7 * 24-hour service hotline

+86 15836191545

1.1 Purpose

The water ring pump is a liquid ring positive displacement pump with water as the medium (other liquids can also be used as the working medium, such as 98% concentrated sulfuric acid, oil, etc.). It has the characteristics of simple structure, reliable operation, convenient operation and maintenance, and wide use. It is suitable for pumping gases that do not contain solid particles, are insoluble in water, and have a temperature of - 10~60 ℃. It is used in paper making, tobacco, food, textile, metallurgy, mineral processing, coal, coal washing Gas drainage and chemical industry are ideal products for vacuum dehydration, vacuum drying, vacuum filtration and compressed gas. Because the gas compression process in water ring pump is close to isothermal compression, it is especially suitable for pumping flammable and explosive gases.

1.4 Product executive standards:

JB/T7255 ᚅ Water Ring Vacuum Pump and Water Ring Compressor

GB/T13929 | Water Ring Vacuum Pumps and Water Ring Compressors Test Methods

GB/T13930 \\\\\\\\\\\\\\\\\

1.5 Pump selection

1. According to the actual situation, the pump type shall be preliminarily determined by referring to the gas volume of the pump under different vacuum conditions in the performance table, the chemical properties of the pumped gas, and the requirements for the pump drive mode;

2. Further check the pump type according to the limit vacuum degree of the pump in the performance table, the working vacuum degree of the evacuated container and the requirements of the evacuated container on the background vacuum degree;

3. Gas volume selection: since the gas can be compressed, the gas volume parameters listed in the performance table are geometric parameters (volume flow), that is, the gas volume under the corresponding vacuum degree, and the gas flow follows the "P. Q=constant" law, so it is recommended to select the gas volume according to the following formula:

Q=(air outlet rate of the article+air leakage rate of the system)/P1

Q: It is the actual gas demand

P1: working vacuum (expressed in absolute pressure)

4. Attachment conditions: silencer is generally equipped when used as a vacuum pump, while the compressor is equipped with a steam separator; The motor power of the compressor increases with the increase of the discharge pressure. Pay attention to selecting a suitable motor; When the quality of circulating water is relatively hard, NaCI shall be added in the pool to obtain an electronic water treatment instrument; When two or more vacuum pumps are connected in parallel, soft start mode shall be adopted, or no load start device shall be configured.

5. The company can provide water supply, startup and shutdown drainage devices for customers to effectively prevent the pump from freezing and cracking during dry operation and shutdown in winter.

