7 * 24-hour service hotline

+86 15836191545

summary

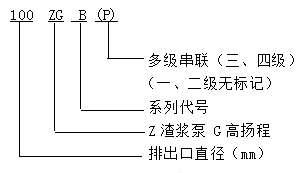

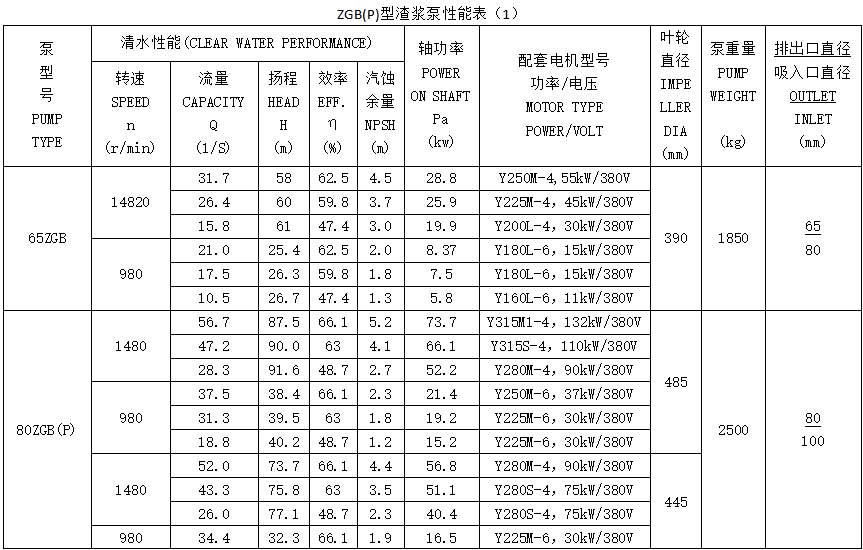

In order to meet the development needs of electric power, metallurgy, coal and other industries, our factory has developed a new generation of ZGB (P) series slurry pumps with large flow, high lift and multistage series connection in China, based on decades of experience in the design and manufacture of slurry pumps and widely absorbing advanced technologies and research achievements at home and abroad.

The main technical features of this series of products are as follows:

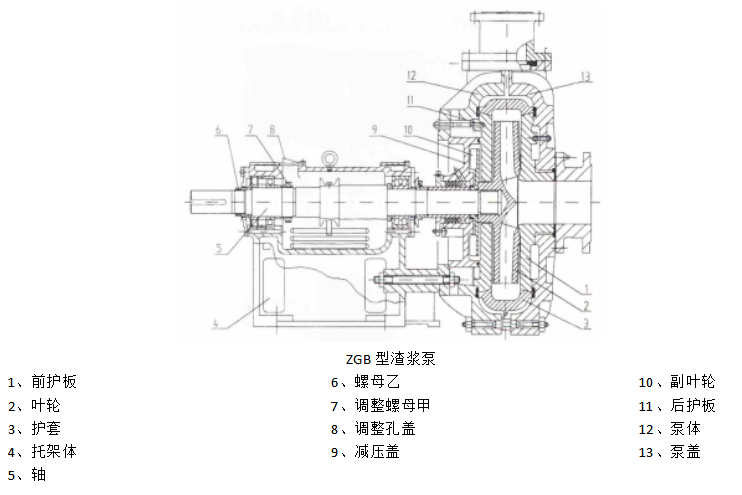

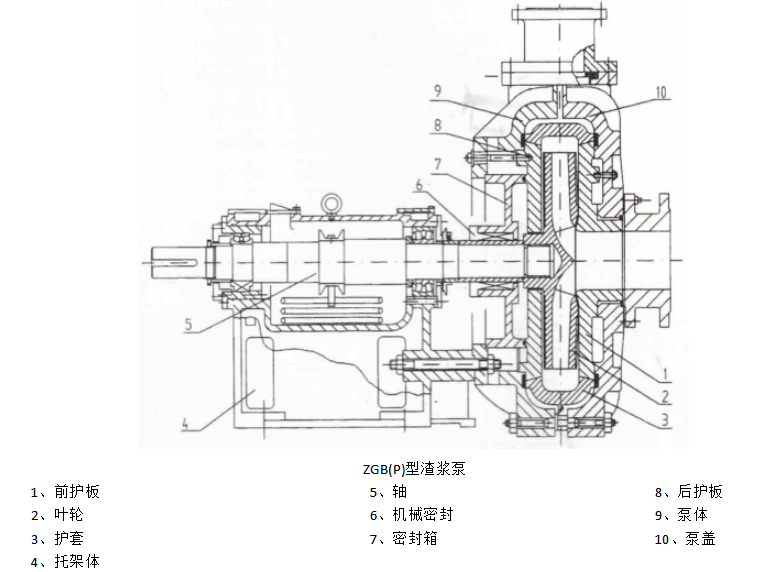

With modern CAD design method, the hydraulic performance is excellent, the efficiency is high and the wear rate is low; Wide flow passage, good anti clogging performance and superior cavitation performance; The auxiliary impeller and packing combined seal and mechanical seal are adopted to ensure no leakage of slag slurry; Reliability design ensures that the mean time between failures (MTBF) of the whole machine is greatly improved; Metric bearings are lubricated with thin oil, and lubrication and cooling systems are reasonably set to ensure that the bearings operate at low temperatures; The flow passage parts are made of special materials with good wear and corrosion resistance; After special treatment, it is used for seawater ash removal and seawater and salt spray electrochemical corrosion conditions; Multiple stages can be used in series within the allowable pressure range, and the allowable larger working pressure is 3.6Mpa. This series of slurry pump products have the advantages of reasonable structure, high efficiency, reliable operation and convenient maintenance,

It is widely used in electric power, metallurgy, mining, coal, building materials, chemical industry and other industrial sectors to transport abrasive or corrosive slag slurry, especially power plant ash.

Hundreds of customers to choose from