7 * 24-hour service hotline

+86 15836191545

Product Overview

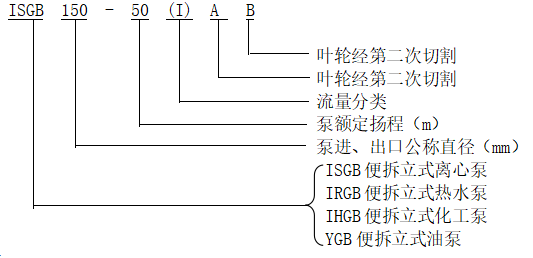

ISGB detachable vertical pipeline centrifugal pump is a product with novel structure and advanced technology developed on the basis of ISG pump.

The vertical pump has a bold breakthrough design especially in the overall structure. Independent bearing body and pump shaft support are adopted to solve the shortcomings of the original vertical pump supported by motor bearings; The impeller of hydraulic model is used to eliminate the shortage of large axial force of the original vertical pump; Y series standard universal motor is adopted to solve the problem of difficult replacement of the original vertical pump extended shaft motor; At the same time, the 100% removable structure solves the problem of replacing the bearing, mechanical seal, impeller and pump shaft of the high-power water pump.

The pump has the irreplaceable advantages of stable operation, long service life, more convenient matching, easier maintenance, etc. Among the vertical pump series products, it is among the top in China, and is an ideal product to replace ISG type vertical pump, IS type centrifugal pump, S type double suction pump and other conventional centrifugal pumps.

1. The vertical structure is convenient for installation and commissioning. The specially designed motor and pump body are connected by a connector, which has high concentricity and high processing accuracy. The floor area is greatly reduced, reducing the construction investment of the pump room by 30% - 60%. The solid footing, compact structure, exquisite casting and appearance treatment endow the vertical centrifugal pump with a new aesthetic feeling, making the product glow with artistic charm, which can be comparable to the vertical pump of foreign famous manufacturers.

2. It is equipped with Y series standard universal motors produced by famous domestic manufacturers, with stable operation and low noise.

3. The bearings are precision bearings of international famous brands with high precision, good reliability and long service life.

4. The impeller adopts the hydraulic model of self balancing axial force in 1990s, which greatly extends the service life of pump bearing and mechanical seal.

5. The bearings in the motor bearing block are equipped with oil filling holes and oil drain holes, which are very convenient for bearing maintenance.

6. The removable rigid intermediate coupling makes the pump start without vibration and noise. The rotating part is equipped with a reliable safety shield, which is extremely safe.

7. The mechanical seal is made of stainless steel, tungsten carbide, fluorine rubber and other materials, which is resistant to high temperature and pressure, has a long service life, no leakage, no wear on the shaft, and ensures a clean working environment.

8. The pump cover has a unique structural design. As long as the hard intermediate coupling and pump cover nut are removed, the bearing pedestal, pump cover, pump shaft, impeller and other assemblies can be easily taken out to replace the mechanical seal and impeller without dismantling the motor, pump body and pipeline

Hundreds of customers to choose from