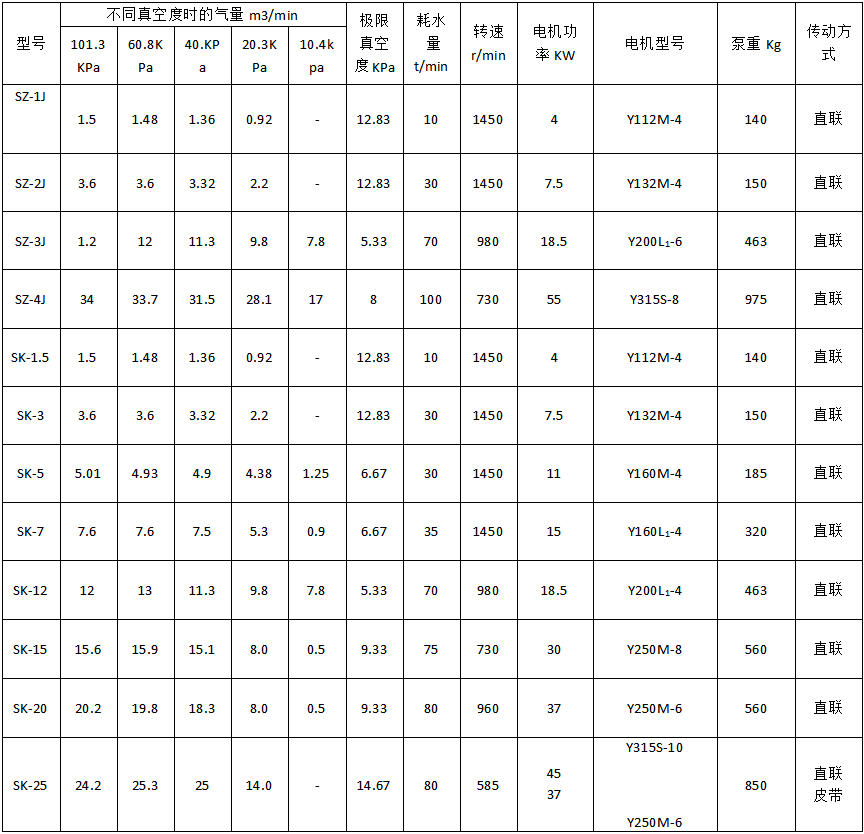

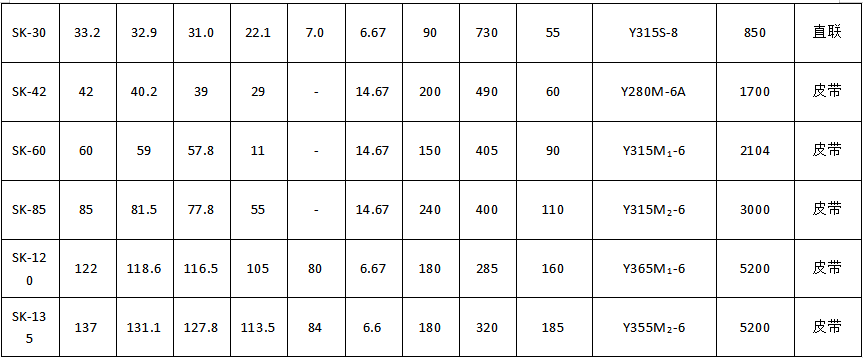

1.6 Main performance parameters (see table)

Table I Performance Parameters of Water Ring Vacuum Pump

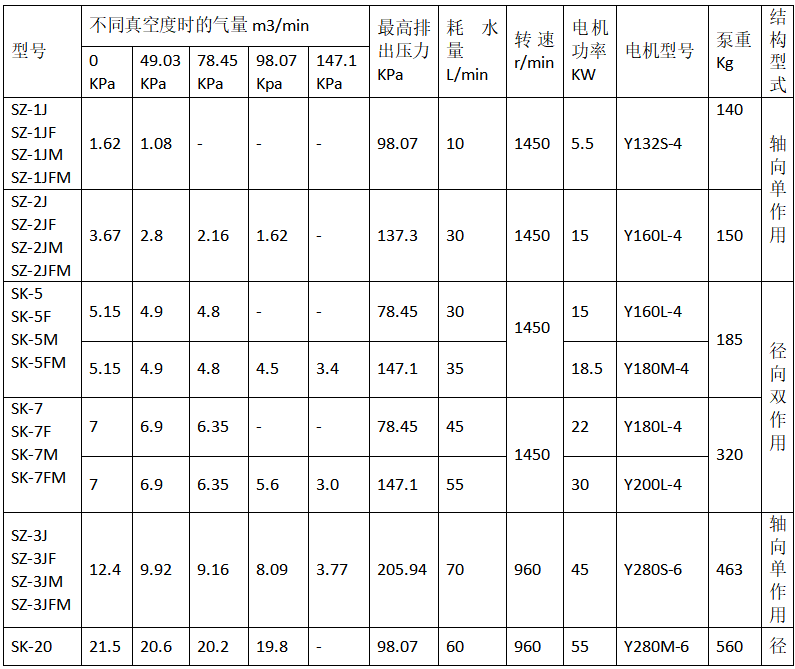

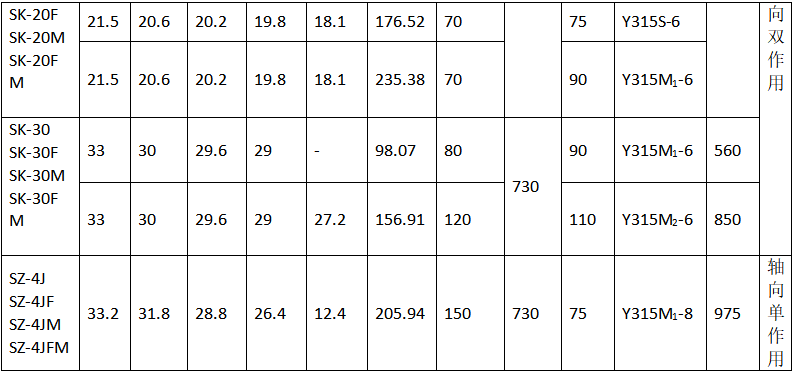

表2 水环式压缩机性能参数

(1)大气压: 101.33 kpa我生产的水环式真空泵及压缩机,产品规格和性能参数如表1,表2所示,表中所列性能参数为下列标准条件下的性能。

(2)吸入气体为空气,温度为20°C, 相对温度70%

(3)工作水温15°C。

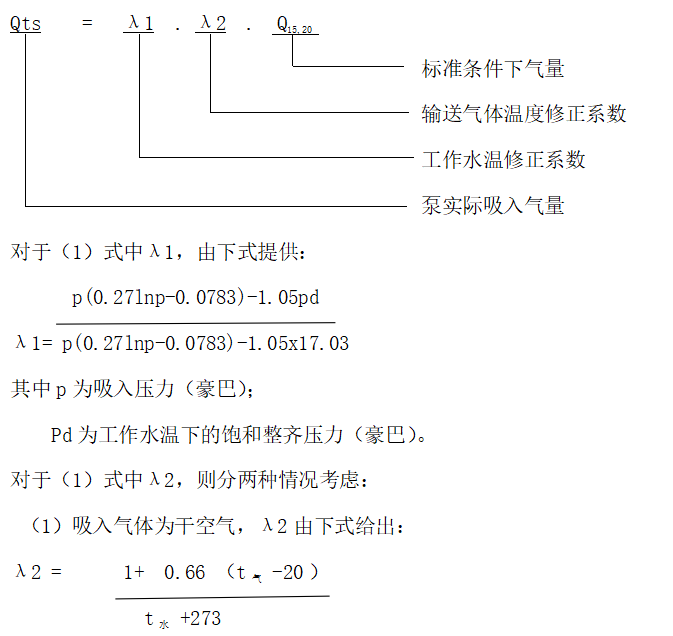

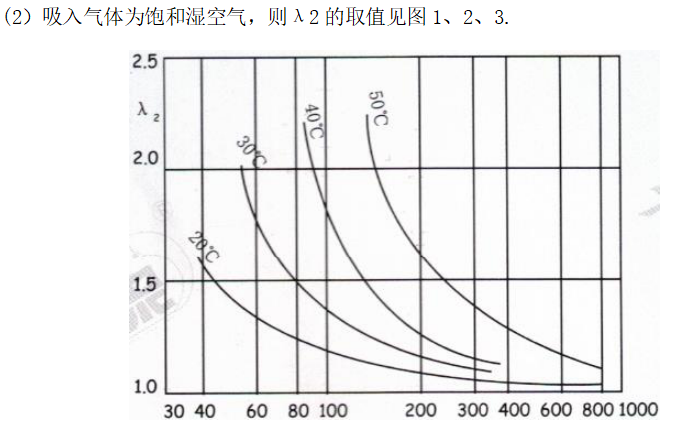

当设计选用时,请根据工艺实况,进行工作水温和输送气体温度修正,修正计算方法如下:

(1)工作水温修正(系数N1):当工作水温t水≠15°C时,因密封水的饱和蒸汽压力变化影响,泵的性能会有所不同,应予修正。

(2)输送气体温度修正(系数N2):当输送气体温度t气≠20°时泵的性能也会有所不同,也应予以修正。

故泵吸入的气量应按下式计算。

Note (vacuum pump): (1) Air volume refers to the intake air volume through the pump inlet when the inlet is at a given vacuum degree and the outlet is at atmospheric pressure of 101.33kpa;

(2) Vacuum degree is expressed by absolute pressure;

(3) When the working water volume exceeds the calibration value, the air volume will decrease and the shaft power will increase;

(4) When ordering the corrosion resistant pump, the transmission medium shall be provided.

Note (compressor): (1) Gas volume refers to the gas volume passing through the compressor inlet when the outlet is at a given discharge pressure and the inlet is at 101.33kpa atmospheric pressure;

(2) Discharge pressure is expressed by the difference between absolute pressure and atmospheric pressure;

(3) When the working water volume exceeds the calibration value, the air volume will decrease and the shaft power will increase;

(4) When ordering the corrosion resistant pump, the transmission medium shall be provided.

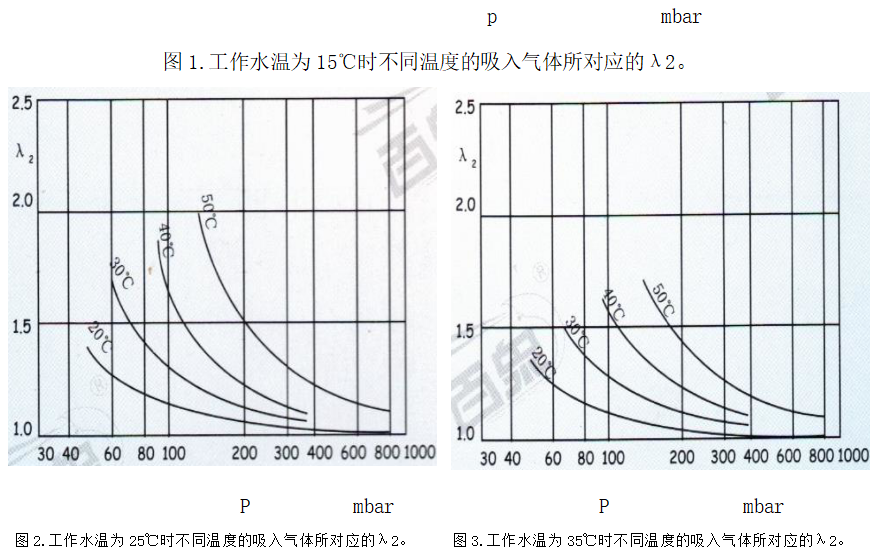

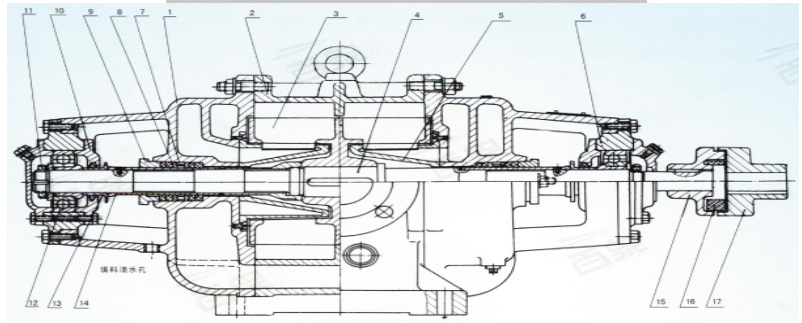

2、 Main structure description

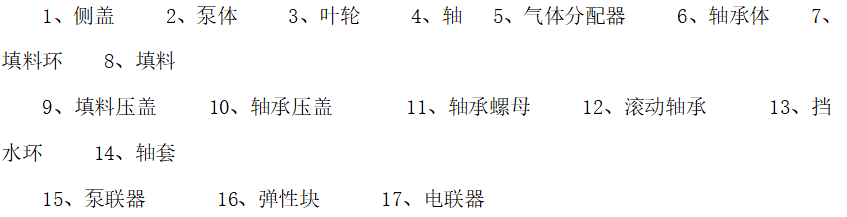

The water ring vacuum pump and compressor produced by our factory mainly have two structural forms: axial single acting water ring vacuum pump and compressor and radial double acting water ring vacuum pump and compressor. Their specific structures are shown in Figure 4 and Figure 5. The structural dimensions of the corrosion resistant pump are the same as those of the same type of pump.

