals to prevent oil leakage. Our country is sealed to prevent oil leakage. The hole at the pipe plug is used for filling oil. Drain the oil from the screw hole when cleaning and changing the oil.

3. Seal and drive

The pump is sealed with soft packing, and the shaft seal is equipped with a replaceable shaft shell sleeve.

The pump is driven by the motor through the elastic coupling. Viewed from the transmission direction, the pump rotates counterclockwise.

4. Work part

Single stage: the main parts are the impeller made of silicon brass 80-3, which is fixed on the shaft made of 45 high-quality carbon steel. The impeller is installed in the pump working chamber formed by the pump body and pump cover made of wear-resistant cast iron HT20-40. The power machine drives the shaft and impeller supported in the bearing through the coupling, and the pump works. The shaft sleeve made of wear-resistant cast iron HT20-40 is connected with the bushing (6n6 and 4n6) × 2) There is a water lubricated bearing between them. The stuffing box behind the pump body is equipped with a packing ring, and the packing oil immersed graphite asbestos rope. The packing gland is opened, and the packing is pressed with the help of an elongated stud bolt, and the tightness can be adjusted. The sealing water with high atmospheric pressure is introduced from the outside. By aligning the connecting pipe with the packing ring, a sealing cavity is formed in the entire stuffing box to isolate air from entering the pump, and at the same time, the water in the pump is prevented from flowing out, Only a small amount of lubricating water drips out. The impeller is provided with a balancing hole. In order to make the inlet of the high-pressure area communicate with the low-pressure area so as to eliminate the axial thrust, in order to prevent wear of the body and pump cover, facilitate repair and achieve good sealing, seal rings are installed on the pump body and pump cover, and wire holes are provided on the upper part of the pump body for bleeding. When the pump is stopped for maintenance, the water in the pump is discharged from the wire holes. In order to facilitate the grasp and removal of the pump body and pump cover, cap screws are provided, and pressure taps are provided at the inlet and outlet.

Two stages: the rest are the same as the single stage. Only the pump body, pump cover and intermediate guide vane constitute two working chambers. The first stage impeller made of silicon brass 80-3 and the blade office made of cast iron hta20-40cuo are installed in the two chambers.

Single stage with inducer: the rest are the same as the single stage, except that the material of the transmission line of the blade is aluminum iron bronze 9-4. An inducer made of aluminum iron bronze 90-4 is added in front of the impeller to improve cavitation performance.

2、 NB, NBA type condensate pump

The structure of this type of pump is basically the same as that of the general cantilever pump. The main parts are: water inlet, pump body, impeller, shaft, bracket, bearing, etc. It should be pointed out that there is no impeller nut in both pumps, so the water inlet should be removed first when disassembling and replacing the impeller, and the coupling nut should be unscrewed, and the impeller and shaft should be pulled out from the water inlet end. Do not forget to install the O-type rubber seal ring during assembly.

The lubricating water at the packing of 100nb45 pump is introduced from the drilling hole of the pump body. In addition to the lubricating water pipe, 100nb60 pump also has a balance water pipe to balance the axial force. When viewed from the water inlet to the coupling end, the impeller rotates clockwise.

3、 GN, GNL type condensate pump

1. Horizontal

It is basically the same as the general segmental multistage pump. The fixed part is mainly composed of water inlet section, middle section, water outlet section, bearing body, guide vane, seal ring and other parts. The rotating part is mainly composed of impeller sleeve, impeller, shaft and other parts. The axial force of the rotating part is borne by the ball bearing, and the radial force is borne by the ball bearing and the sleeve bearing on the guide vane.

Cooling chambers are provided around the stuffing box and on the bearing body, and cooling water can be introduced if necessary. The water inlet direction is axial, and the water outlet direction is vertical and upward.

2. Vertical, the fixed part is mainly composed of pump body, pump cover, support, seal ring, sleeve bearing, bearing body and other parts. The pump body and the pump cover are separated along the axis. The rotating part is mainly composed of impeller, shaft, shaft sleeve and other parts. The rotating part and axial force are borne by the bearing, and the radial force is borne by the ball bearing and the sleeve bearing located between the two wheels.

The bearing body is equipped with a cooling chamber, and cooling water can be introduced if necessary.

The suction and discharge ports of the pump are cast on the pump body. Their center lines are located on two horizontal straight lines respectively. The lower part of the pump body has a semicircular pump foot, and the upper part has a semicircular support. The support is installed on it, and the motor is installed on this support.

The horizontal pump is relatively light, but the internal parts of the pump can only be overhauled after the pipeline is disassembled. The vertical pump occupies a small area and is convenient for maintenance. It is only necessary to open the pump cover to overhaul all parts in the pump.

Hundreds of customers to choose from