The shaft seal generally adopts packing seal, and mechanical seal can also be used according to requirements.

SK pump has three transmission modes, namely, elastic coupling transmission, belt transmission and reducer transmission.

SZ type pump has only one transmission mode, that is, elastic coupling transmission.

Figure IV Structural Diagram of Axial Single Acting Water Ring Vacuum Pump and Compressor

图五 径向双作用水环式真空泵及压缩机结构示意图

3、 Working principle

Due to the relative eccentricity between the impeller and the pump body (as shown in Figure 6), a crescent space is formed between the water ring formed when the impeller rotates and the impeller contour, and is separated into several closed chambers with different volumes by the blades. With the rotation of the impeller, when the volume of the closed chamber is small to large, make it connected with the suction port, and the gas will be inhaled. When the volume of the closed chamber changes from large to small, the gas will be compressed to a certain extent, and make it connected with the exhaust port, and the gas can be discharged. The process (suction, compression, exhaust) can be repeated continuously to achieve the purpose of pumping (compression) gas. During operation, it is required to continuously supply water to the pump at a certain pressure (generally 78-147kpa gauge pressure) to supplement water ring consumption. The water supply shall be cooled and recycled, and the water quality shall be free from corrosion and scaling.

Fig. 6 Working Principle of Water Ring Pump

4、 Assembly, installation and adjustment

(1) Assembly

1. Assembly of axial single acting water ring vacuum pump and compressor

(1) Install the impeller on the shaft, measure the distance from the end face of the impeller to the shaft head, ensure the correct position of the impeller on the shaft, and then install each gear sleeve and shaft sleeve in turn according to the structural drawing. Pay attention to the rotation direction of the impeller when assembling, that is, from the transmission end, the blade bends forward in a clockwise direction, and protect the O-ring.

(2) Install the side cover and distribution plate together, and the relative position of the two is guaranteed by the positioning pin.

(3) Install the side cover distribution plate assembly, rotor and pump body together, and install the connecting bolts (do not tighten). When installing the rotor, pay attention to the matching of the impeller rotation direction and the suction and exhaust window (according to the working principle diagram), and do not install them reversely.

(4) Place the above components on the platform, make the feet on the same horizontal plane, and tighten the connecting bolts.

(5) Install the packing, packing ring, packing gland, inner end cover of bearing frame and bearing frame twice in turn.

(6) Install the bearing, set nut and bearing outer end cap in turn.

(7) The clearance between the impeller end face and the distribution plate shall be adjusted by the number of shims between the bearing frame at the non drive end and the end cover. After adjustment, the rotor shall rotate evenly without jamming.

(8) Install the water supply pipe and complete the assembly. The disassembly sequence is reverse to the assembly sequence.

2. Assembly of radial double acting water ring vacuum pump and compressor

Assemble as shown in structure drawing 5. Refer to the assembly sequence of axial single acting water ring vacuum pump and compressor, but pay attention to:

(1) When assembling the side cover and gas distributor, ensure the perpendicularity of the outer circle of the gas distributor and the end face of the side cover locating spigot to avoid friction between the outer circle of the gas distributor and the inner hole of the impeller after assembly, which will affect the operation performance.

(2) The gas distributor (A) and (B) shall not be installed reversely, otherwise the gas volume will be affected.

3. The mechanical seal shall be assembled in strict accordance with the assembly dimensions and relevant requirements of the mechanical seal, otherwise, the mechanical seal will be damaged.

(2) Installation

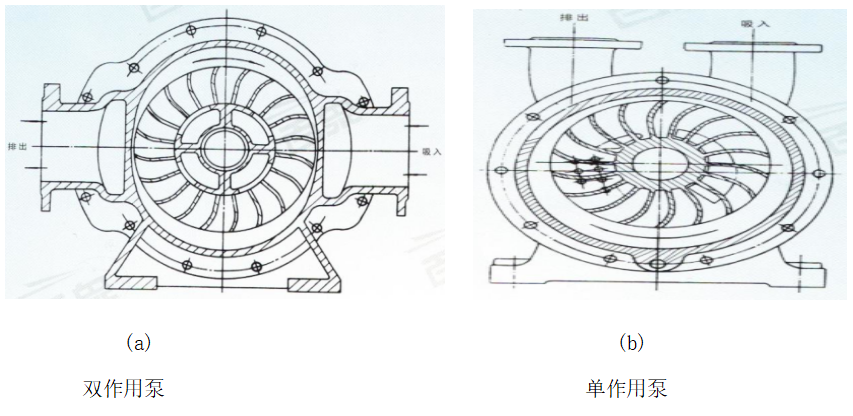

1. Installation and adjustment of pump and motor

First, install the pump on the base. Before installation, rotate the coupling by hand to check whether there is foreign matter stuck or other damage in the pump (when the complete set of equipment arrives at the installation site, it shall be disassembled, inspected, cleaned and assembled before installation, including damage and moisture during storage).

After the motor is fixed on the base, the coaxiality of the motor shaft and the pump shaft should be corrected. Generally, a ruler should be placed parallel to the axis line on the circumference of the coupling, and the upper, lower, left and right positions should be checked. It is required that the clearance between the ruler and the circumference of the coupling at any position should not exceed 0.3mm, and the axial clearance between the two couplings should be uniform. The clearance can be checked with a feeler gauge, which is generally 2-6m (see Figure 7)

Fig. 7 Method of Coaxiality Correction

After installing the pump and motor on the pump base, place the equipment on the foundation, adjust the level, and then tighten the anchor bolts.

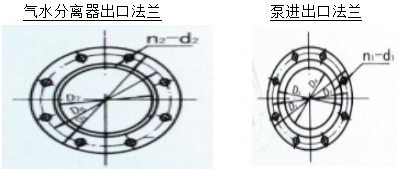

2. Installation of gas water separator or muffler

The installation of air-water separator or muffler shall be carried out according to the installation drawing. If it is necessary to change the installation, it shall be noted that the connecting pipe between the pump and air-water separator or muffler shall not be too long, and the change shall not be too fast, so as not to affect the performance.

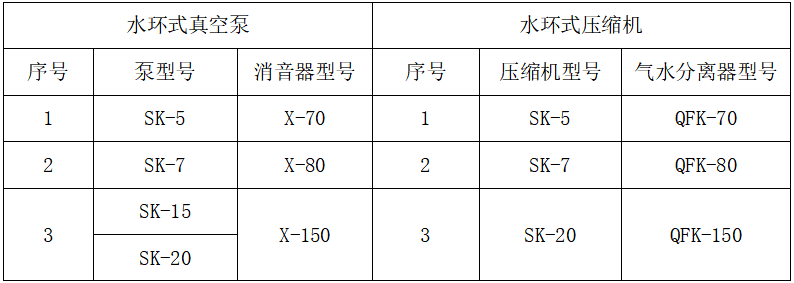

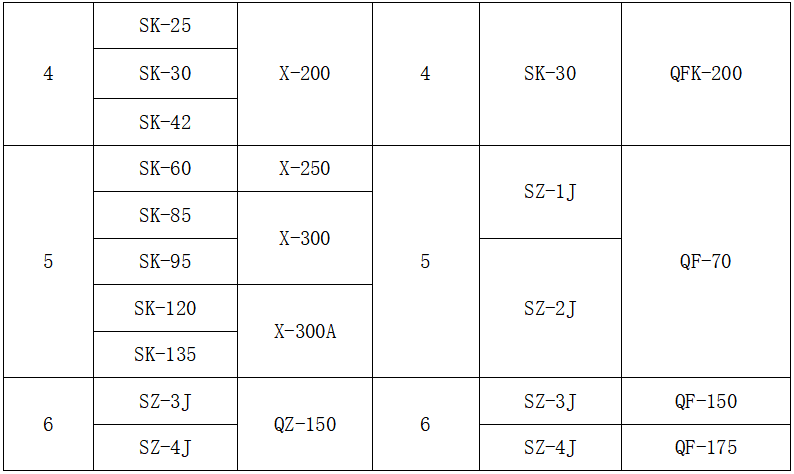

See Table 8 for the matching of the gas water separator and muffler with the pump: "List of the matching of the gas water separator and muffler with the pump

3. Pipeline installation:

When connecting the suction and exhaust pipelines and water supply pipelines, rust, welding slag and other sundries in the pipes must be removed before the pipes are connected. According to the process characteristics of the extracted gas, a filter or filter screen can be installed on the inlet pipeline to effectively prevent sundries from entering the pump to damage the impeller or affect the performance, so as to ensure the safe operation of the pump.

All gas pipelines shall have good sealing performance.

4. Gate valve installation:

The air inlet of vacuum pump or compressor and the outlet of gas water separator shall be equipped with gate valve. The water supply pipeline shall be equipped with regulating valve. Other valves required shall be determined by the user.

(3) Startup of vacuum pump:

1. Before starting the vacuum pump, the "five (one) start" clause shall be followed;

2. Before the pump is started, the valve of the water supply pipeline shall be opened first. After the pump is filled with water, the operation test can be carried out. It is not allowed to operate without water;

3. When a single pump is started, the air inlet pipe shall be fully ventilated to reduce the starting power. After the start, adjust the relevant equipment to make the pump work;

4. Multiple pumps are used in well connection, and the starting method should be soft start or no-load start. Our factory can provide customers with suitable starting auxiliary devices, which should be noted when ordering;

5. After starting, pay close attention to the current. If the current exceeds the rated current of the motor, contact the factory immediately and stop the pump for inspection;

6. If the belt is too loose after the belt driven pump starts and runs for several minutes, it will make abnormal noise. Stop the pump and tighten the belt to an appropriate position.

5、 Startup, operation and shutdown

(1) Start:

1. Check the coaxiality of motor shaft and pump shaft.

2. Rotate the coupling by hand to check whether the rotor rotates flexibly and whether there is jamming or friction.

3. Check whether all bolts are loose.

4. Check whether the lubricating grease of the bearing is sufficient.

5. Inject clean water into the water inlet pipe, wash it for five minutes, turn the rotor by hand, and then discharge the sewage.

6. Inject clean water with a pressure of about 78-147 kPa (gauge pressure) into the pump chamber and packing. The injection time is about 30 seconds. The time of small pump is slightly shorter than that of large pump.

7. Check the tightness of the packing to ensure that the sealing water drips down.

8. Open the inlet valve. If there is a vacuum regulating valve, close it. In principle, the pump is not allowed to be started directly under high vacuum. If it is necessary to start, it must be started as described in Method 2 of the above regulating mechanism.

9. Start the test (about 1 minute) to check whether the rotation direction of the motor is consistent with that of the water ring pump. If it is consistent, it can be started and operated normally. During operation, water should be continuously supplied to the pump chamber and the packing. The amount of water supplied to the pump chamber decreases slightly with the decrease of the vacuum degree or the exhaust pressure. The specific size should ensure that the discharge water temperature is not higher than 40 ℃, (For the newly purchased pump, after the normal startup, the operation test shall be carried out within the working range at the specified speed, and the test duration shall not be less than 30 minutes. During the test run, in addition to the inspection according to the following operating procedures, the sealing of the shaft seal and connection parts shall also be checked, and the pump can be put into operation only after everything is normal.). Dry running is strictly prohibited

(2) Running

The pump shall be observed and checked at any time during operation:

1. Whether the bearing is heated, the operating temperature shall not exceed the ambient temperature by 30, and the higher temperature (regardless of the ambient temperature) shall not exceed 75 ℃.

2. Whether the tightness of the packing is appropriate and whether the packing gland is hot.

3. Check whether the vacuum degree or exhaust pressure is normal and stable.

4. Whether the shaft power and speed are relatively stable.

5. Whether the make-up water volume is appropriate, and the drainage temperature should not exceed 40 ℃.

6. Check whether the running sound of the pump is normal and whether the pump vibrates.

(3) Parking

1. Close the valve on the air inlet pipe (if there is a vacuum regulating valve, open it).

2. Turn off the motor; Close the valve on the air water separator of the compressor.

3. Close all water supply pipelines.

4. If the pump is not used for more than two days, the open water pipe or the screw plug on the pump body must be opened to drain the water. If the pump is stopped in winter, the water must be drained to prevent the pump body from freezing and cracking.

6、 Repair and maintenance

1. Before the pump is assembled, the non machined surface in contact with water shall be coated with antirust paint, and the machined surface in contact with water shall be coated with antirust grease.

2. When the pump is stored, the suction and discharge ports shall be covered with cover plates.

3. If the pump is not used for a long time, the coupling should be rotated frequently to prevent rust.

4. The pump that works 24 hours a day shall be shut down every 15 days to flush all kinds of dirt in the pump with water.

5. Regularly check (at least once a month) the integrity of the external parts of the pump, such as the sealing and packing conditions, the fastening of various fasteners, and the elasticity of the coupling elastic block.

6. The water supply shall be cooled and recycled, and the water quality shall be non corrosive without scaling. If scaling is found, please remove and change the water in time.

7. After every 2000 hours of operation, replace the grease in the bearing body, clean the bearing at least once a year, and replace all the lubricating oil. Fill 2/3 of the space with grease, not too much.

8. After the pump has been running for one year, all the pumps shall be disassembled for inspection, focusing on whether the impeller, distribution plate and gas distributor have damage traces, whether various fit clearances (especially the axial clearance between the impeller and distribution plate, the radial clearance between the inner hole of the impeller and the outer circle of the gas distributor) are normal, and whether the bearing wear is normal. In case of any abnormality, it shall be repaired or replaced in time.

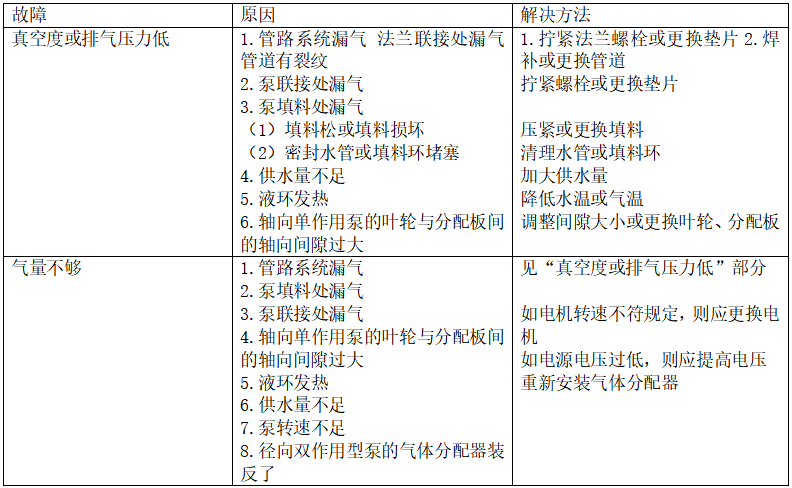

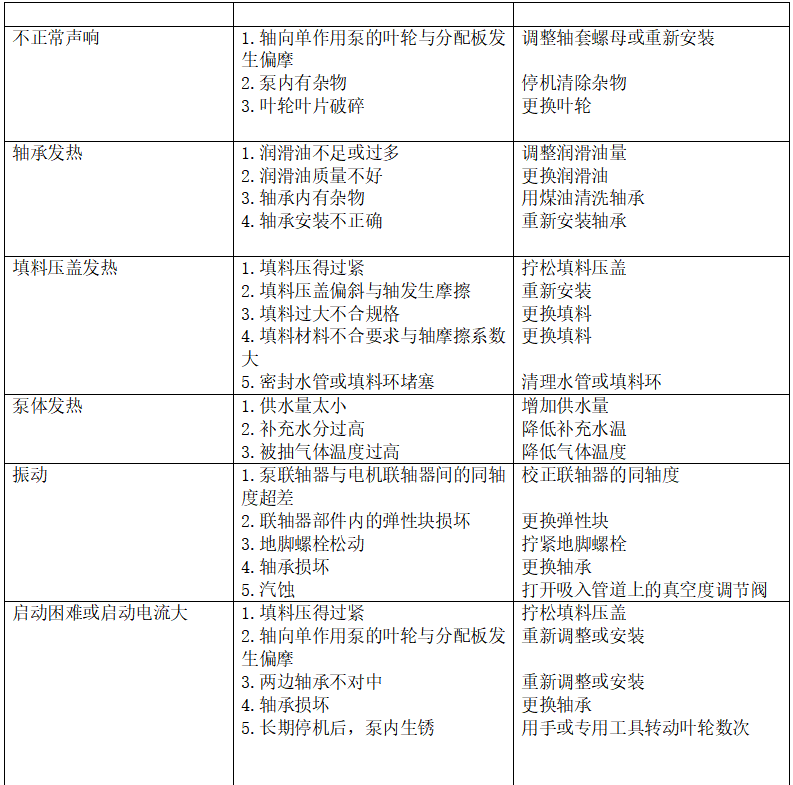

七、常见故障及解决方法

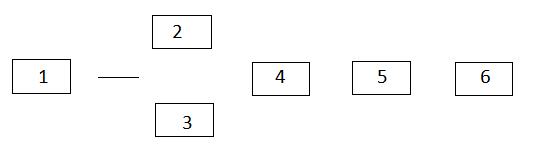

1:表示泵的型号;2:表示泵的设计序号;3:表示泵的较大气量m³/min;4:表示部级节能攻关更新换代产品;5:表示耐腐性;6:表示轴封形式;

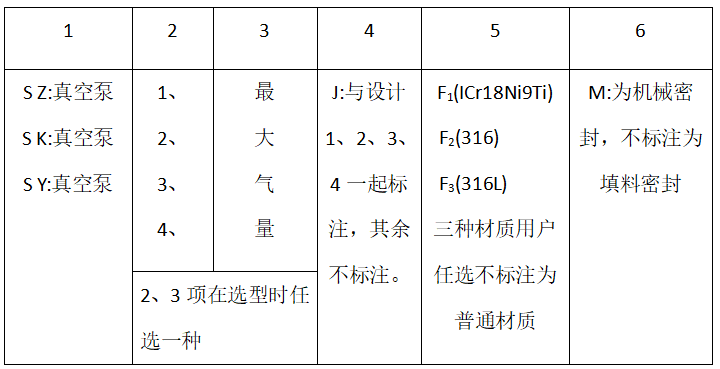

八、气水分离器和消音器同泵配表一览表

而水环式压缩机则须配气水分离器。注:水环式真空泵一般配消音器,如有特殊要求也可配同样规格的气水分离器,

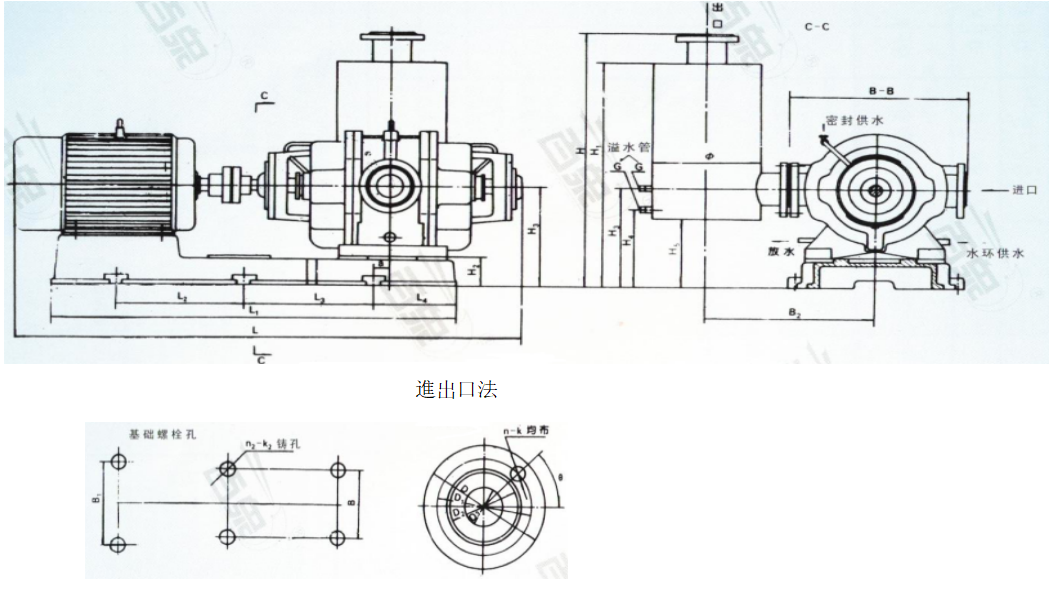

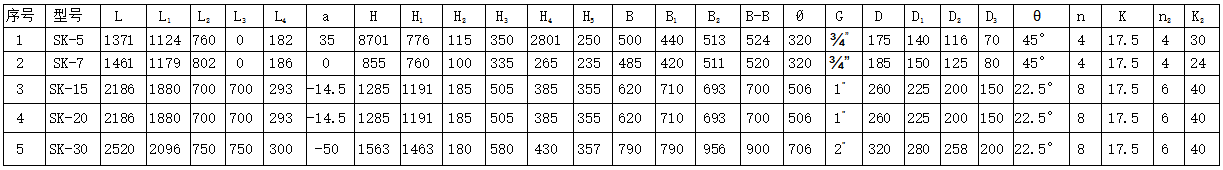

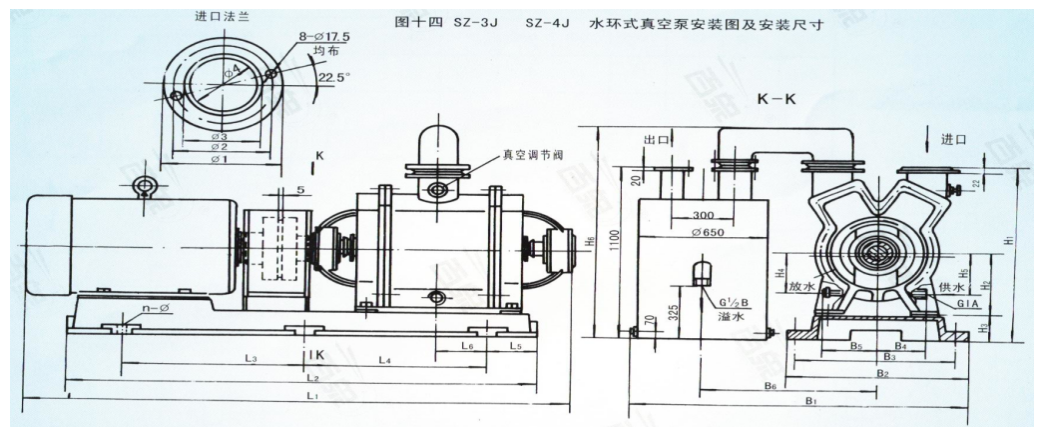

九、泵的安装图及安装尺寸

图八 SK-5、SK-7、SK-15、SK-20、SK-30水环式真空泵安装图

水环式真空泵安装尺寸表

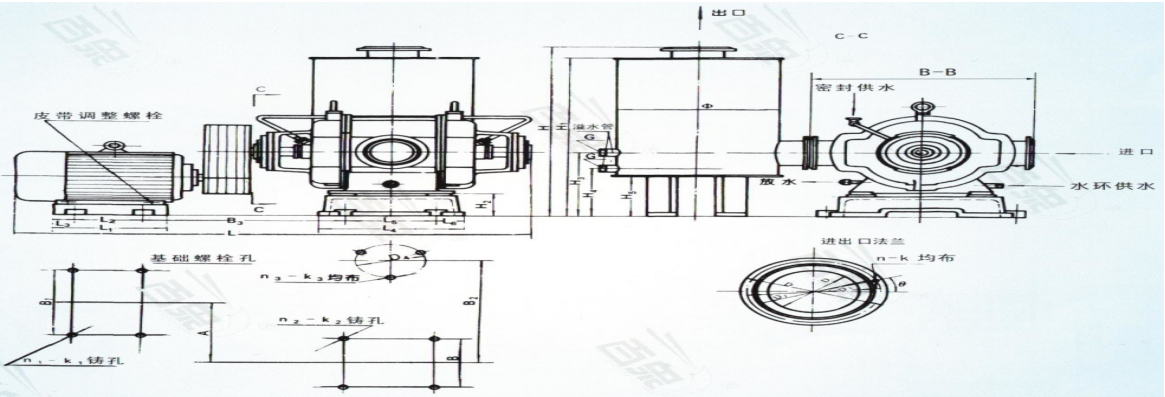

图九、SK-25水环式真空泵安装图

SK-25水环式真空泵安装尺寸表

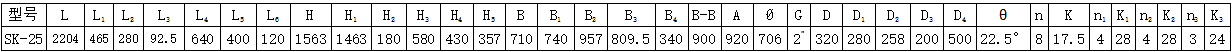

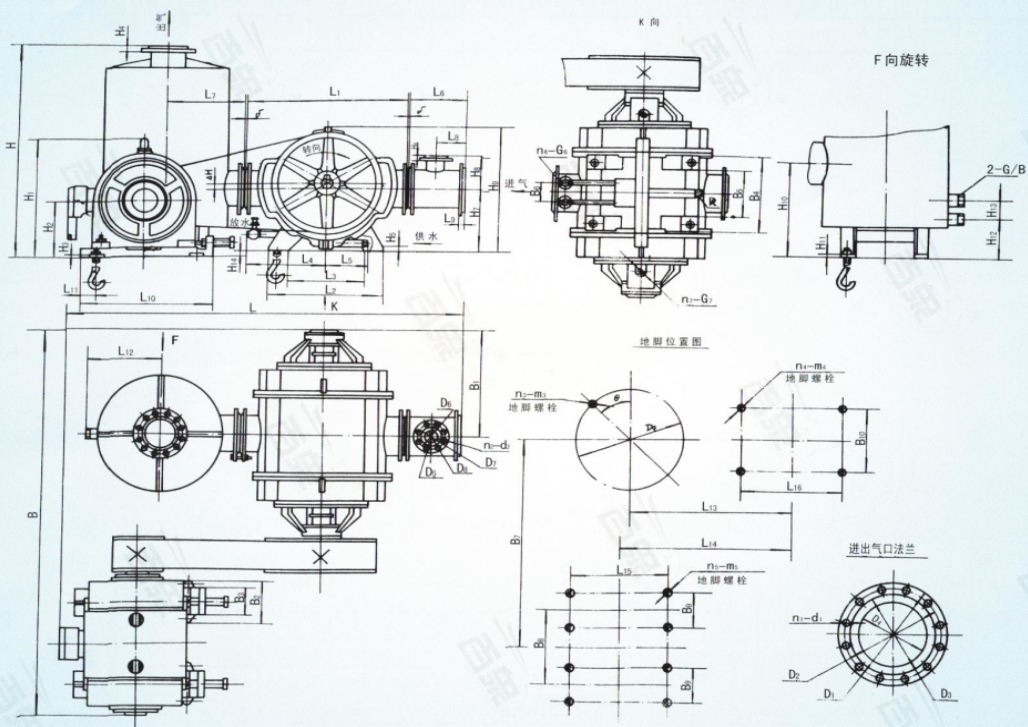

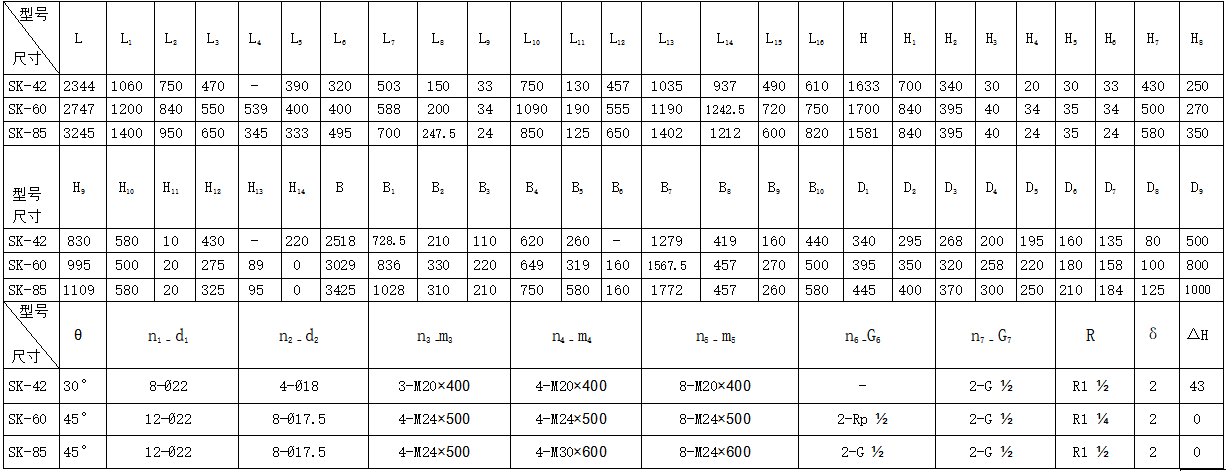

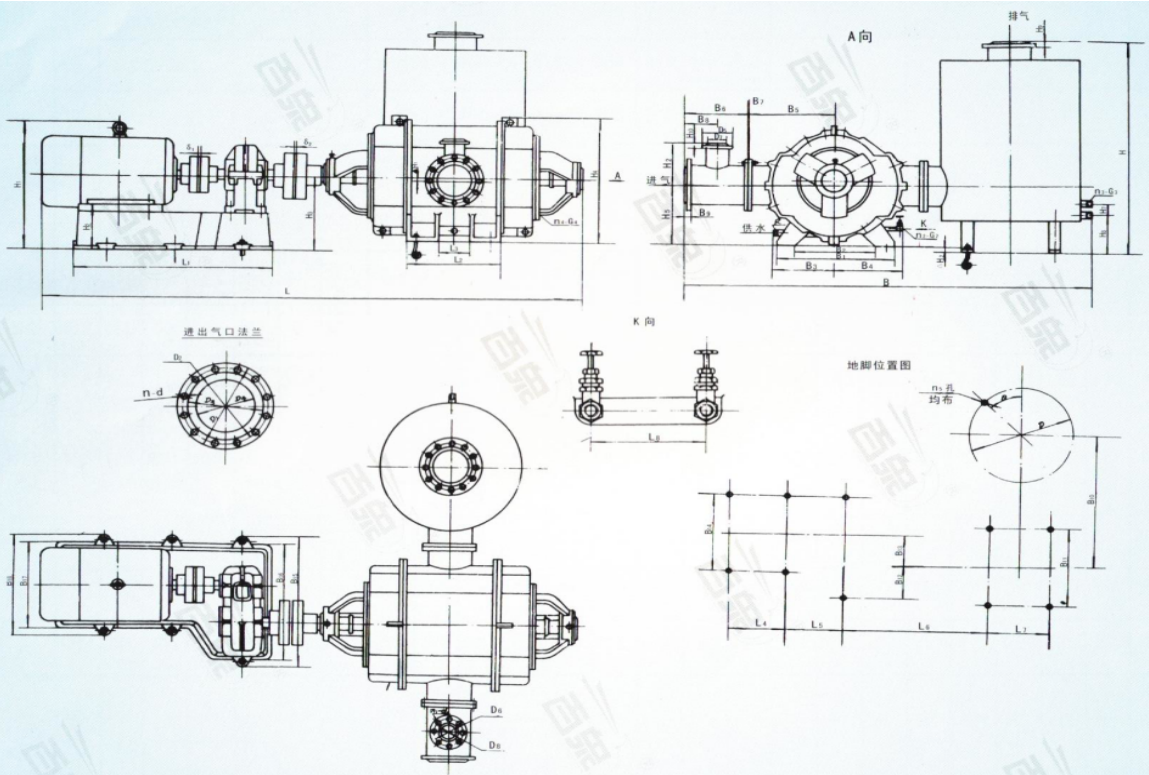

图十 SK-42、SK-60、SK-85水环式真空泵安装图(配皮带轮)

图十一 SK-42、SK-60、SK-85水环真空泵安装图(减速机)

SK-42、SK-60、SK-85水环式真空泵安装尺寸(配减速机)

图十二 SK-120、SK-135水环真空泵安装尺寸

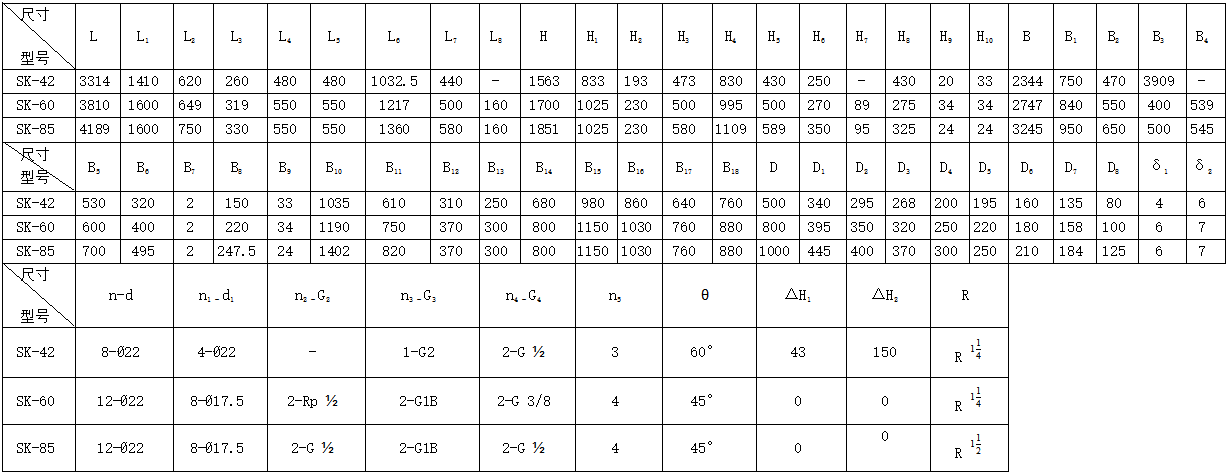

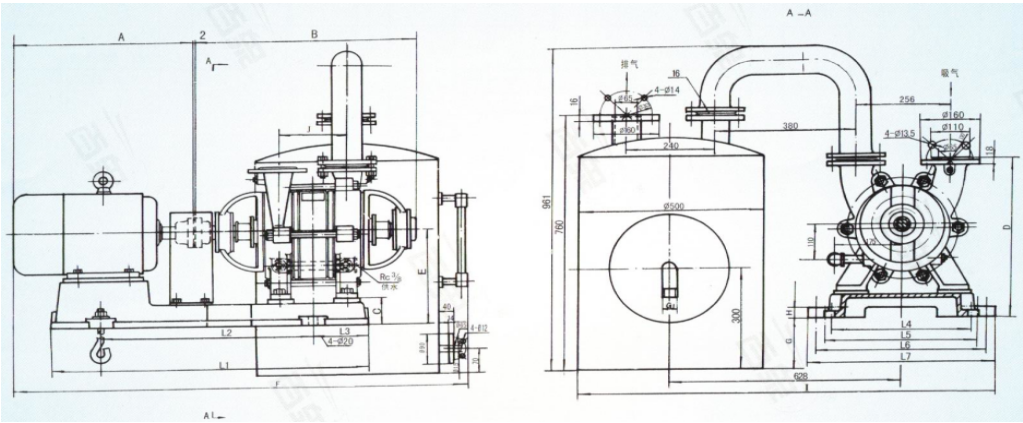

图十三 SZ-1J SZ-2J 水环式真空泵安装图及安装尺寸

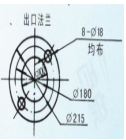

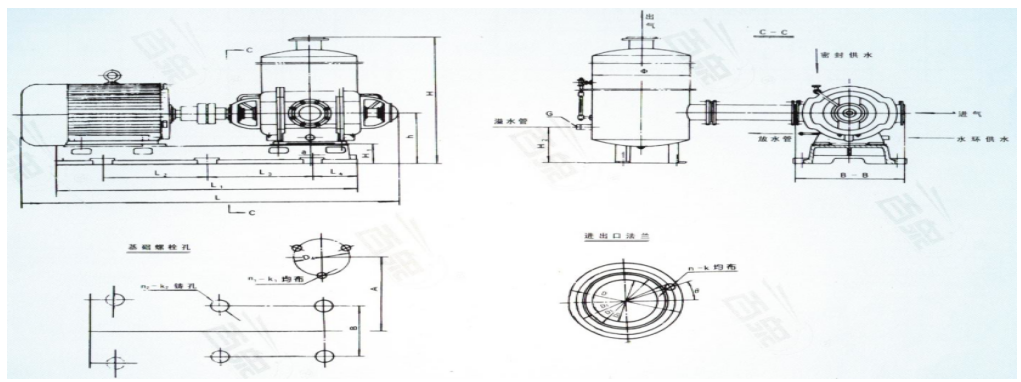

泵安装图及安装尺寸

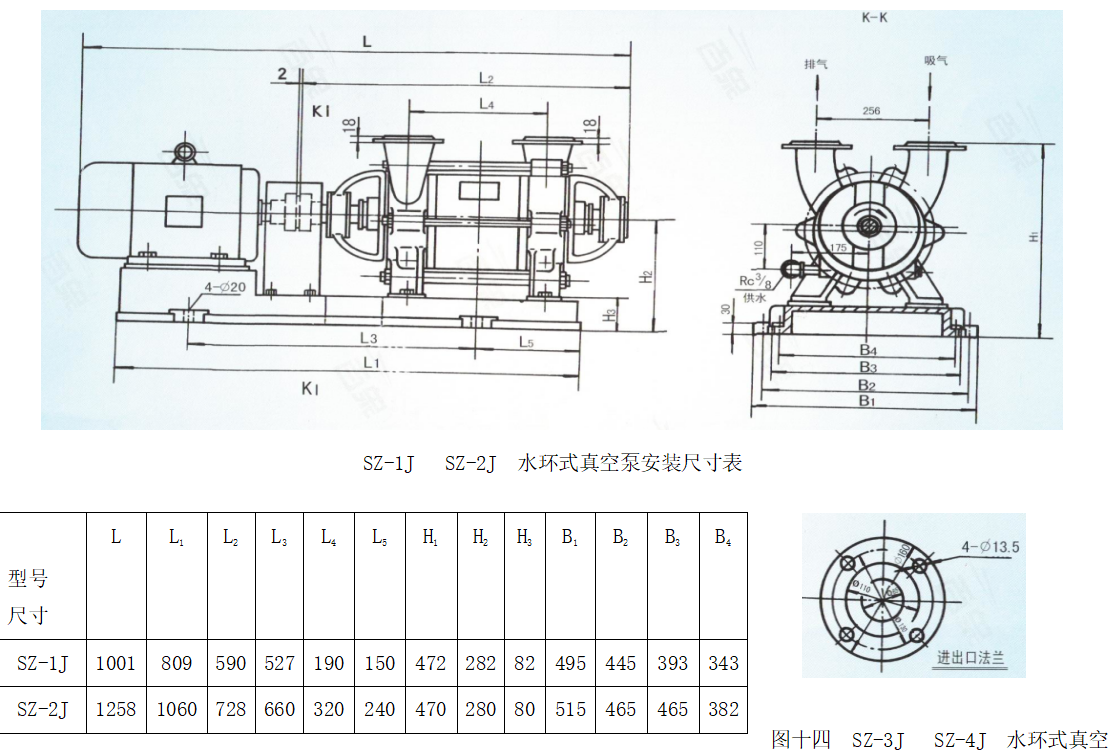

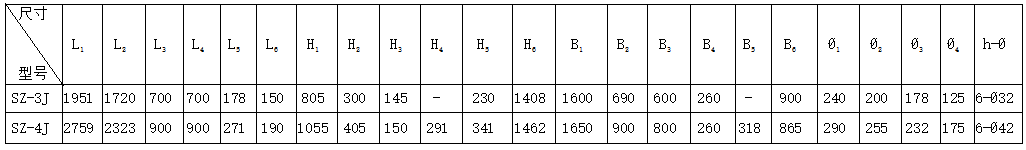

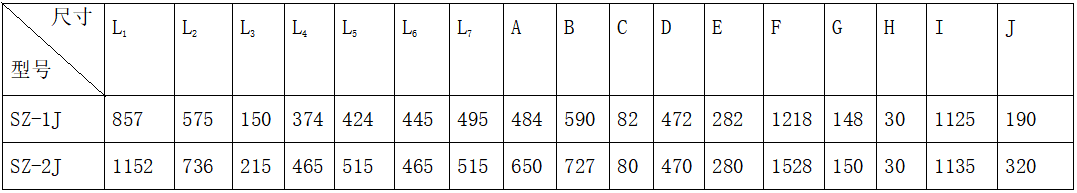

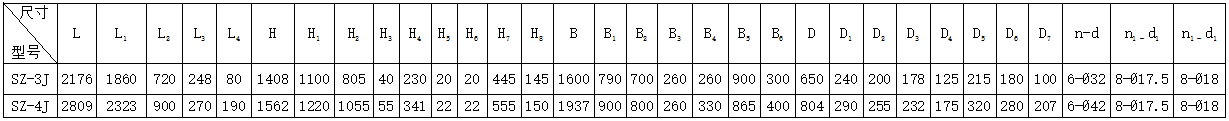

SZ-3J SZ-4J 水环式真空泵安装尺寸表

SZ-3J SZ-4J 水环式真空泵安装尺寸表

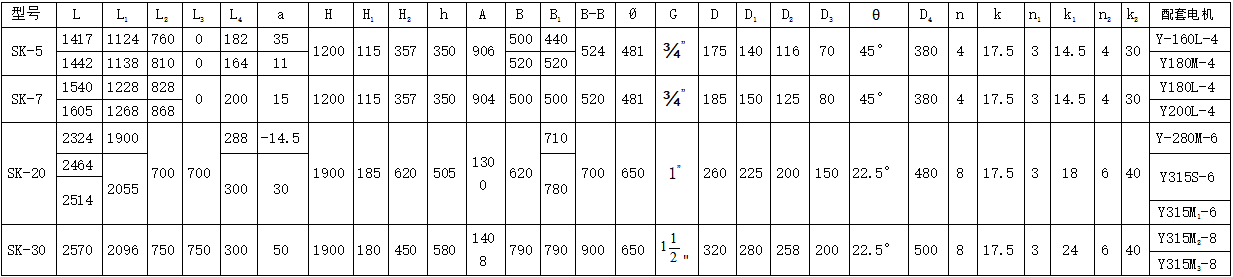

图十五 SK-5、SK-7、SK-20、SK-30水环式压缩机安装图

水 环 式 压 缩 机 安 装 尺 寸 表

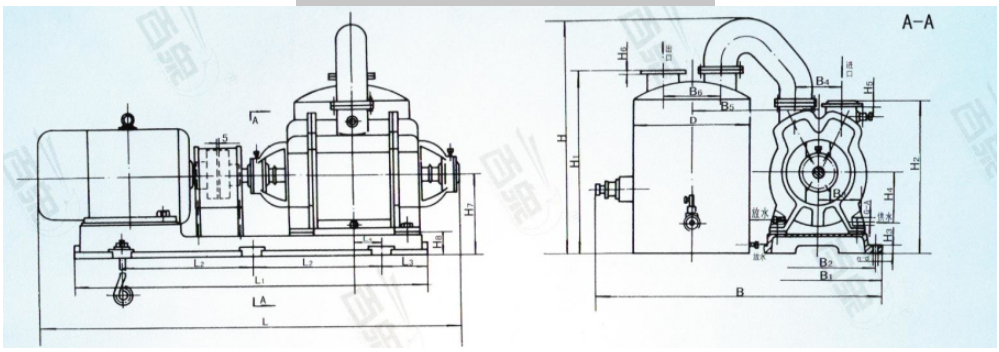

图十六 SZ-1J 、SZ-2J 水环式压缩机安装图

水 环 式 压 缩 机 安 装 尺 寸 表

图十七 SZ-3J 、SZ-4J 水环式压缩机安装图

水 环 式 压 缩 机 安 装 尺 寸 表

a. Isothermal compression, which can completely pump flammable and smokey gas;

b. In series with Roots vacuum pump, the product can be dried quickly at room temperature;

c. Double acting structure pump, rotor radial force balance, reliable operation, long service life;

d. Diversified materials can meet the requirements of various working conditions;

e. The shaft seal adopts two types of packing seal and mechanical seal, which can be selected by the user:

f. High efficiency and energy conservation;

Hundreds of customers to choose from